TM 10-4930-351-14

0028 00

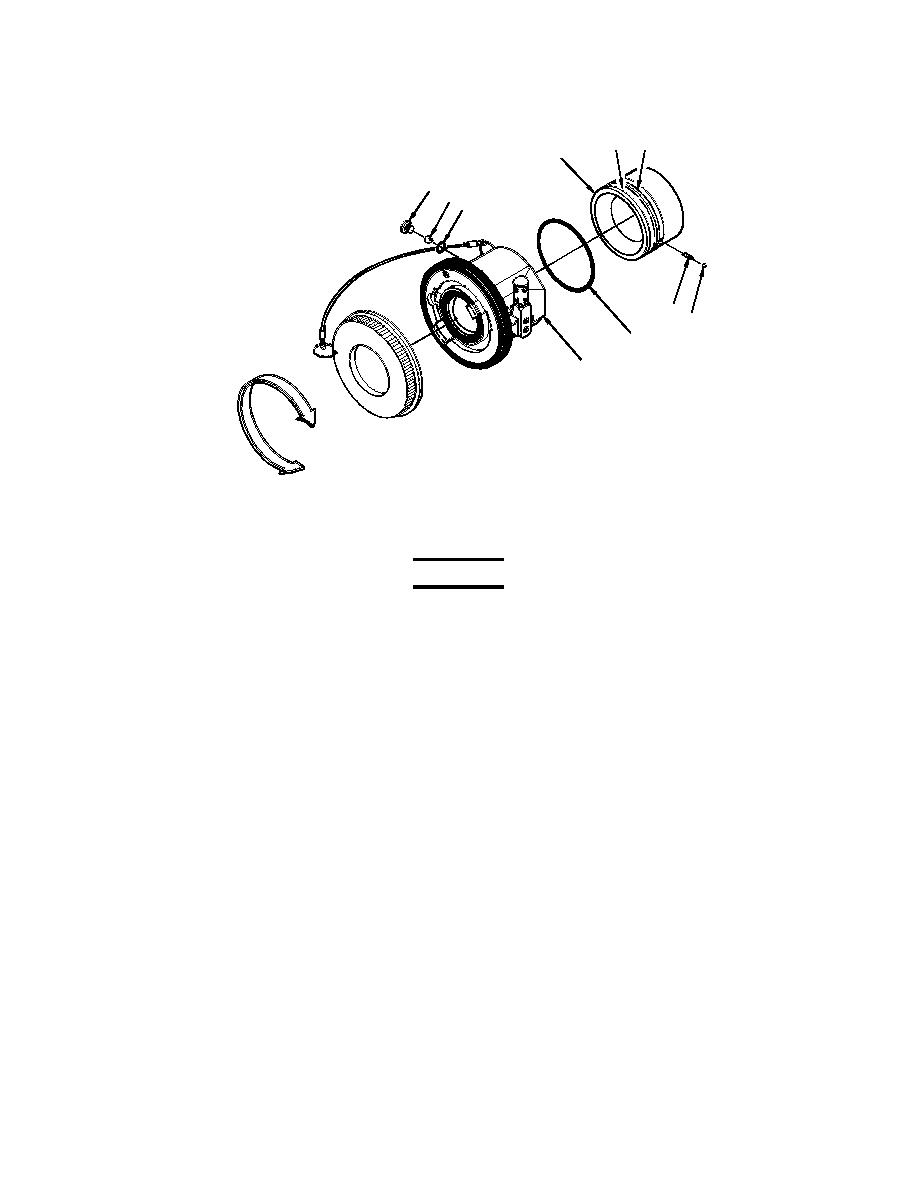

10

9

5

1

4

2

7

6

8

3

INSTALLATION

WARNING

Rubber gloves should be worn when handling fueling system components due to the

toxic effects of some fuel additives.

NOTE

When inserting balls in unisex coupling ball race, use caution to avoid dropping loose

balls. Recommend working over a wiping rag.

1.

Lightly lubricate inlet O-ring (8) with petrolatum and install in second (square) groove (9) of inlet (5).

NOTE

Due to the possibility of losing the continuity ball and spring, the following step is best

performed inside a container (e.g., a box) if possible.

2.

Start the unisex coupling (3) onto the inlet (5). Install continuity spring (7) and ball (6) into hole in inlet (5) and hold in

the compressed position while completing installation of unisex coupling (3) onto inlet (5).

3.

Place a wiping rag beneath the unisex coupling (3). Adjust coupling position until screw hole is facing up and ball race

(rounded groove) (10) in inlet is centered under screw hole. Insert the 41 balls (4) one at a time into the hole in the

housing by rotating the unisex coupling (3) back and forth while installing the balls (4). Once all 41 balls (4) are

installed, assemble O-ring (2) onto ball retaining screw (1) and install the assembly into the threaded hole to retain the

joint. Tighten retaining screw (1).

END OF WORK PACKAGE

0028 00-2