NAVAIR 01-1A-505-2

006 02

TO 00-25-255-1

Page 36

TM 1-1500-323-24-2

45. CONNECTOR BUILD-UP.

46. WIRE DIAMETER BUILD-UP. If wire outside

diameter is not large enough to fill wire sealing grommet

holes, build-up wire outside diameter by applying

heat-shrinkable insulating sleeving. This must be

accomplished prior to contact insertion.

47. WIRE STRIPPING. Strip wire in accordance with

following procedure:

a. Cut wire to proper length. Ensure enough wire

remains for adequate strain relief without leaving excess

slack.

b. S t r i p i n s u l a t i o n f r o m e n d ( N A V A I R

01-1A-505-1, WP 009 00). Select contact (Table 3 or 4).

48. CONTACT CRIMPING. Crimp contact in

accordance with following procedure:

a.

Select correct crimp tool (Table 5).

b. Perform die closure check, install positioner,

and set selector knob for gage of wire.

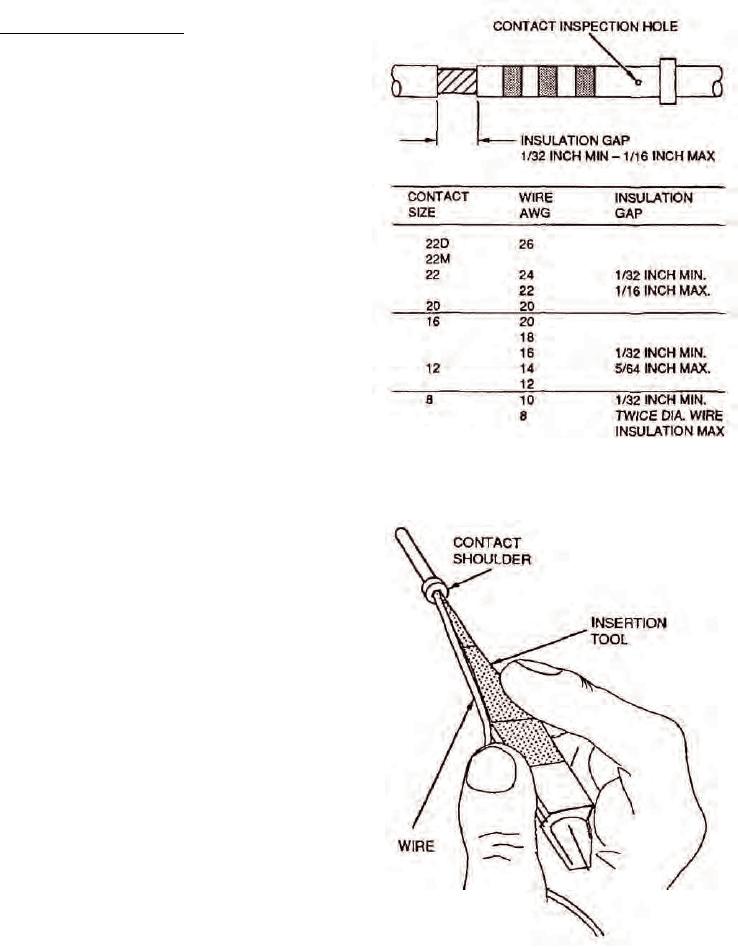

Figure 8. Insulation Gap

c.

Insert stripped wire into contact conductor

barrel. Ensure all wire strands are inside contact

conductor barrel and visible in contact inspection hole

(Figure 8).

d. If insulation gap is too large, trim conductor as

required. If insulation gap is too small, trim insulation

as required.

e.

Crimp contact to wire.

49. CONTACT INSERTION. Insert wired or unwired

contacts in accordance with following procedure:

a. Remove sealing plug and/or contact from

contact cavity (Paragraph 53.)

b. Ensure wire or cable on contact is routed

through connector backshell.

c.

Select correct insertion tool (Table 5).

d. Place wire and contact assembly into colored

tip of insertion tool (Figure 9). Ensure tool tip is over

conductor barrel and butted against contact shoulder.

Figure 9. Inserting Contact into Insertion Tool