4. Check No. 3 Part Power Trim.

a.

Introduction. Prior to trimming, engine must be

brought up to its part power trim output and allowed to

run approximately five minutes to bring the engine to

normal operating temperatures.

b.

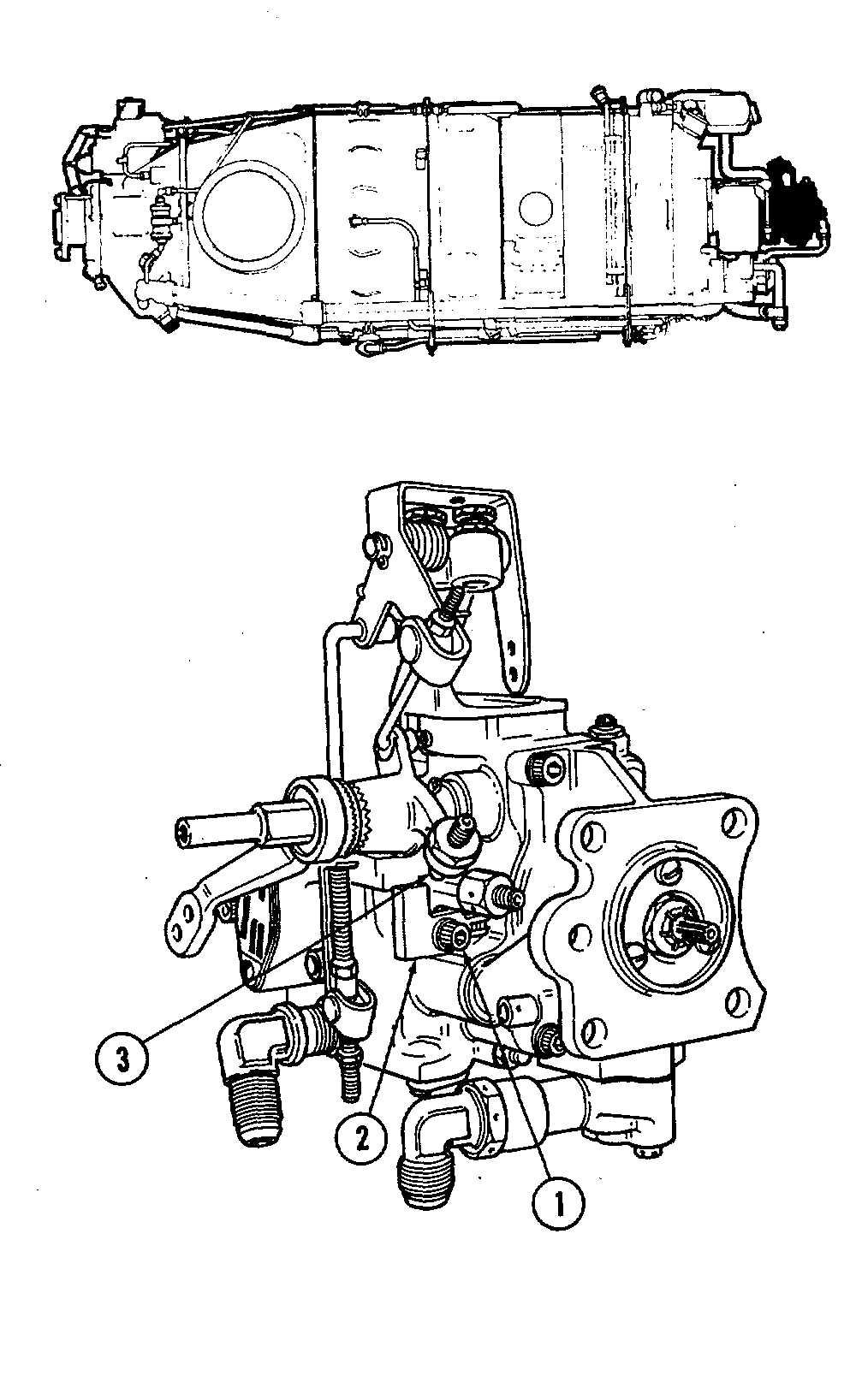

Part Power Trim Stop. Fuel control units are

calibrated during bench test to insure maximum flow is

obtained. The trim stop must be adjusted to individual

engines on installation to insure maximum power on a

71°F (21°C) day. If engine inlet temperature is other

than this, it would not be possible to set the maximum

speed stop without first reaching either an interturbine

temperature or a torque limit. To overcome this, a part

power trim stop is provided. The stop is a movable

spacer placed between gas generator maximum speed

(Ng) stop and power lever anvil, and represents a 1700

rpm (Ng) speed drop. This stop is permanently attached

to the fuel control unit and is moved from the stowed

position for engine trimming.

(1)

Loosen screw (1) securing part power trim

stop (2) to gas generator maximum speed stop anvil.

(2)

Position part power trim stop so that it is

between power lever anvil and maximum gas generator

speed stop (3).

(3)

Tighten screw (1).

GO TO NEXT PAGE

1-142