TM 1-1500-204-23-3

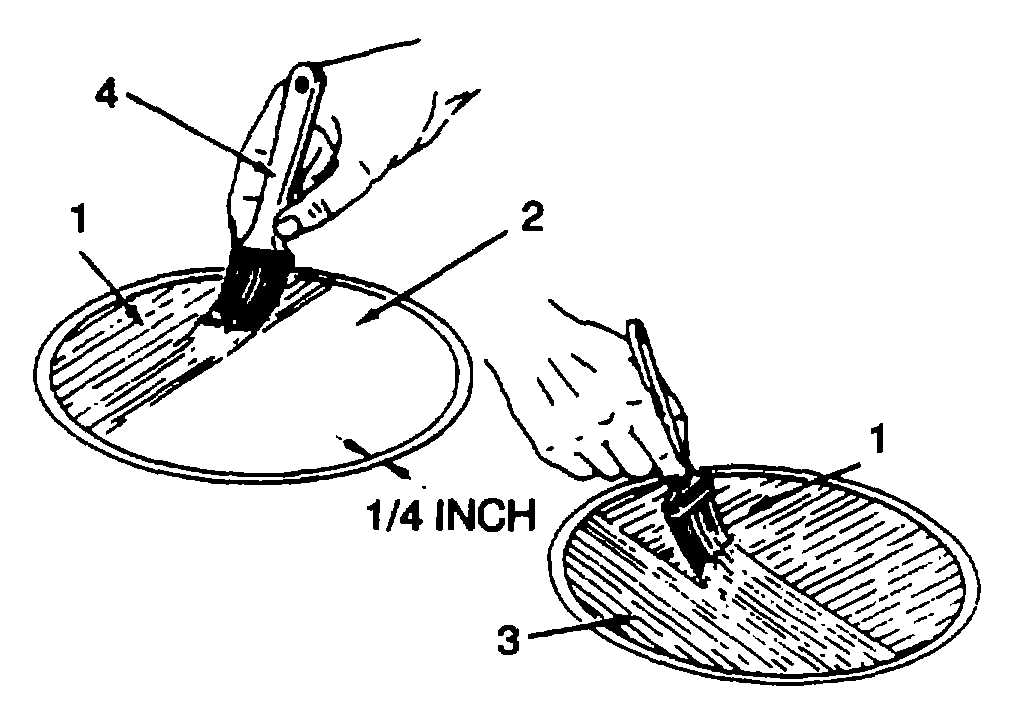

(h) Apply a uniform coat of barrier

adhesive (item 2, table 2-11 ) (1, figure 2-32) in one

direction over previous coat of repair adhesive (2) to

within no more than 1/4 inch of repair area of O.D. Use

a brush. Remove any excess adhesive from unbuffed

area. Use dean cloth (item 16, table 2-11) dampened

with acetone (item 3, table 2-11). Wear gloves (item 4,

table 2-11). Allow barrier to dry to touch.

Figure 2-32. Applying Adhesive Over Previous Coat

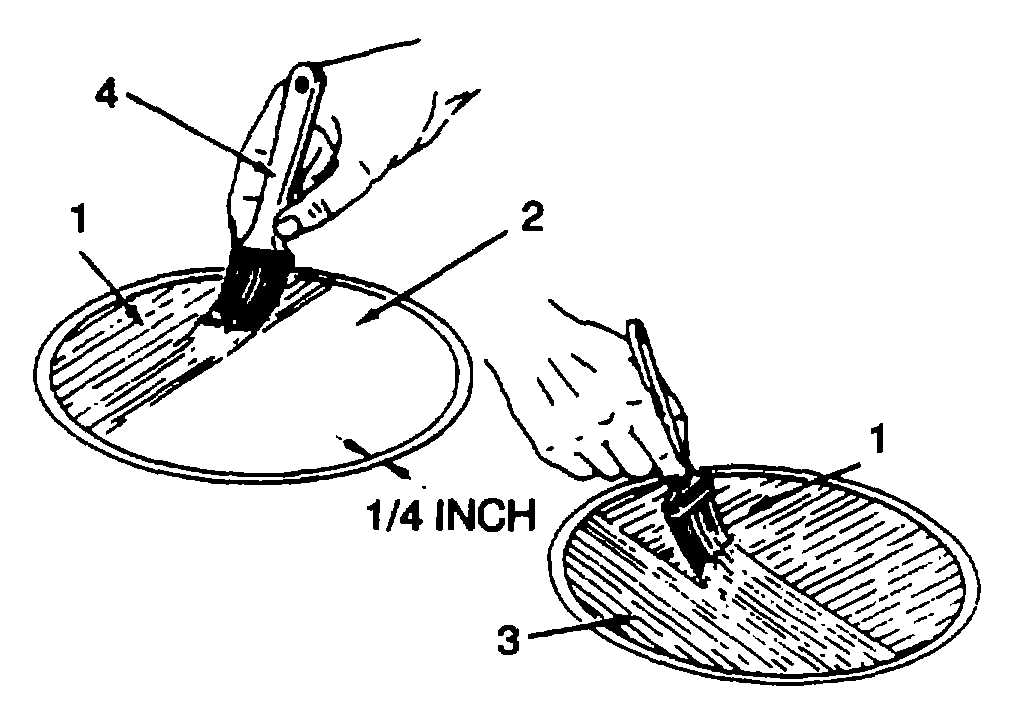

(i) Apply a second coat of barrier

adhesive (3) over first barrier coat (1) at 90 °

to the

application of first coat. Use a brush (item 6, table 2-

11). Allow second coat to air dry for approximately 30

minutes.

(j) Prepare repair adhesive as in steps

(e) and (f).

CAUTION

When

smoothing

adhesive

surface with gloved fingers wet

with acetone, lightly touch only

the

surface

of

the

adhesive.

Insure acetone does not contact

barrier cement previously applied,

as the barrier cement is soluble in

acetone. Damage to the barrier

cement can result in the barrier

being damaged.

(k) Prepare a new batch of adhesive

(item 1, table 2-11) and carefully apply a uniform

(liberal/heavy) coat of adhesive mixture (1, figure 2-30)

over previous coats of barrier adhesive to within no

more than 1/18 inch of O.D. of buffed edge area. Use

a brush (item 6, table 2-11). Smooth surface with

gloved fingers wet with acetone (item 3, table 2-11) and

remove any excess adhesive from unbuffed area Use

dean cloth dampened with acetone (item 3, table 2-11).

Wear gloves (item 4, table 2-11).

NOTE

When performing interior loose

seam damage repair, do not apply

fabric patch. Proceed to para (m).

(I) Cut a fabric patch (item 8, table 2-

11) that is 1/8 inch larger all around than the area of

barrier coverage. Dampen patch with acetone (item 3,

table 2-11), shake out excess solvent and lay the patch

into the wet adhesive. Using gloved finger and brush,

work out all air. Allow to air dry for 30 minutes.

(m) Apply a light coat of adhesive (item

1, table 2-11 ) over the fabric patch and out to the

maximum area having barrier adhesive. Do not apply

adhesive to unbuffed areas.

CAUTION

Do not flex fuel cell in repair area.

(n) Allow finished repair to set for 1

hour before moving fuel cell.

(o) Allow finished repair to air cure for

24 hours at room temperature of 70 °F (33°C) minimum

before use.

(2)

Visually inspect repair for workmanship,

no loose edges, no voids and adhesive fully cured.

f.

Repair Fuel Cell Interior Plies.

WARNING

Acetone, barrier cement, repair

adhesives and its components are

flammable and toxic. They can

irritate skin and cause bums. Use

only with adequate ventilation and

wear

a

NIOSH

approved

air-

purifying respirator for organic

vapors. Keep away from heat or

open flame. Wear safety glasses,

gloves and protective clothing to

avoid contact with skin, eyes and

clothes. I contact occurs, flush

areas with water and get medical

attention for eyes.

Change 2 2-50