NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

008 02

1 September 2011

Page 3

1.

INTRODUCTION.

2. This Work Package (WP) pertains to connectors

manufactured in accordance with MIL-DTL-83733.

NOTE

All the MIL-DTL-83733 connectors are

electroless nickel plated in accordance with

SAE-AMS2404. These connectors are not for

Navy or Air Force use. If replacement of

existing MIL-DTL-83733 connectors for

Navy or Air Force platforms is required,

consult responsible engineering authority.

3. DESCRIPTION. The connectors covered by

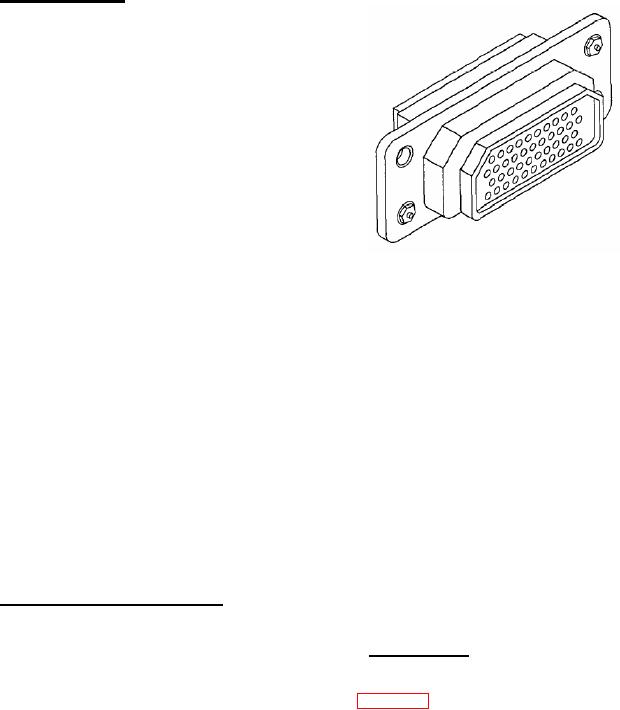

Figure 1. MIL-DTL-83733 Typical Connector

MIL-DTL-83733 have the following features:

a. Environment resistant at sea level and high

7. CONNECTOR SHELLS. The connector shells

altitudes.

are made from high grade aluminum alloy to form a

solid shell designed to positively retain inserts. The

b. Continuous operation at temperatures ranging

engaging skirts have a keystone shape to prevent

from -85F (-65C) to +392F (+200C).

mating when either connector is rotated 180 degrees

from the correct mating position.

c. A non-removable, integral, resilient peripheral

seal in the receptacle shell which will engage the

8. POLARIZATION. Polarization is accomplished

mating plug before mating is completed.

by a keystone shape shell design with polarization

accomplished before engagement of pins or sockets.

d.

Voltage service ratings I and II.

9. MOUNTING. Rack to panel connector shells are

e.

Fluid Resistant.

capable of being interchangeably mounted in a fixed or

floating position. Fixed mounted connectors will mate

f. Designed to prevent inadvertent electrical

properly with float mounted connectors. Shells are

contact and provide contact protection during mating.

provided with either captive clinch nuts for fixed

mounting of will be provided with or have provisions to

allow installation of spring mounts, bushings, or guide

4.

MIL-DTL-83733 CONNECTORS.

pins.

5. MIL-DTL-83733 connectors are environment and

10. Mounting Styles. Figure 2 provides mounting

fluid resisting, miniature, rectangular, rack to panel

styles for MIL-DTL-83733 connectors. Bushing and

electrical connectors, both military and commercial,

spring mount assemblies are separate accessories, refer

having pin and socket rear release, removable crimp

to WP 008 03.

contacts with fixed or float mounting (Figure 1).

11. PART NUMBER. The following paragraphs

6. SEALING PLUGS. The connector when ordered

contain information necessary for proper selection and

as a unit will have sealing plugs enclosed equal to ten

procurement of connector (Figure 3).

percent of the number of contacts, but not less than one

sealing plug per unit package. The sealing plugs are

used in both plugs and receptacles.