TM 1-1500-204-23-1

(b)

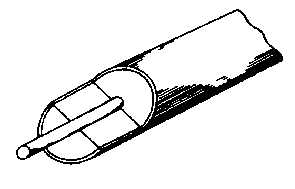

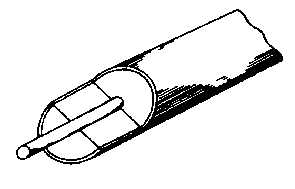

Fenwal system. The Fenwal

system, as shown in figure 9-34, uses a single wire

surrounded by a continuous string of ceramic beads in an

Inconel tube. The beads in the Fenwal detector are

wetted with a eutectic salt which possesses the

characteristic of suddenly lowering its electrical resistance

as the sensing element reaches its alarm temperature.

c.

Maintenance of Fire Detection Systems. Inspect

fire detection systems for the following:

•

Cracked or broken sections caused by crushing

or squeezing between inspection plates, cow

panels, or engine components.

•

Abrasion caused by rubbing of element on

cowling, accessories, or structural members

•

Pieces of safety wire or other metal particles

which may short the spot detector terminals.

•

Condition of rubber grommets in mounting

clamps, which may be softened from exposure

to oils, or hardened from excessive heat

•

Dents and kinks In sensing element sections

Figure 9-34. Fenwal Sensing Element

NOTE

Limits on the element diameter,

acceptable

dents

or

kinks,

and

degree of smoothness of tubing

contour

are

specified

by

manufacturers. No attempt should

be made to straighten any acceptable

dent or kink, since stresses may be

set up that could cause tubing

failure.

•

Loose nuts or broken safety wire at the end of

the sensing elements

NOTE

Loose nuts should be re-torqued to

the

value

specified

in

the

manufacturer's instructions. Some

types

of

sensing

element

connections

require

the

use

of

copper

crush

gaskets.

These

gaskets should be replaced any time

a connection is separated

•

Broken or frayed flexible leads, if used.

NOTE

The flexible leads is made up of

many fine metal strands woven into a

protective covering surrounding the

inner insulated wire. Continuous

bending of the cable or rough

treatment can break these fine wires,

especially those near the connectors

Broken strands can also protrude

into the insulated gasket and short

the center electrode.

•

Proper sensing element routing and clamping.

NOTE

Long unsupported sections may

permit excessive vibration which can

cause

breakage.

The

distance

between clamps on straight runs is

usually about 8 to 10 inches, and is

specified by each manufacturer. At

end connectors, the first support

clamp is usually located about 4 to 6

inches from the end connector

fittings. In most cases, a straight run

of 1 inches is maintained from all

connectors before a bend is started,

and an optimum bend radius of 3

inches is normally adhered to

9-35