TM 1-1500-204-23-3

(j)

Fitting Damage/Finish. Fittings which have

inter-crystalline corrosion or scratches, outside of the

critical sealing surface, to a depth of .030 inch can be

reworked.

(k)

Repair/Replacement of Internal and External

Support Fittings. Loose or separated support fittings can

be cleaned, buffed, cleaned again and cemented back in

place.

(3)

Damage that is not reparable is classified

as follows:

(a) Damage which extends into a comer.

step off area. or involves a cut longer than 4 inches is not

reparable.

(b) Damage which has led to activation

of the sealant ply/plies is not reparable.

(c) Damage to cells which cannot be

repaired by cement or reinforced patching is not

reparable.

(d) Hole damage which penetrates the

entire cell wall is not-reparable.

c.

Repair Fuel Cell Outer Coating, Interior/Exterior

Loose Fitting Flange and Interior Loose Seam Damage.

WARNING

Acetone, barrier cement, repair adhesives

and its components are flammable and

toxic. They can irritate skin and cause

bums. Use only with adequate ventilation

and wear a NIOSH approved air-purifying

respirator for organic vapors. Keep away

from heat or open flame. Wear safety

glasses, gloves and protective clothing to

avoid contact with skin, eyes and clothes.

If contact occurs, flush areas with water

and get medical attention for eyes.

Repair blisters, cuts, tears, snags and abrasions that

damage but do not penetrate the outer reinforcement

plies (no fabric damage) as follows:

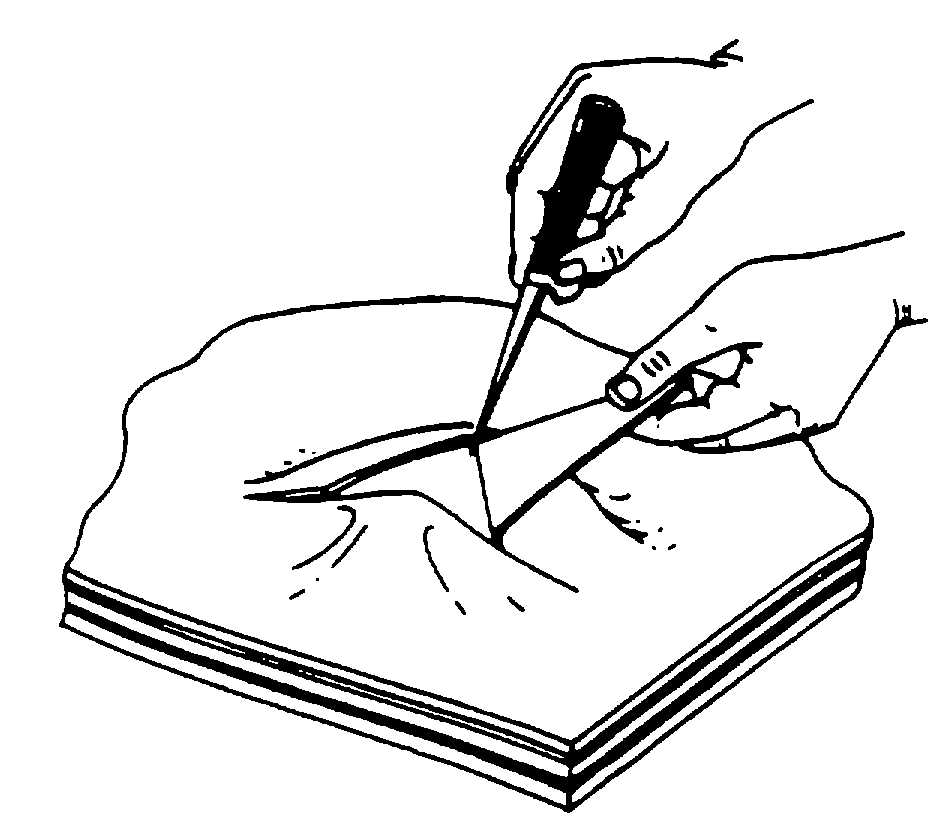

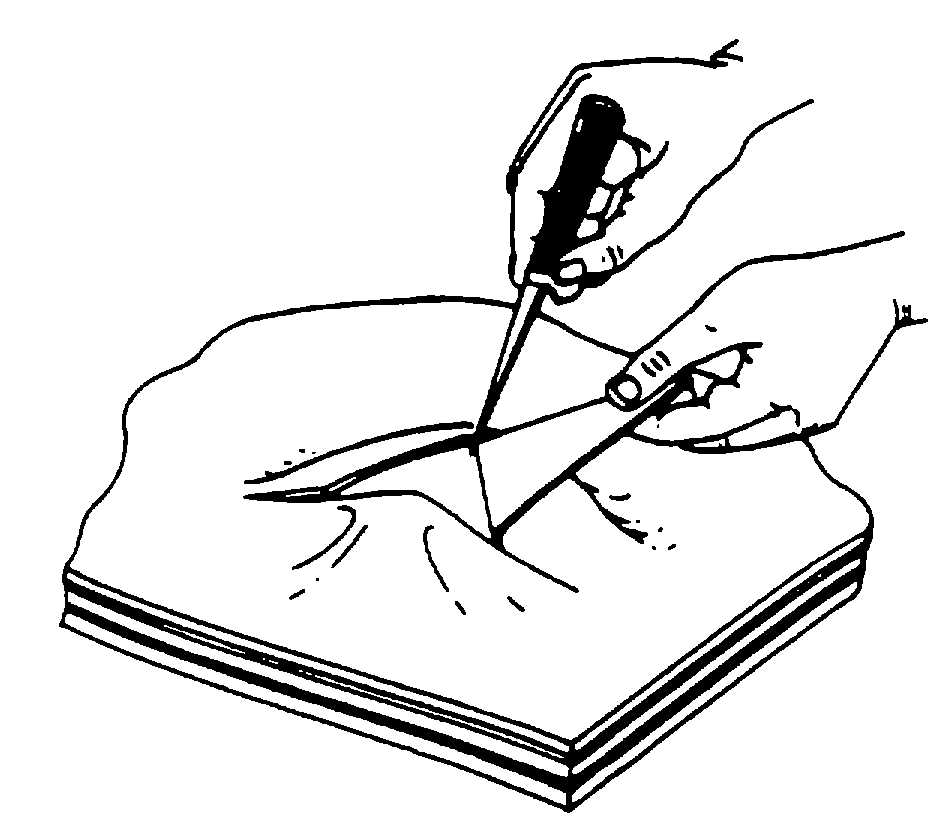

(1)

Use knife and trim away loose, damaged or

blistered outer coating (figure 2-24), except for loose

fitting flange repair.

Figure 2-24. Removing Outer Coating

(2)

Clean damaged area using a dean cloth

(item 16, table 2-11) dampened with acetone (item 3,

table 2-11). Wear gloves (item 4, table 2-11).

WARNING

Ensure all drills are non-sparking.

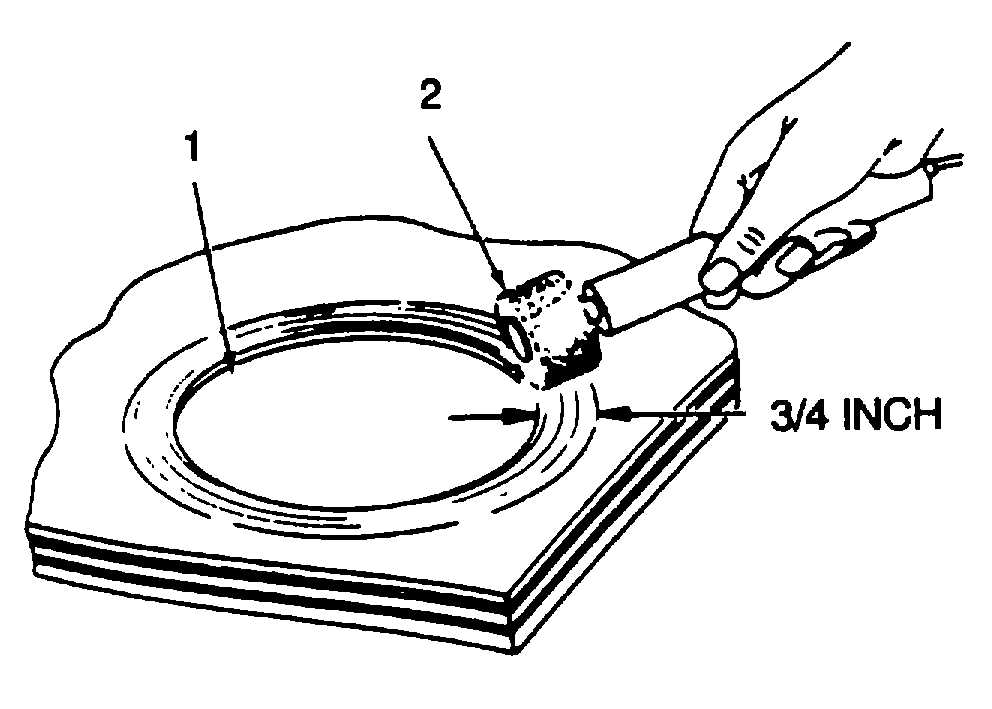

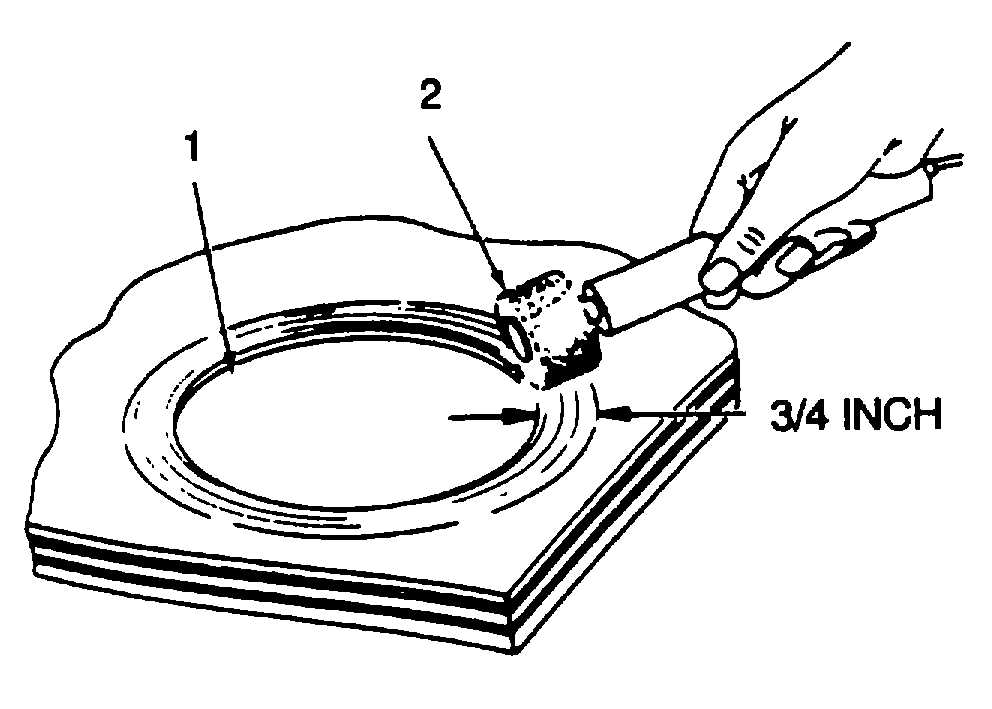

(3) Buff surface around damage 314 inch

larger in all directions than damaged area (1, figure 2-25).

Use portable drill (2), abrasive arbor, and/or scotch-brite.

Buff only to remove gloss without excessively reducing

outer coating thickness.

Figure 2-25. Buffing Damaged Area

Change 2 2-45