TM 1-1500-204-23-2

(5)

Electrical tools must be connected to a low resistance ground

3-2.

Maintenance of Shop Equipment. Maintenance of shop equipment consists of cleaning, preventive

maintenance, and replacement of defective parts. Preventive maintenance includes before-operation, during-operation,

after-operation services performed by operator, and scheduled services to be performed at designated intervals. Consult

the operation and service instructions manual for specific maintenance instructions on particular types of equipment.

a.

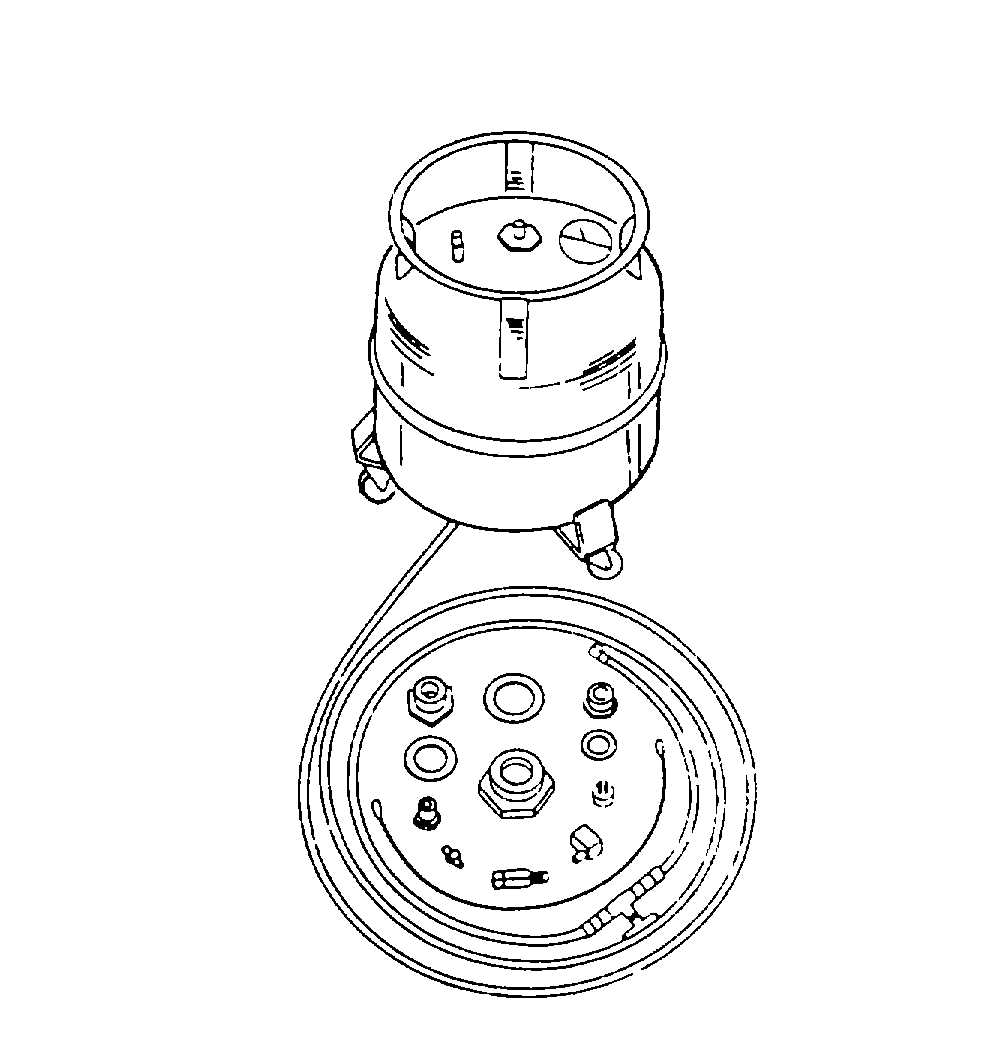

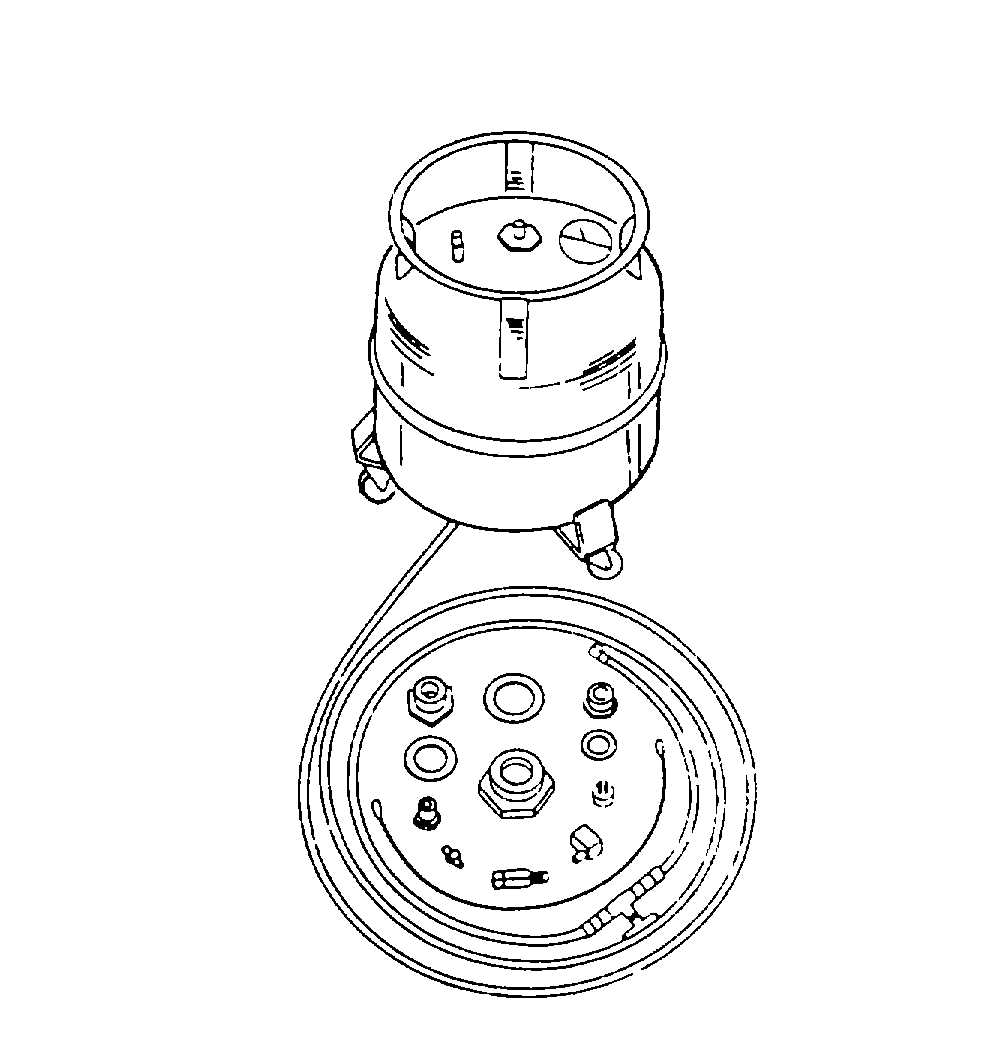

Hydraulic Filler and Bleeder Unit. The hydraulic filler and bleeder shown in figure 3-1 is used for servicing

and bleeding aircraft hydraulic systems and associated hydraulic equipment. The unit consists of a hydraulic fluid

storage tank with an air pressure indicator, air filler and fluid filler valve, and a servicing hose and valve. The following

are general instructions for maintenance and service.

WARNING

Do not attempt to service or perform maintenance on filler and bleeder unit until all air pressure has been

released. Failure to comply can result in damage to equipment or personnel.

Do not use any filler and bleeder unit unless it is equipped with a safety relief valve to bleed off excessive

air pressure. Failure to comply can result In injury or death.

Drycleaning solvent Is flammable and solvent vapors are toxic. Use P-D-680, Type II Solvent in a well-

ventilated area. Keep away from open flames. Avoid prolonged solvent contact with skin.

(1)

Clean reservoir and fittings with a cloth moistened in drycleaning solvent, Federal Specification P-D-

680, and wipe dry with a clean cloth.

Figure 3-1. Typical Hydraulic System Filler and Bleeder

NOTE

Calibration of hydraulic gauges is accomplished in the instrument shop which is equipped with hydraulic

Instruments Oil preservatives, MIL-H-6083, will be utilized at time of overhaul during depot maintenance

as a calibrating medium in lieu of test fluid, MIL-H-5606 Recalibration of flow indicators on test stands will

be required if the fluid for which the equipment is calibrated does not conform to the requirements of oil

preservatives, MIL-H-6083.

(2)

Remove corrosion, where paint has chipped, by scouring with crocus cloth, Federal Specification P-C-

458

3-3