TM 1-1500-204-23-2

4

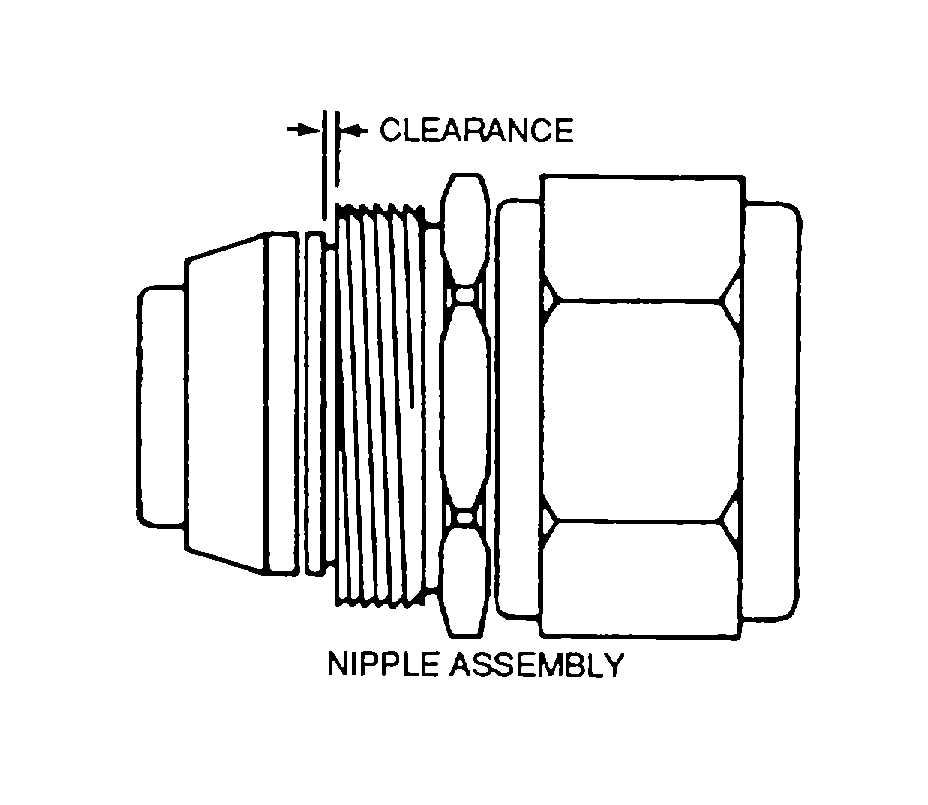

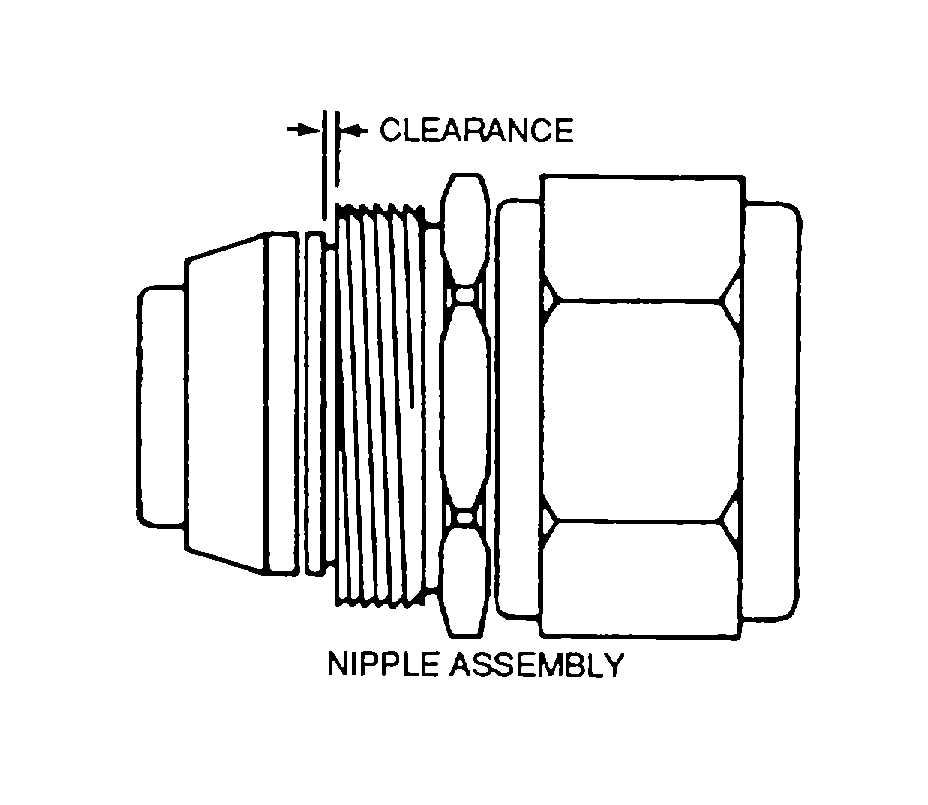

Test for overtorquing by placing a new sleeve insert of proper size and type for the nipple

assembly on the nipple in the normal assembled position. Check for clearance between the sleeve and nipple faces

(figure 4-47). Clearance shall exist for good nipple assemblies.

5

Visually inspect wrench flats on forgedtype elbow nipple assemblies for excessive damage.

(e)

Socket. The socket will be Inspected for the following defects:

1

Visually inspect for distortion or egg-ing and test for damaged threads by threading a new

nipple assembly of proper size into the socket threads.

2

Visually inspect for stress cracks. (Usually appear as longitudinal.)

(f)

Sleeve. The sleeve will be inspected for the following defects.

1

Check for out-of-roundness.

2

Check sealing surface for warpage and damage to mating surface.

(9)

Cleaning. Clean and degrease hose assemblies and component parts before inspection.

WARNING

Drycleaning solvent is flammable and solvent vapors are toxic. Use P-D-680, Type II Solvent in a well-

ventilated area. Keep away from open flames. Avoid prolonged solvent contact with skin.

(a)

Cleaning fluids. Any of the following cleaning fluids or other acceptable commercial degreasing

solvents may be used for cleaning Teflon hose assemblies.

FLUID

SPECIFICATION

Dry Cleaning Solvent

P-D-680

Trichloroethylene

MIL-7003

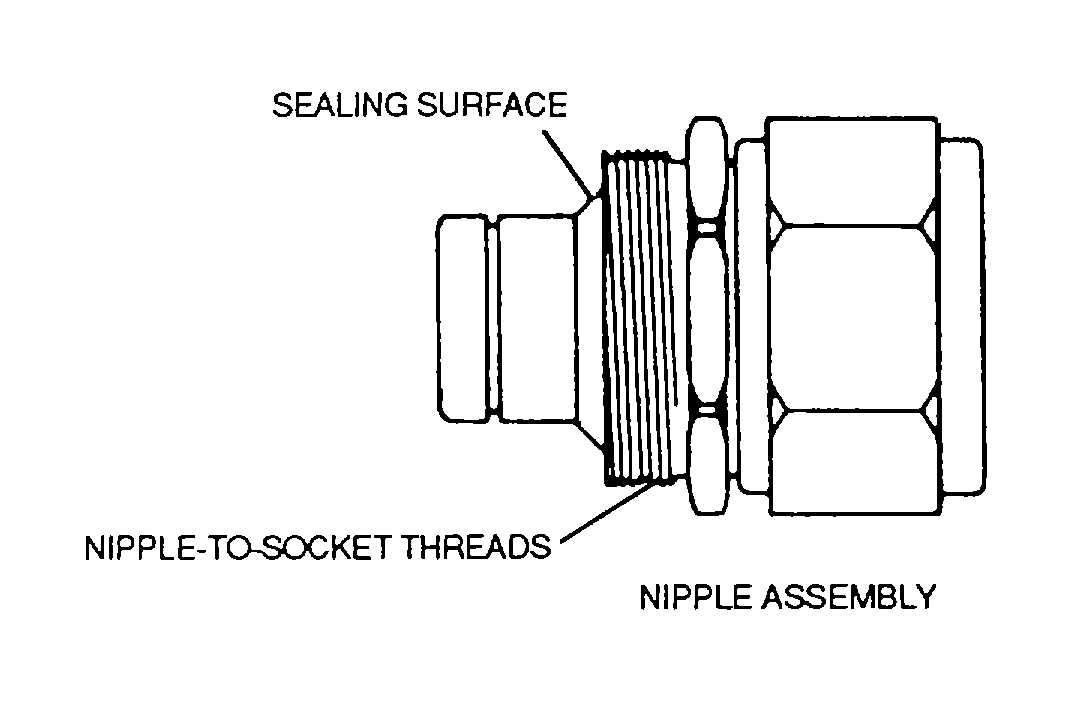

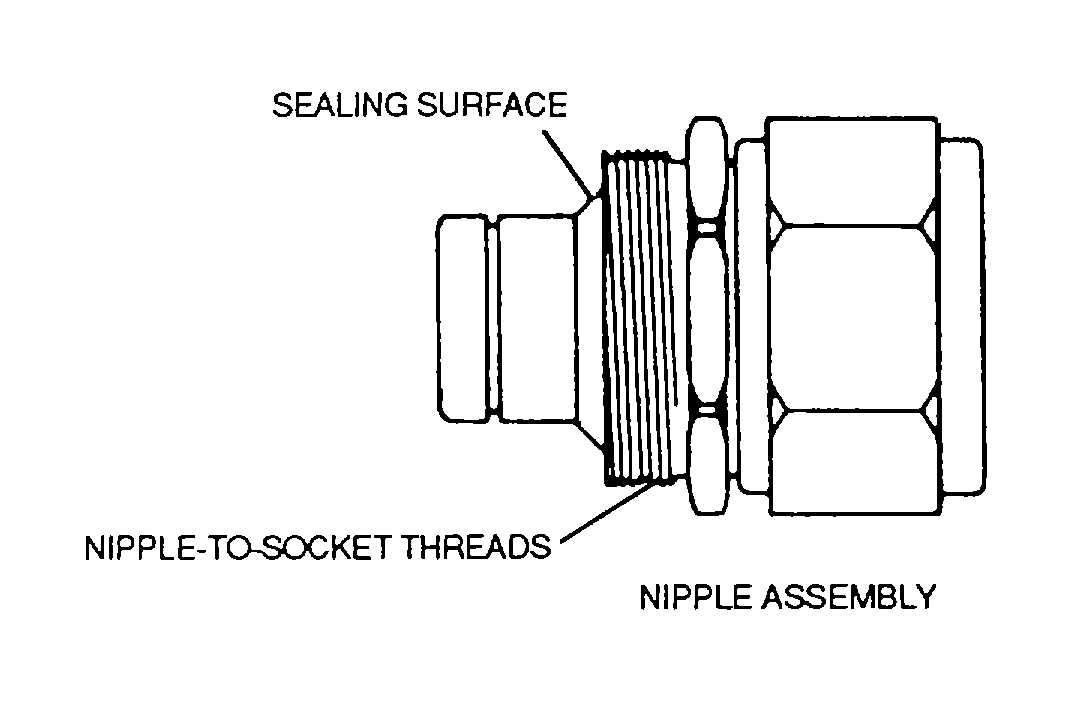

Figure 4-46. Nipple Assembly Surface

Figure 4-47. Nipple Assembly Clearance

4-59