TM 1-1500-204-23-1

4

Depress and hold timing plunger on

magneto, while continuing rotation of engine, until timing

plunger is fully engaged.

5

See that timing indicator shows

correct degree of advanced timing.

(2)

Ignition

harness.

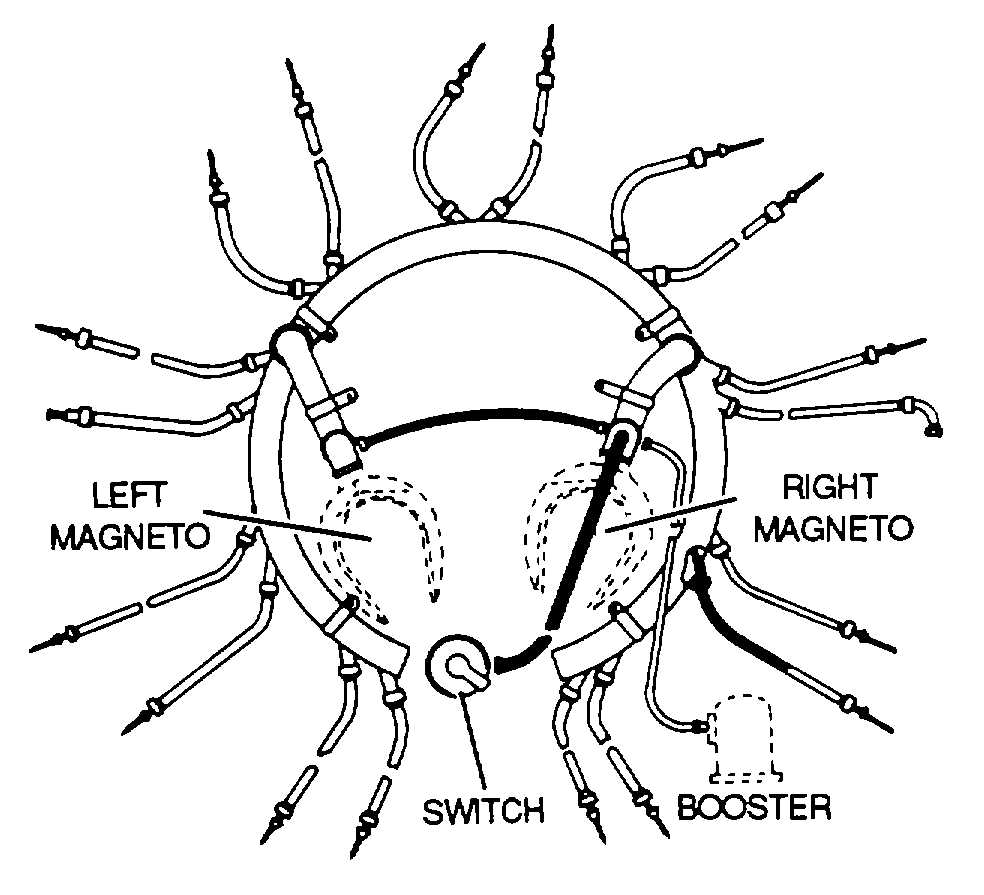

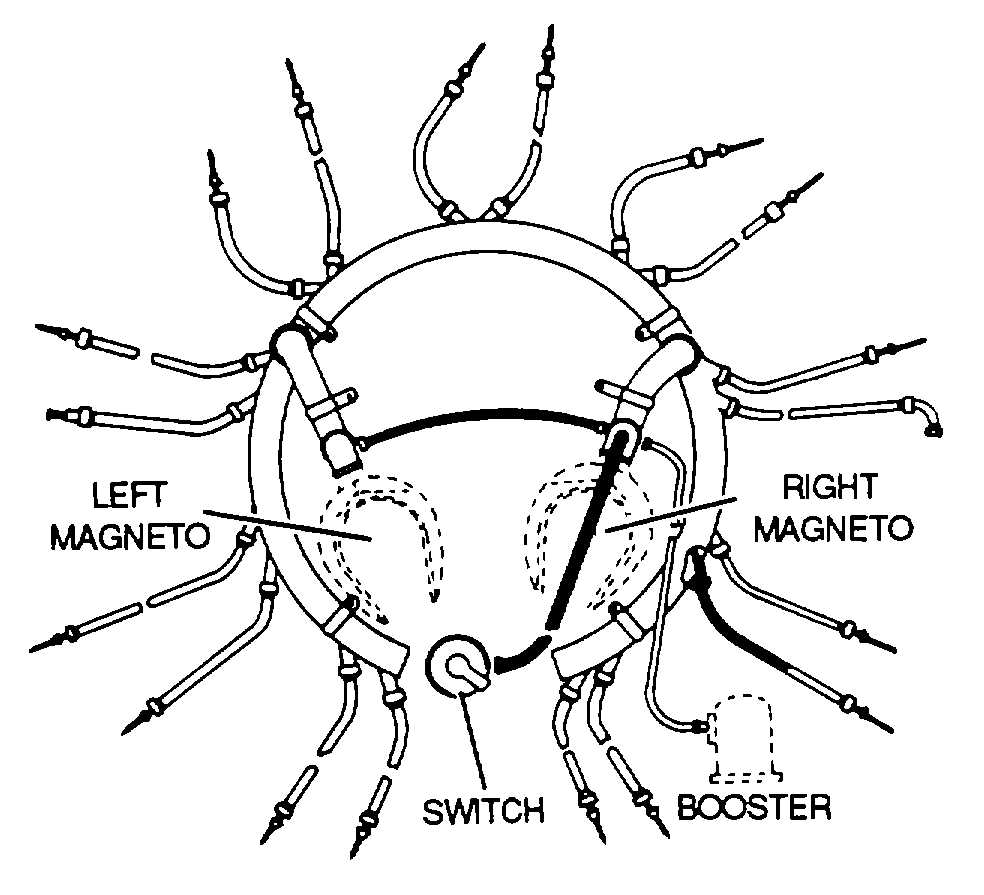

The

ignition

harness, as shown in figure 7-18, contains an insulated

wire for each cylinder that the magneto serves In the

engine. One end of each wire Is connected to the

distributor block and the other end is connected to the

proper spark plug. The Ignition harness serves a dual

purpose. It supports the wires and protects them from

damage by engine heat, vibration, or weather. It also

serves as a conductor for stray magnetic fields that

surround the wires as they momentarily carry high-voltage

current. By conducting these magnetic lines of force to

the ground, the ignition harness cuts down electrical

interference with the aircraft radio and other electrically

sensitive equipment. When the radio and other electrical

equipment are protected in this manner, the ignition

harness wiring is said to be a shield. Without this

shielding, radio communication would become virtually

impossible. The ignition harness check consists of a

visual and an electrical check using the following

procedures.

(a)

Examine

all

accessible

parts

of

distributors, harnesses, and leads for chafing, broken

insulators,

corrosion,

moisture,

damaged

or

dirty

terminals, and security of mounting at the time specified

in the applicable maintenance manual.

Figure 7-18. Ignition Harness

(b)

Repair or replace defective parts as

necessary. Keep all parts clean and free of foreign

matter.

NOTE

The high-tension system manifold Is

never taken apart in the field, as this

will destroy the elastic gel seal.

1

Clean dirt and grease from harness

by wiping with a clean, dry cloth.

2

Clean

terminals

with

acetone,

Federal Specification O-A-51.

NOTE

Replace ignition harness leads when

more than three wire strands are

broken in one inch of harness length

or if Insulation is damaged

(c)

Perform a high-voltage breakdown

test when an ignition malfunction occurs and after cable

replacement in rewireable harness or leads. Use an

approved high-voltage tester, and test for serviceability as

follows.

1

Remove all leads from spark plugs.

2

Remove

spark

plug

elbow

assembly from ignition lead.

3

Examine

lead

insulation

for

evidence of chafing, breaks, or holes. Replace parts as

required.

4

Ground all leads, except one for

number 1 cylinder, to engine.

5

Connect ground lead of tester to

engine, and connect high-tension lead to number 1

cylinder lead.

6

Test

and

record

any

leakage

detected.

7

Test remaining leads.

8

When

two

leads

from

same

distributor show leakage, remove ground from both leads

and repeat test. When leakage is stopped by removing

ground from other lead, leakage is probably between.

7-19