TM55-1500-345-23

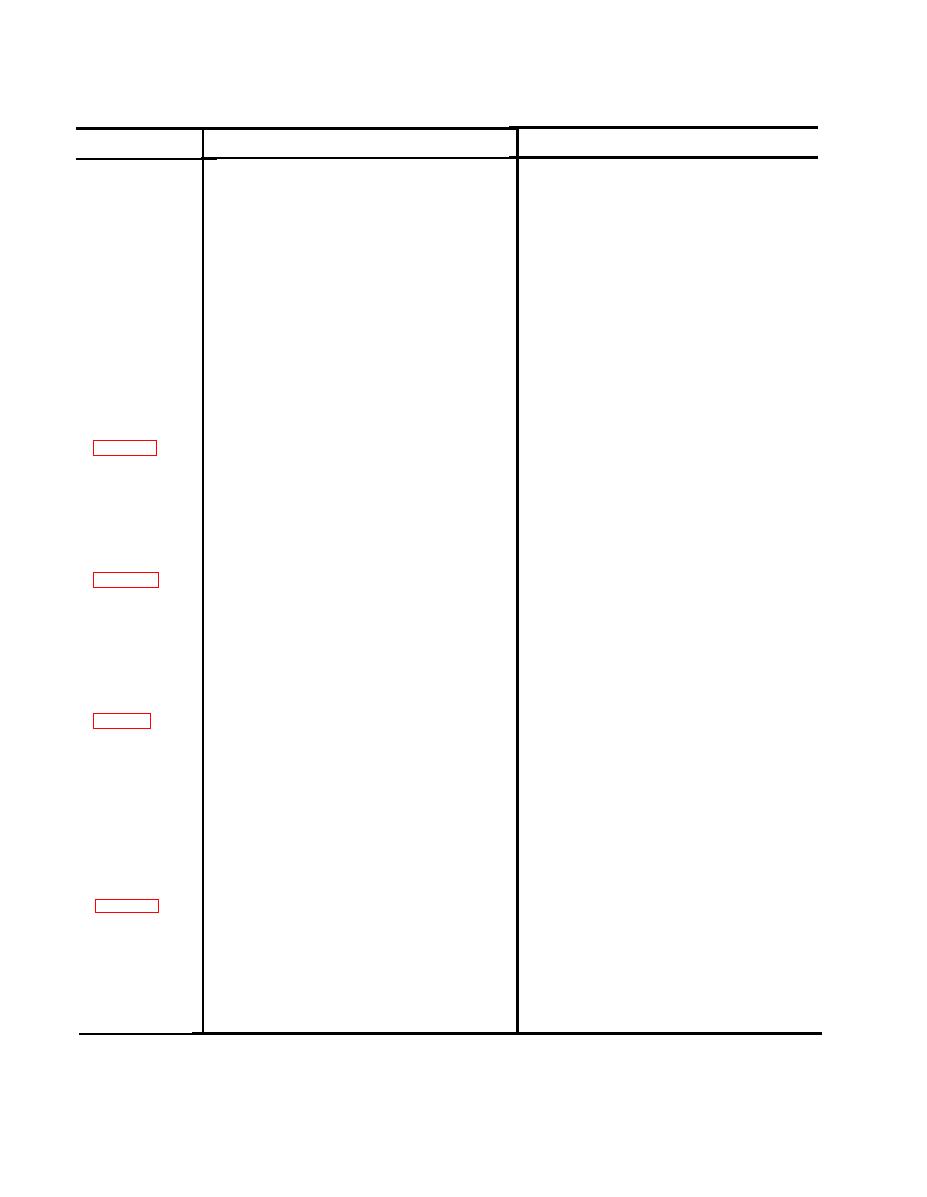

Table 3-1. Manual Spray Coating Troubles. Possible Causes, and Remedies (Continued)

PREVENTIVE MEASURES OR REMEDIES

POSSIBLE CAUSES

TROUBLE

Employ initial wipedown. using safety solvent

Insufficient drying time on wash primer and/or

Failure of wet tape

followed by thinner as an auxiliary cleaner. Rinse

epoxy primer: Insufficiently cleaned surface:

test

with clear clean water when enzymatic cleaner iS

cleaning compound residue. etc. Oil seepage

used: remove all shop primers to provide a clean

throughout inspection doors and blind rivets

surface prior to any coating: primer shop coat

(especially jet aircraft) entrapped oils and soil in

elirnination preferred as 011 removal from shop

epoxy shop primer: excessively aged primer:

primer coats practically Impossible. employ sol

insufficient removal of shop primer and/or pre-

vent-dampened cloths in Iieu of dry cloths for

removal of oil contamination. Allow aircraft to

ing wax ingredients: use of laundered rags

stand for a sufficient time to permit drainage of

instead of new mill ends: use of water-sensitive

effluent before final cleaning note the type of fail-

primer not conforming to specification

ure. such as to bare metal or intercoat failure. and

requirements: seepage of water containing

select the applicable cause and remedy accord-

cleaning compound residues from between fray-

ingly.

ing surfaces.

Allow coal to dry before recoating. (Applica-

1.

1.

Absorption of solvents by previous partially

Lifting

ble only to single component paint.)

dried film.

2.

Begin with properly prepared surface

2.

Second coats apt 10 lift if poorly prepared

surface.

Use compatible coatings and thinners

3.

1.

Drain Iines periodically.

Rust under surface.

1.

Pitting or cupping

2.

Use proper thinner proportions.

2.

Oil or grease on surface.

Strip and clean: or sand down and repaint

3.

Moisture in lines.

3.

Trapped solvents.

4.

Do not mix materials and/or compo-

NOTE

nents of different manufacturers.

1.

Use least amount of air pressure necessary

Too high air pressure.

1.

Excessive spray fog

Release trigger when gun passes target.

2.

2.

Spraying past surface of the product.

Ascertain and use correct setup

3.

Wrong air cap or fluid tip.

3.

4.

Stroke the gun 6 to 10 inches from surface

4.

Gun stroked too far from the surface.

Add the correct amount of solvent by meas-

5.

Material thinned too much.

5.

sure or test.

1.

Laboratory analysis to verify acceptability of

1.

Unsatisfactory wash primer or primer.

Sandpaper finish

the material: check wash primer and primer

application procedures.

Provide cleaner painting areas.

2.

2.

Excessive dirt contamination from painting

area.

Scuff-sand wash primer using No 320 and

3.

Insufficient scuff-sanding of wash primer or

3.

wet-or-dry abrasive. paper P-C-451.

primer.

Flush paint lines frequently with solvent.

4.

4.

Improperly cleaned paint lines.

3-22