TM 1-1500-204-23-2

(h)

Prior to first use of test stand, examine pressure gauge to determine that maximum hydraulic

pressure is obtainable, and Inspect for high pressure leaks.

(2)

Periodic inspection. For frequency and scope of periodic inspection, consult the operation and service

instructions manual for the specific test stand; however, the following will be used as a general guide.

(a)

Visually inspect interior of hydraulic reservoir for possible accumulation of sludge. Inspect and

replace reservoir vent filter when necessary.

(b)

Examine tire treads on trailer assembly for uneven wear. Rotate tires when necessary

(c)

Carefully inspect housing and cabinet assembly for loose screws, bolts, and nuts. Tighten as

required.

(d)

Inspect fuel system for loose fittings that may cause fuel leakage. Examine and replace fuel

filter as necessary.

(e)

Examine oil level in engine crankcase and gearbox transmission, and add oil as required.

Replace engine oil filter. Examine oil-bath type air cleaner and service as necessary.

(f)

Remove and examine spark plugs, and clean with spark plug cleaner. Discard all unserviceable

spark plugs.

(g)

Inspect battery cell electrolyte with a hydrometer. A specific gravity reading of 1.150 or less

indicates a low battery charge.

NOTE

When test stand is out of operation for lengthy, intermittent periods, batteries should be tested more

frequently, or placed on trickle charge in battery charge.

(h)

Examine engine ignition timing, magneto point condition, and gap.

(3)

Lubrication. Consult applicable operation and service instructions manual of particular hydraulic test

stand for type of lubricant, time of application, amount and point of lubrication.

d.

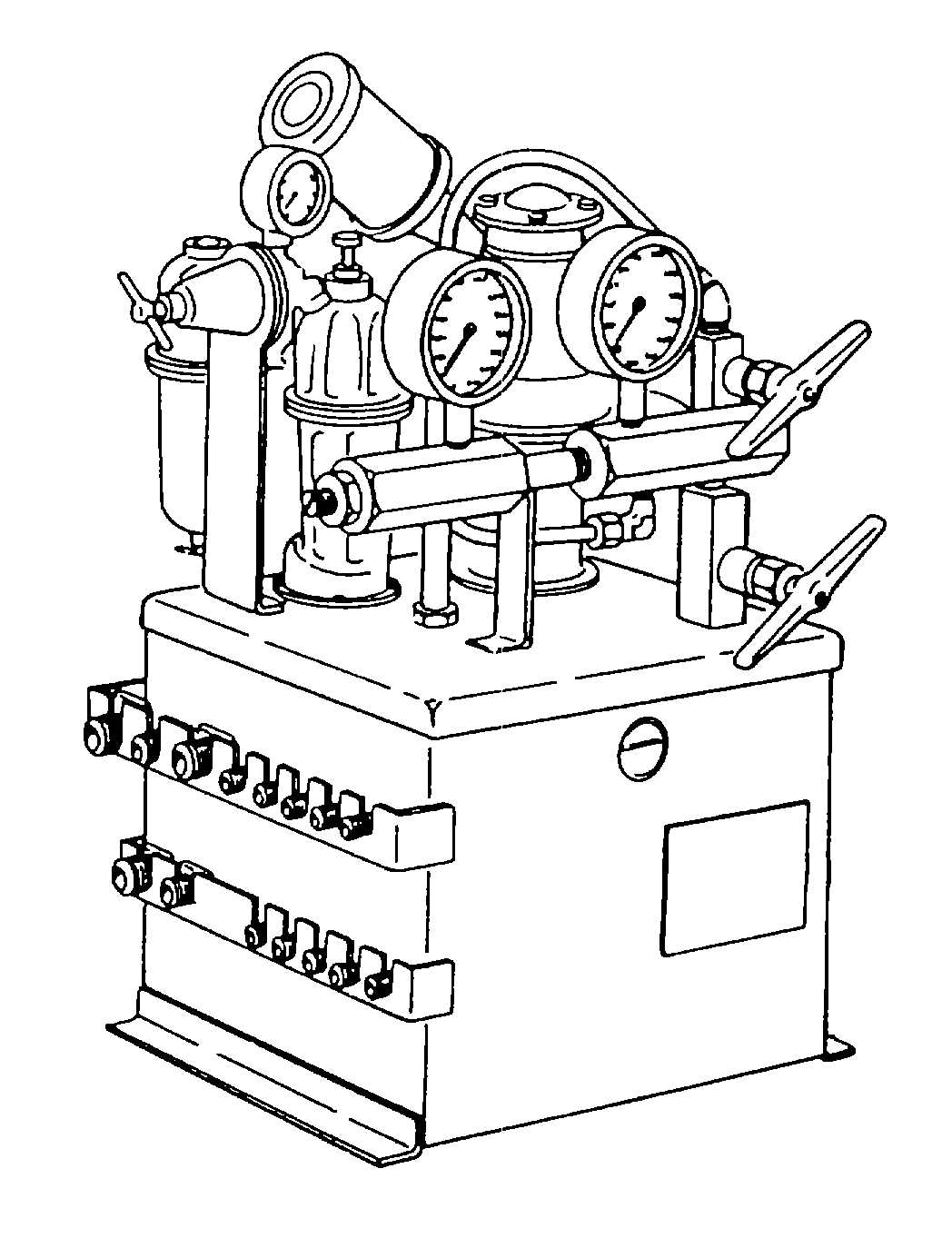

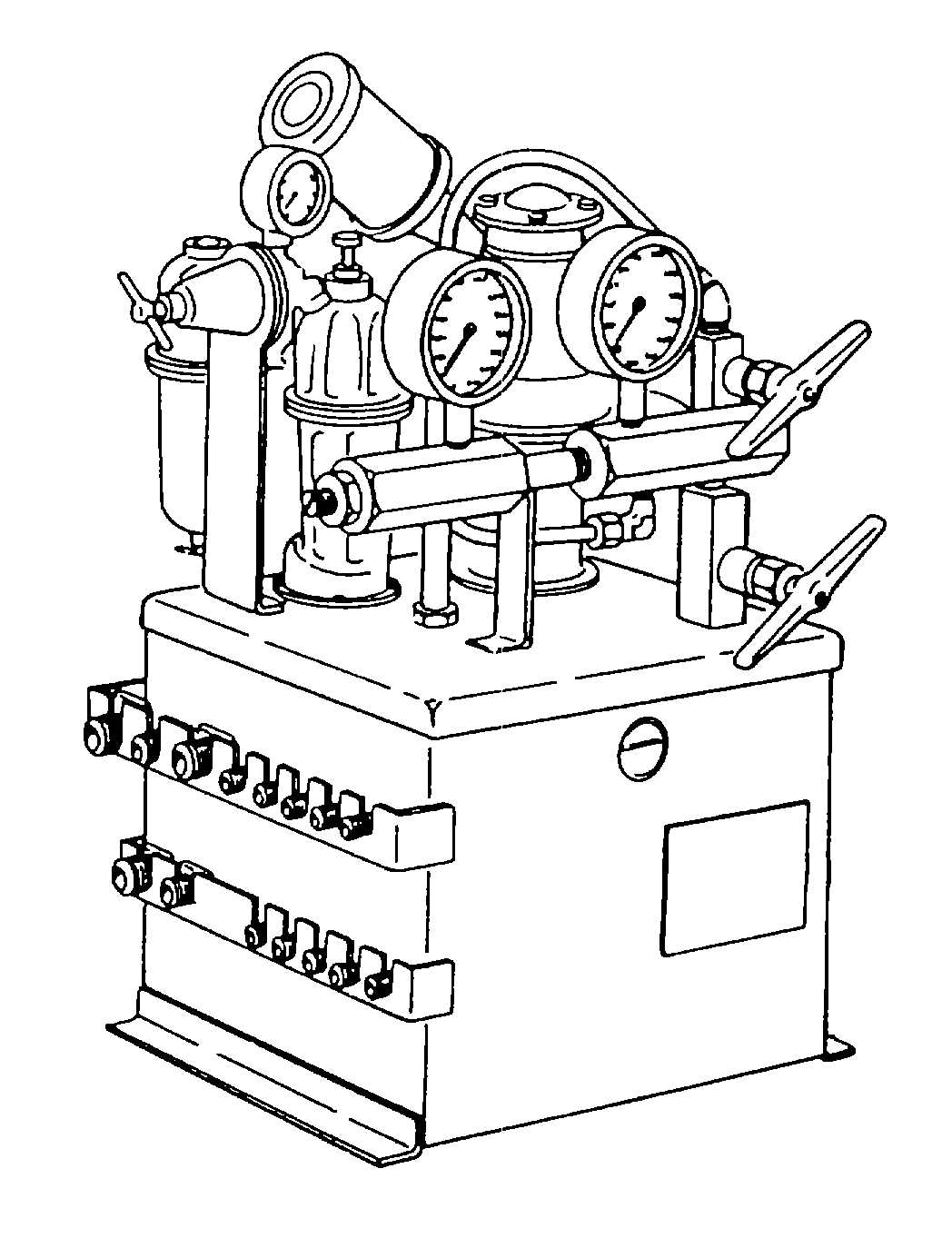

Hydraulic Hose Testing Unit. The hose testing units commonly used are designed to provide hydraulic

pressure to 15,000 psi for proof pressure and leakage tests on aircraft hose assemblies. See figure 3-3 for a typical unit.

Prior to use the operator should:

(1)

Examine fluid level in the reservoir. Add hydraulic fluid, MIL-H-6083, as required.

(2)

Inspect entire unit for loose connections, defective lines, or fittings. Tighten or replace as required.

Figure 3-3. Typical Hydraulic Hose Testing Unit

3-6