NAVAIR 01-1A-505-2

010 02

TO 00-25-255-1

Page 16

TM 1-1500-323-24-2

86. Interfacial Seal. This seal is achieved by insulator

faces meeting when the plug and receptacle are mated.

87. Wire Seal. This seal is accomplished by a multiple

ripple design, exceeding wire sealing requirements of

MIL-C-81703.

88. Insert Retention. Insert retention is accomplished

by a hard plastic wafer firmly locked into a groove in

the shell and a strong adhesive bond between the insert

and shell.

89. Keying. Keying is used in shell-enclosed connectors

to obtain polarization, which ensures correct location

when mating a connector (Figure 11).

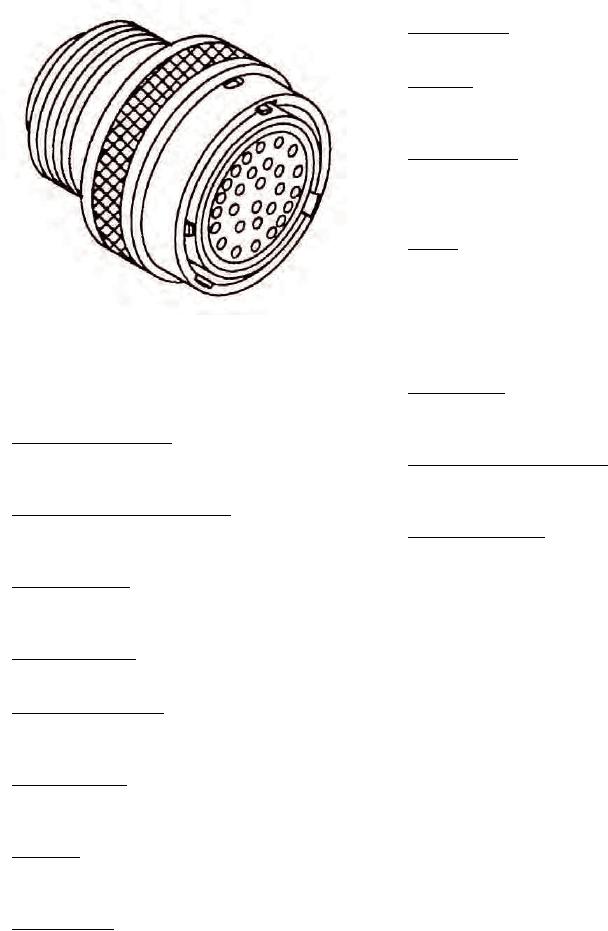

Figure 9. MIL-C-81703 Series 3 Typical Connector

90. CONTACTS. Contacts are designed to prevent

damage to contact retention device or sealing member

77. DESIGN AND CONSTRUCTION. Connectors and

during insertion or removal of contacts.

accessories are designed and constructed to withstand

normal handling incidental to installation and

91. Fixed Contacts. Contacts in some hermetically sealed

maintenance.

receptacles are fixed non-removable, and solderable, or

feed through.

78. Crimp Snap-in Contacts. Snap-in contacts designed

to AS39029 can be crimped with a standard M22520/1

92. Crimp Removable Contacts. Crimp removable

crimp tool.

contacts may be used with all environment resisting

classes of connectors.

79. Closed-Entry Socket Contacts. These contacts

eliminate damage from abuse by test probes and help to

93. Contact Availability. Crimp contacts are supplied

correct any misaligned pins during engagement.

with each connector unit package and consist of a full

complement plus one spare per size for connectors of 26

80. Contact Insertion. Insertion is accomplished from

contacts or less. Connectors with more than 26 contacts

rear of connector. When contact is fully inserted, the

will have two spares of each size used. Contacts may

clip tines snap securely behind contact shoulders.

also be ordered in individual quantities when necessary.

81. Contact Extraction. Extraction is accomplished with

94. CONTACT APPLICATION. Contacts used for Series

the use of a removal tool.

3 connectors are manufactured in accordance with

AS39029. The contact part number breakdown is

82. Contact Retaining Clip. The contact retaining clip is

illustrated (Figure 12). The Basic Identification Number

completely encased in a tough plastic wafer to protect

(BIN) or last three digits of contact part number, matches

clip from damage.

standard resistor color code (Figure 13).

83. Moisture Sealing. Complete sealing is achieved by

95. POWER CONTACTS. Power contacts are used to

combining four seals; shell, peripheral, interfacial, and

connect single conductor wire through connectors. The

wire seal.

power contacts range from size 12 through 20 and are of

crimp, rear release design. Contacts are listed by size.

84. Shell Seal. This seal is effected when plug shell

Match the required size to connector application, wire

pushes against sealing ring in receptacle when

gage, and composition. Socket and pin contact part

connectors are mated.

numbers are listed along with corresponding color

bands (Table 4).

85. Peripheral Seal. This seal is around the edge of pin

insulator and designed so that when mating connector,

tension is put on seal and greatly reduces compression

set.