TM55-2840-251-23

Section III PRINCIPLES OF OPERATION (Continued)

1-15 AIR SYSTEM

Pressure air is used to seal the bearing compartments

and to cool internal parts of the engine.

Compressor discharge pressure (P3) is directed to the

fuel control unit to provide a signal indicating change of

condition within the engine.

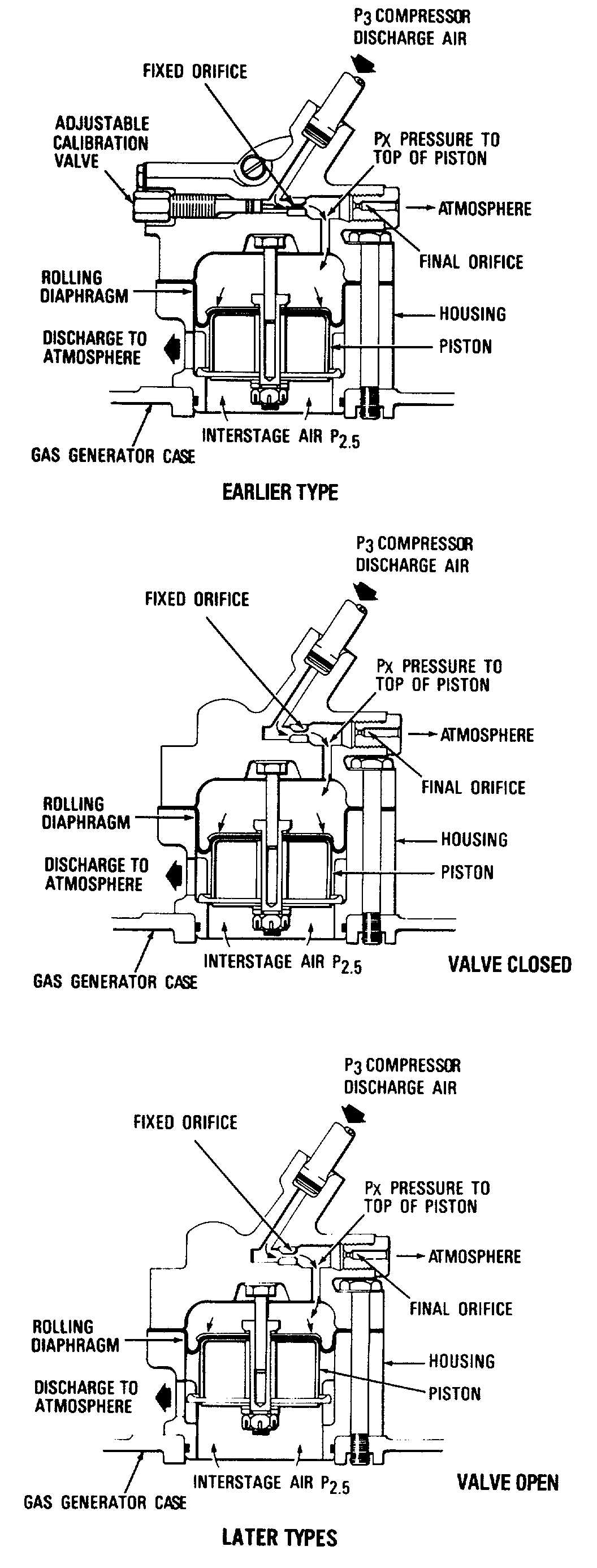

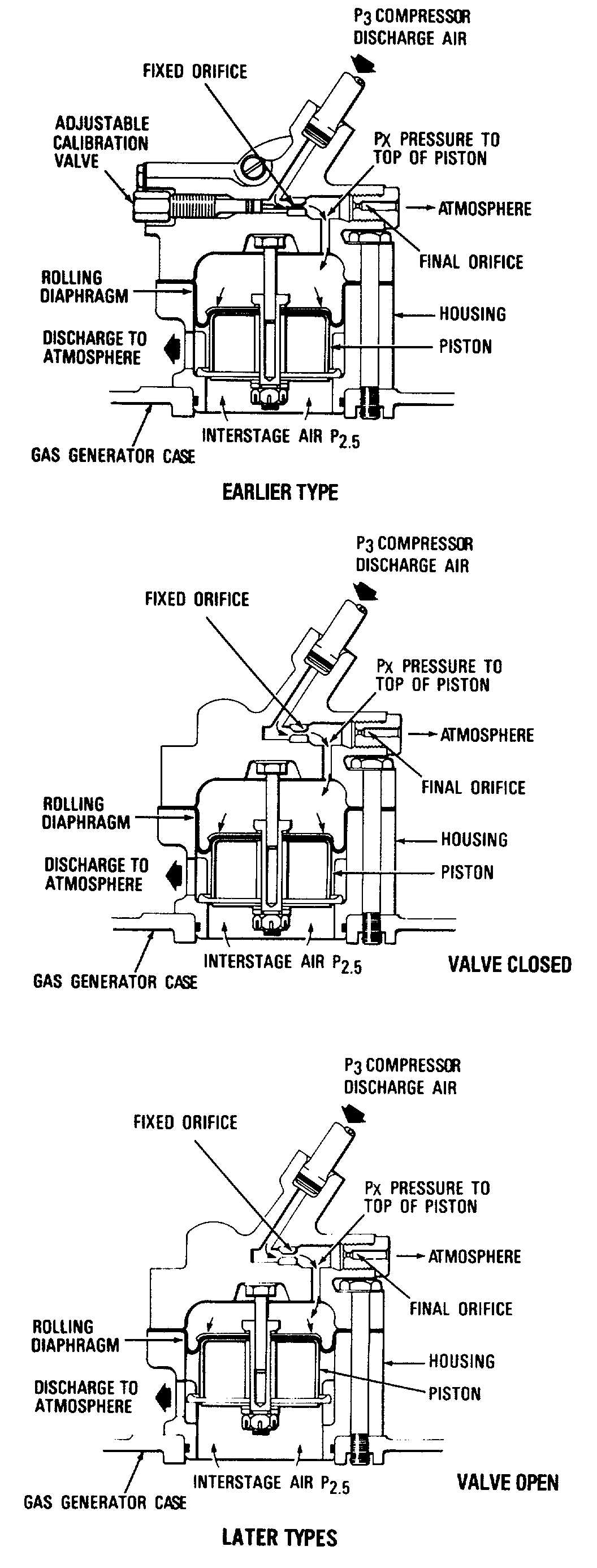

Compressor stall is prevented by the compressor bleed

valve. The bleed valve consists of a piston and rolling

diaphragm operating within a housing under opposing

pressures. The bleed valve is secured by two bolts to

an outlet port on the gas generator case which provides

a direct passage for the flow of compressor interstage

air (P2.5) to the bottom of the valve. Compressor

discharge air (P3) is tapped off and metered through an

orifice (adjustable in earlier engines and fixed in later

engines) in the cover of the unit, then passed through an

intermediate passage and out to atmosphere through

another orifice. The control pressure (Px) between the

two orifices acts upon the upper side of the piston, so

that when Px is greater than P2.5 the bleed valve

closes.

END OF SECTION

1-20