TM 1-1500-204-23-9

pressure from O psi to the operating pressure of the

aircraft system. The outlet pressure is read on a gauge.

(3)

Safety practices and procedures. The

following special precautions should be observed when

using the nitrogen servicing unit:

· Be careful not to knock over the high pressure

cylinders.

· Open all valves slowly.

· Do not exceed the aircraft system pressure or

quantity limit when servicing.

· Close all valves when moving the hand truck.

· Protect the fittings from contamination.

(4)

Operating

procedures.

Consult

the

applicable servicing unit and aircraft maintenance

manual for detailed instructions. The following general

procedures pertain to the operation of the nitrogen

servicing unit:

(a)

Position the cylinder so the hose is

at full length but not stretched.

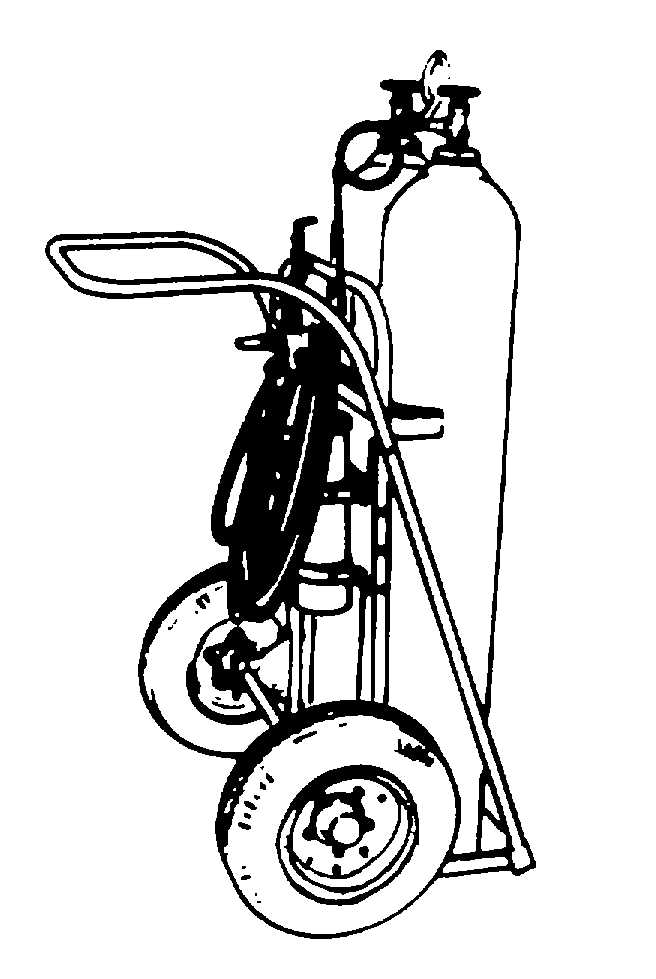

Figure 9-17. Nitrogen Servicing Unit

(b)

Determine pressure of system to be

serviced.

(c) Open shutoff valve.

(d)

Set pressure regulator to correct

pressure.

(e)

Use hose and service system.

(f)

On completion of servicing, close

shutoff valve, set pressure regulator to 0 psi, and roll up

hose.

(5)

Inspection. The operator should perform

the following general inspections before using the

nitrogen

servicing

unit.

Detailed

inspection

requirements are in the applicable maintenance manual.

(a)

Cylinders. Check for security on

hand truck.

(b)

Hose and fittings. Check for

tightness and leaks.

(6)

Maintenance. Consult the applicable

maintenance manual for scheduled and preventive

maintenance requirements.

k.

Hoists. Hoist shown in figure 9-18, can be

categorized as fixed height. The fixed height apparatus,

normally referred to as a hoist, is made of a welded,

tubular steel, truss-type construction. The legs on the

hoists are spreadable to straddle the equipment and

provide balance while lifting. Casters provide mobility,

allowing two people to handle the positioning of the

hoist.

(1)

Purpose. Hoists are designed to remove

and replace aircraft components during scheduled and

unscheduled maintenance. These components include

engines, transmissions, propellers, rotor blades and

rotor hubs. The amount of weight that can be lifted is

determined by the type, size of construction and the size

of the cable.

(2)

Types. Two general types of hoists are

described in the following paragraphs.

(a)

Manually-operated. On this type of

hoist, the winch is operated by hand. It main benefit is

the ability to be used at locations where power is not

available. Typically, the hoist will lift 5,000 pounds over

20 feet. It must be used on a paved surface.

9-45