NAVAIR 01-1A-505-2

006 02

TO 00-25-255-1

Page 5

TM 1-1500-323-24-2

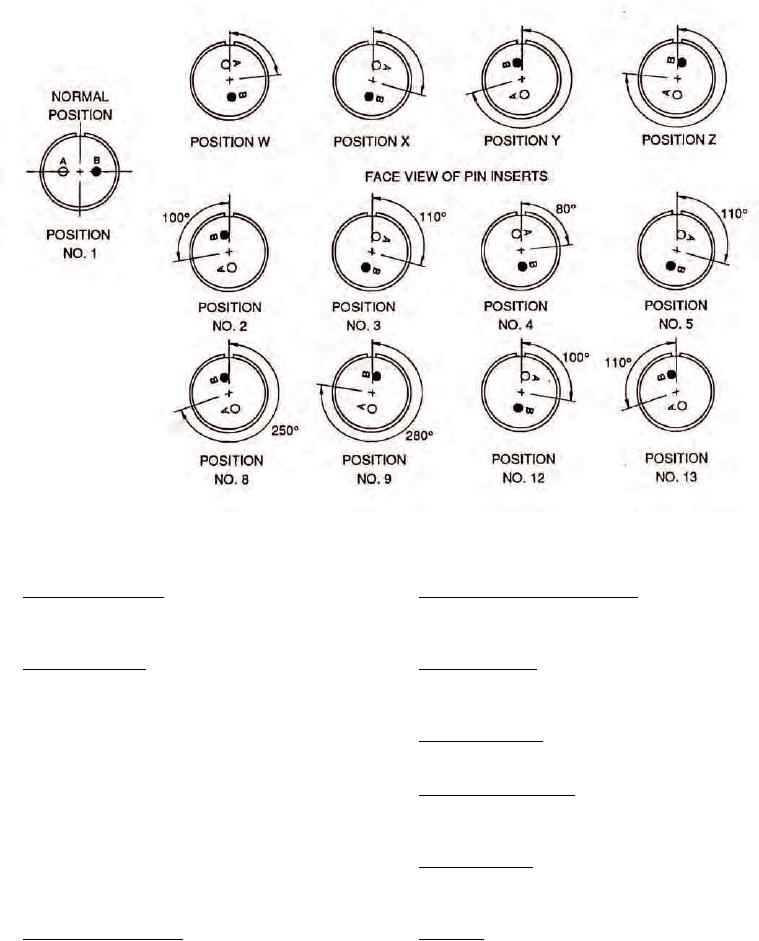

Figure 3. MIL-C-83723 Series II Alternate Positions

17. Insert Configuration. The insert configuration is

22. Closed-Entry Socket Contacts. These contacts

the insert arrangement by number and size of contacts

eliminate damage from abuse by test probes and help

used.

to correct any misaligned pins during engagement.

18. Alternate Position. The alternate keyway position

23. Contact Insertion. Insertion is accomplished from

indicates insert polarization (Figure 3).

the rear of connector. When the contact is fully inserted,

the clip tines snap securely behind the contact shoulders.

19. DESIGN AND CONSTRUCTION. Connectors and

accessories are designed and constructed to withstand

24. Contact Extraction. Extraction is accomplished with

normal handling incidental to installation and

the use of a removal tool.

maintenance (Figure 4).

25. Contact Retaining Clip. The contact retaining clip

20. INSERTS. The nonresilient material used for all

is completely encased in a tough plastic wafer to protect

inserts shall be a high grade dielectric having electrical

clip from damage.

and mechanical characteristics suitable for the purpose

intended. The impact strength shall be such that

26. Moisture Sealing. Complete sealing is achieved by

material shall not chip, crack, or break during assembly

combining four seals, shell, peripheral, interfacial, and

or normal maintenance.

wire seal.

21. Crimp Snap-In Contacts. Snap-in contacts designed

27. Shell Seal. This seal is effected when the plug shell

to AS39029 can be crimped with standard M22520/1

pushes against the sealing ring inside the receptacle

crimp tool.

when connectors are mated.