NAVAIR 01-1A-505-2

010 02

TO 00-25-255-1

Page 9

TM 1-1500-323-24-2

16. POLARIZATION. Connectors are polarized as

denoted by their part numbers. This means that the

master keyway is rotated to prevent mis-mating of

similar connectors in a similar location. A plug with a

given polarization letter will mate with a receptacle

with same letter. The inserts do not rotate, only the

keyway is rotated.

17. PART NUMBER. The following paragraphs contain

information necessary for proper selection and

procurement of connector (Figure 3).

18. Basic Part Number. The prefix denotes the basic

specification.

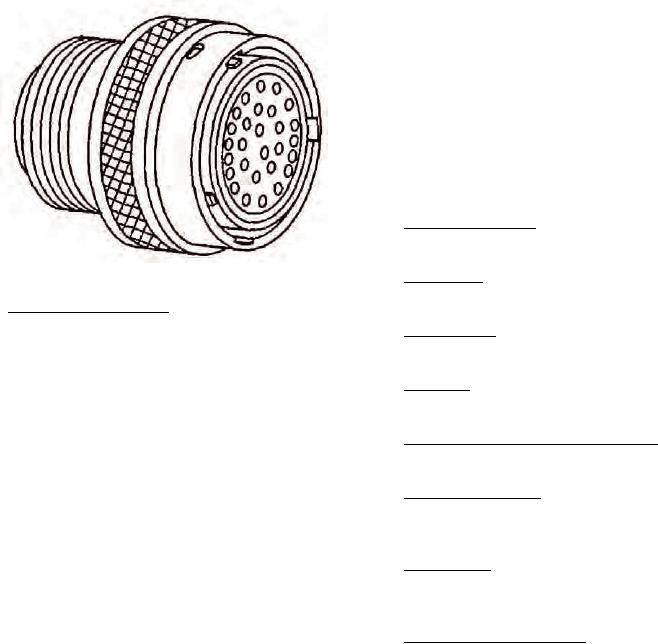

Figure 2. MIL-C-81703 Series I Typical Connector

19. Shell Style. The shell style denotes type and

mounting of connector.

10. MIL-C-81703 SERIES 1.

20. Service Class. The service class is a letter code

11. MIL-C-81703 Series 1 connectors are push-pull

denoting environment resistant ability.

coupled with solder contacts. Series I hermetic box and

solder mount receptacles are also available. The Series

21. Shell Size. Shell size is indicated by a progressive

I connector has a temperature range of -67F (-55C) to

numbering system.

+257F (+125C) (Figure 2).

22. Contact Termination (Hermetics only). The contact

12. GROMMET SEALING PLUGS. The grommets of

indicates type of solder termination.

environment resisting connectors are designed to accept

sealing plugs in accordance with MIL-C-81703 to be

23. Insert Configuration. The insert configuration is the

used where unwired contacts are placed. The connector

insert arrangement by number and size of contacts

when ordered as a unit will have sealing plugs enclosed

used.

to equal 15 percent of the number of contacts but not

less than one.

24. Contact Style. The contact style denotes pin or socket

contacts and whether or not the connector is supplied

13. MATING SEAL. Plugs and receptacles with pin

with contacts.

inserts have a resilient face with individual pin barriers

to seal against the bard face socket insert. The resilient

25. Alternate Keyway Position. The alternate position

interface seal provides individual contact seals in mated

indicates insert polarization (Figure 4).

condition between each contact and shell.

26. DESIGN AND CONSTRUCTION. Connectors and

14. SHELL. Shells including mounting flanges are of

accessories are designed and constructed to withstand

one-piece construction and designed to retain their

normal handling incidental to installation and

inserts in one position by mechanical means. The shell

maintenance.

is designed to accept and retain a cable adapter or other

accessory.

27. CONTACTS. Contact are fixed, non-removable, and

solderable.

15. COUPLING. The two methods of coupling are push-

pull and rack and panel coupling.