TM 1-1500-204-23-1

c.

Sudden Reduction in Engine RPM. When the

propeller or rotor strikes a small object which results in a

sudden reduction In engine rpm, the engine shall be

thoroughly checked using the following procedures:

(1)

Make a thorough external examination of

engine crankcase and nose section to determine

whether any parts have been damaged. When damage

is found which cannot be corrected by line maintenance,

remove engine.

(2)

Remove magnetic sump plugs, If present,

and engine oil screens or filters. Examine for presence

of metal particles.

(3)

Remove engine sump plugs, drain oil into

a clean container, strain through a clean cloth, and

examine cloth and strained oil for metal particles.

NOTE

· Metal particles found In the sumps or

In oil screens or filters will not be

considered the results of an Internal

failure caused by sudden stoppage,

since the screens or filters are

located at the oil inlet to the engine.

Sudden stoppage, therefore, will not

permit circulation of the oil to the

extent that metal particles would be

deposited on the screens or filters.

· When heavy metal particles are

found In the oil, It indicates a definite

engine failure, and engine must be

removed. However, when metal

particles present are similar to fine

filings,

continue

examination

of

engine to determine its serviceability.

(4)

Remove

propeller

and

examine

crankshaft, or propeller drive shaft on reduction-gear

engines, for misalignment.

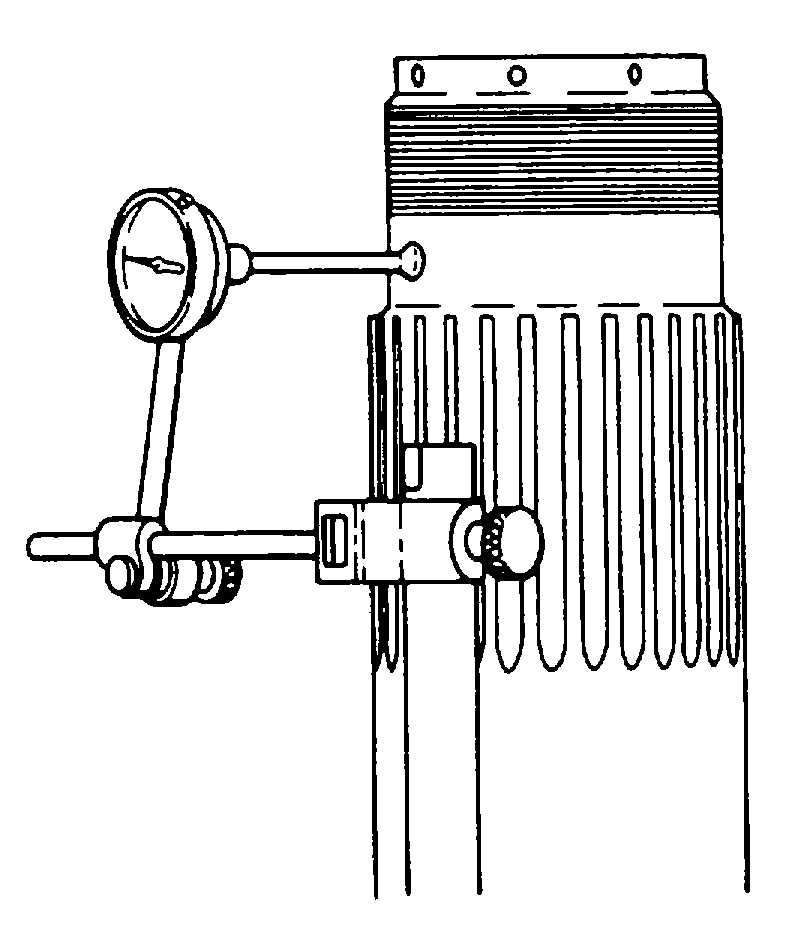

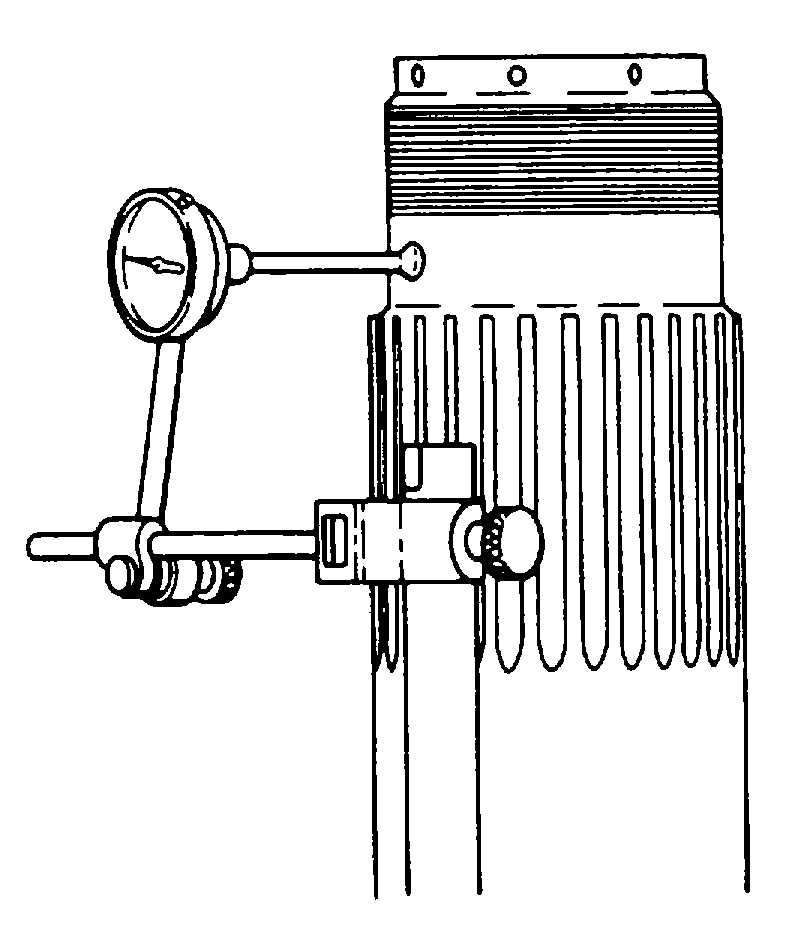

(5)

Clamp a test indicator to nose section of

engine and remove front or outside spark plugs from all

cylinders on radial engines and top spark plugs on all

opposed engines.

(6)

Turn crankshaft and observe if crankshaft

or propeller shaft runs out at either front or rear propeller

cone seat location, as shown In figure 7-21.

NOTE

· When there is runout of more than

0.015 inch full indicator reading of

crankshaft or propeller drive shaft at

front cone seat location, remove

engine. Even though runout of

crankshaft or propeller drive shaft at

front cone seat is less than 0 015

inch full indicator reading, examine

rear cone seat location.

· When any runout is found at rear

cone seat location, which Is not In

same plane as runout at front cone

seat location, remove engine.

· When crankshaft or propeller drive

shaft runout does not exceed these

limits, install serviceable propeller

and make an additional check by

tracking propeller at tip in same

plane

perpendicular

to

axis

of

rotation to assure that blade track

tolerance Is within limits.

(7)

Start engine and examine for smooth

operation and adequate power output. When engine

operates properly during this ground check, shut engine

off and again examine oil system for metal particles.

Figure 7-21. Checking Propeller Shaft Runout

7-24