TM 1-1500-204-23-2

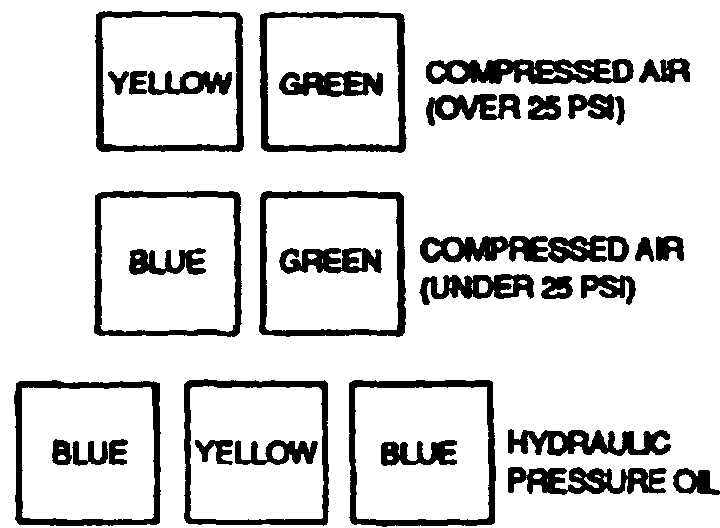

Figure 4-1. Printed - Symbol identification Tape.

d.

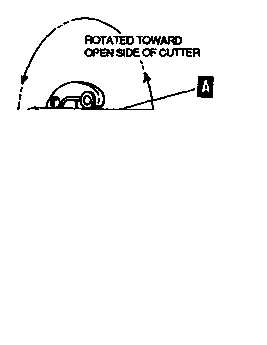

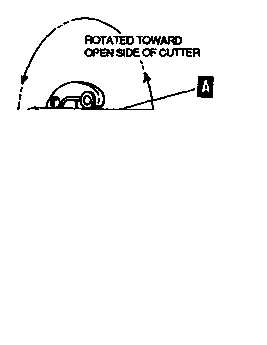

Cutting Tubing, To ensure a good flared tubing

connection, tubing should be cut squarely, and the end

deburred before it is flared (see figure 4-3). The standard

tubing cutter is clamped over tubing and rotated toward

its open side as cutting wheel is gradually fed into tube

by turning thumbscrew. The cutting wheel should be fed

into the tube only while the cutter is being rotated, as

dents will be caused in tubing if the cutter is note moving.

Moderate or light tension on thumbscrew will prevent

bending and excessive burrs on tubing. If a cutter is not

available, a hacksaw blade with 32 teeth per inch can be

used.

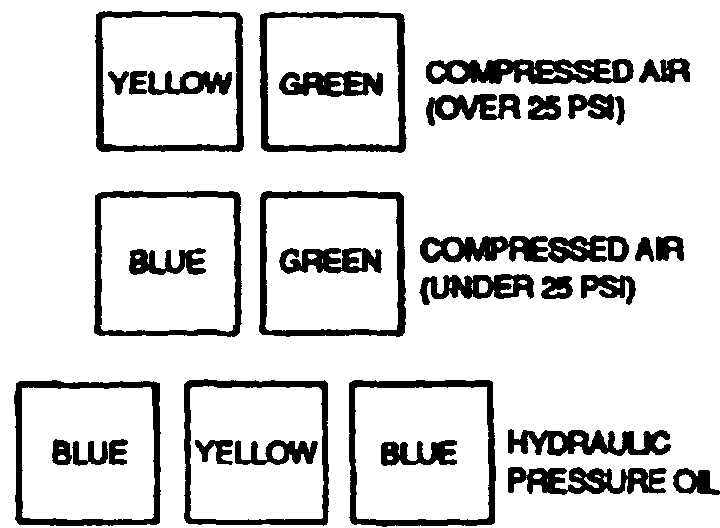

Figure 4-2. Solid Color Band Identification.

burnishing with hand tools. Nicked tubing is not only

weaker as to internal pressure, but such nicks must be

burnished out to reduce a notch effect. If nicks are not

burnished out, concentration under vibration will cause

weakening and breaking at nicked point. Burnishing re-

moves notches by removal of surrounding material. Bur-

nishing is not allowed in the heel of bends where material

has already been stretched thin during forming. Where

tubing is used for fluid’s (liquid or gaseous) at atmospher-

ic pressure or less, bursting strength of tubing is unimpor-

tant and, therefore, dents and nicks may be disregarded

providing that the tubing is structurally sound for its spe-

cific application, internally unobstructed, and that is re-

mains leaktight at all times. Dents can be removed from

tubing by drawing a bullet through tubing. The diameter

of the bullet must be equal to or slightly less than the

inside diameter of the tubing.

Figure 4-3. Cutting Tube with Tube Cutter.

e.

Bending Tubing. Tubing may be bent with any

one of a variety of bending tools. The hand bending tool

is shown in figure 4-4. Bending in a smaller radius than

limits shown in table 4-1, or forming flattened, kinked,

or wrinkled bends should be avoided (see figure 4-5).

MIL-T-7081-6061T-6 aluminum tubing may be formed

through tubing processes by maintaining a 1-inch bend

radius for 1/4-inch and 3/8-inch tubing. All sizes above

3/8 inch will require the use of a mandrel to form. Bends

in 5/16 inch outside diameter oxygen tubing should

4-2

Change 1