TM 1-1500-204-23-3

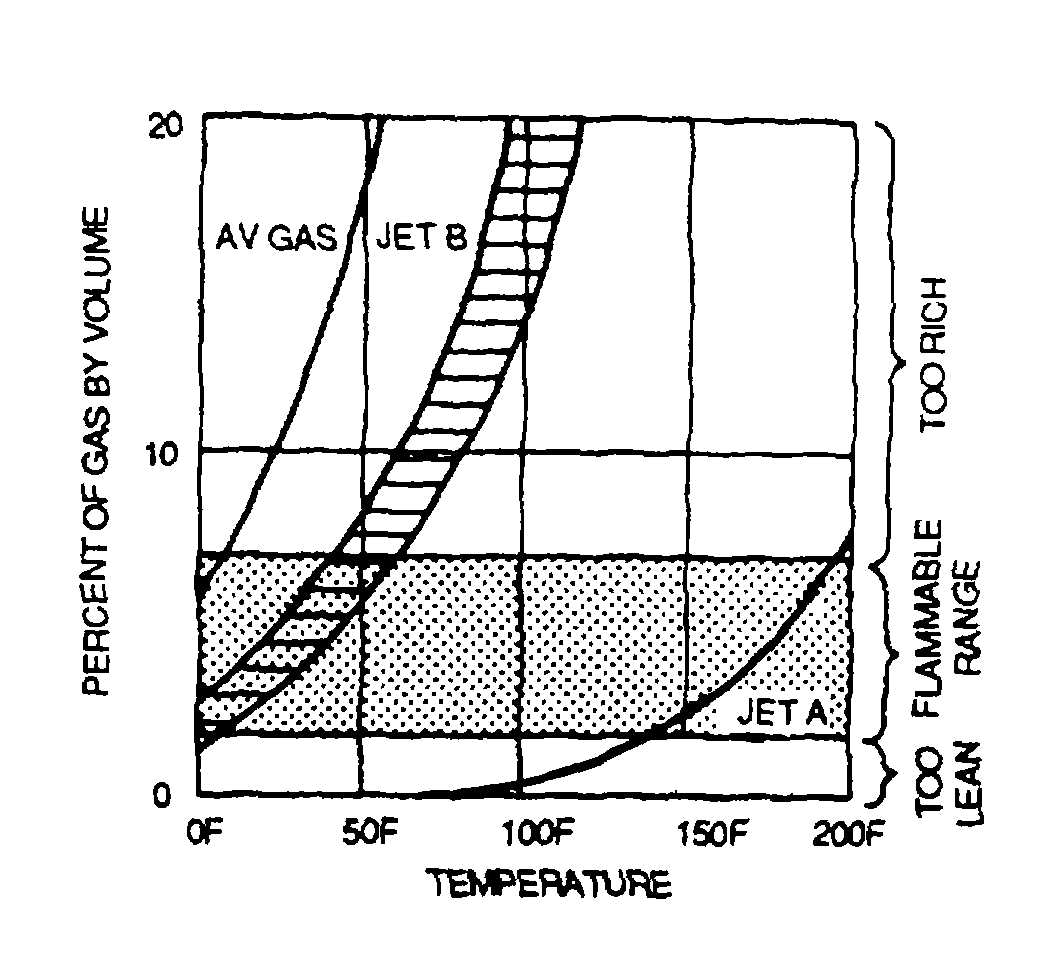

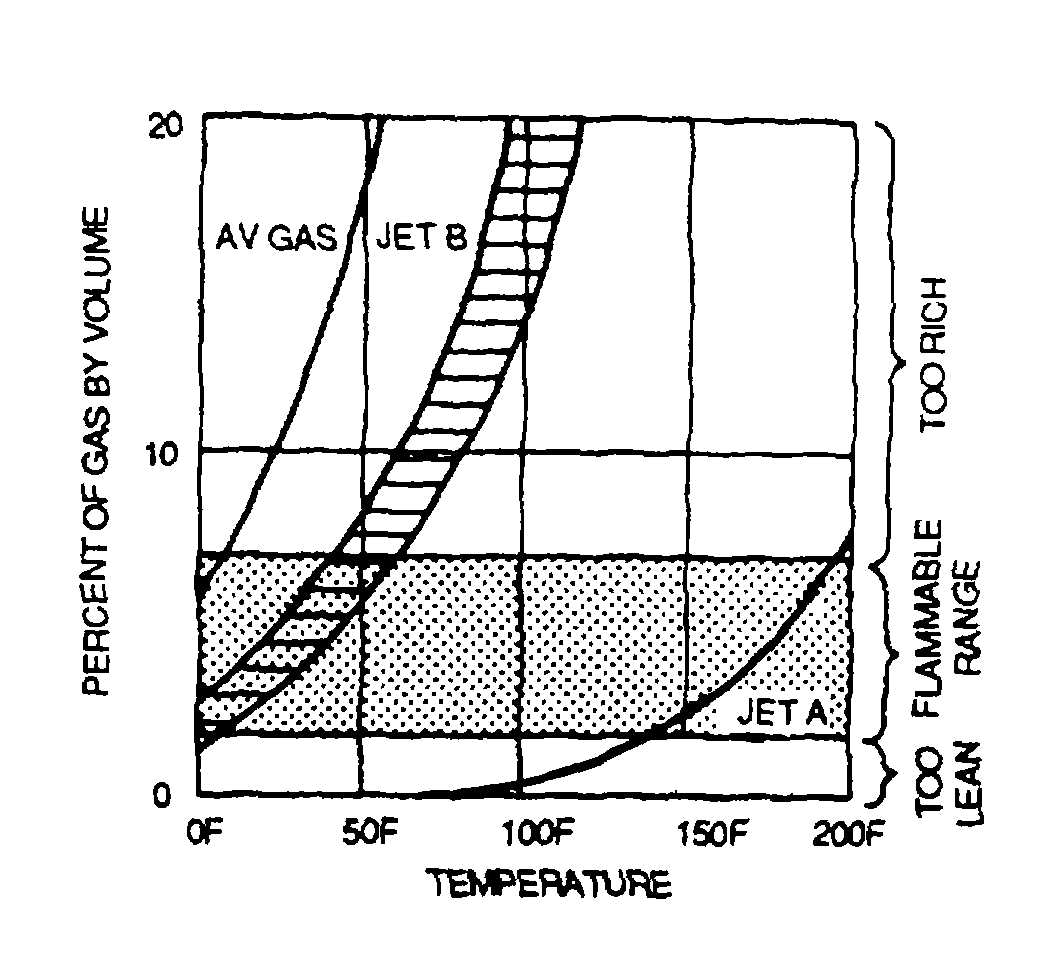

Figure 2-1. Vaporization Characteristics

Table 2-2. AVGAS Identification

Grade

Color

80/87

Red

100/130 High Lead

Green

100/130 Low Lead

Blue

115/145

Purple

2-4. Contamination of Fuels. There are several forms

of contamination in aviation fuels. The higher the

viscosity of the fuel, the greater is its ability to hold

contaminants in suspension. For this reason, jet fuels

having a high viscosity are more likely to have

contaminants. Table 2-3 shows visual contaminant

characteristics. Water, solids, and microbial growths are

the principal types of contamination.

a.

Water. Either fresh or salt water may be present

in fuel, and either may be present as dissolved or free

water.

(1),

Dissolved water. Dissolved water is water

that has been absorbed by the fuel. It cannot be seen and

cannot be separated out of the fuel by either filtration or

mechanical means. The danger of dissolved water is that

it settles out as free water when the fuel is cooled to a

temperature lower than that at which the water dissolved.

Such a cooling of fuel is likely at high altitudes. Once

freed, all the dangers of free water are present.

(2)

Free water. Free water can be removed

from fuel by adequate filtering. It can be seen in the fuel

as a cloud, an emulsion, droplets or, in large amounts, as

water on the bottom of a tank, sample container, or

filter/separator. Free water, either fresh or salty, can

freeze in the aircraft fuel system, can make certain

aircraft instruments malfunction, and can corrode the

components of the aircraft fuel system. (Salt water is

more corrosive than fresh water.) Ice in an aircraft fuel

system can make the engines fail.

b.

Solids. Sediment from tanks, pipes, hoses,

pumps, people, and the air contaminates fuel. The most

common elements of the sediment found in aviation fuels

are bits of rust, paint, metal, rubber, dust, and sand.

Sediment is classified by particle size as shown in figure

2-2.

(1)

Coarse sediment. Particles classified as

coarse are 10 microns in size or larger (25,400 microns =

1 inch). Coarse sediment settles out of fuel easily, and it

can also be removed by adequate filtering. Particles of

coarse sediment clog nozzle screens, other fine screens

throughout

the

aircraft

fuel

system

and,

most

dangerously, the fuel orifices of aircraft engines. Particles

of this size also get wedged in sliding valve clearances

and valve shoulders where they cause excessive wear in

the fuel controls and fuel-metering equipment.

(2)

Fine sediment. Particles classified as fine

are smaller than 10 microns in size. Removing fine

sediment by settling or filtering is effective only to a

limited degree; the particles can, however, be centrifuged

out in a rotating chamber. Fine sediment accumulates in

fuel controls and forms a dark shellaclike surface on the

sliding valves. It can also form a sludge-like material that

makes

fuel-metering

equipment

operate

sluggishly.

Particles of fine sediment are not visible to the naked eye,

but they do scatter light. This light-scattering property

makes them show up as point flashes of light or as a

slight haze in the fuel.

2-3