TM 1-41500-204-23-4

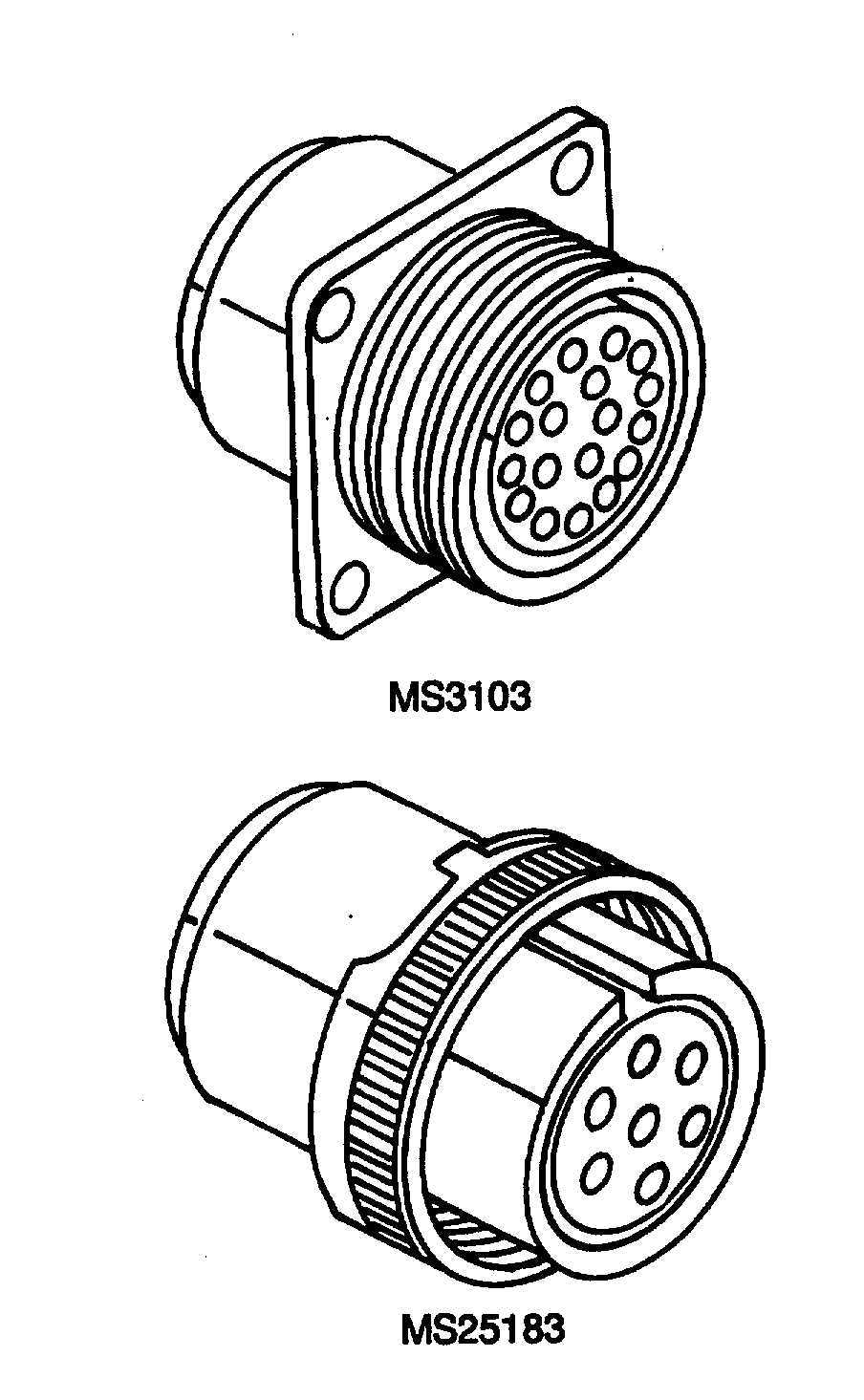

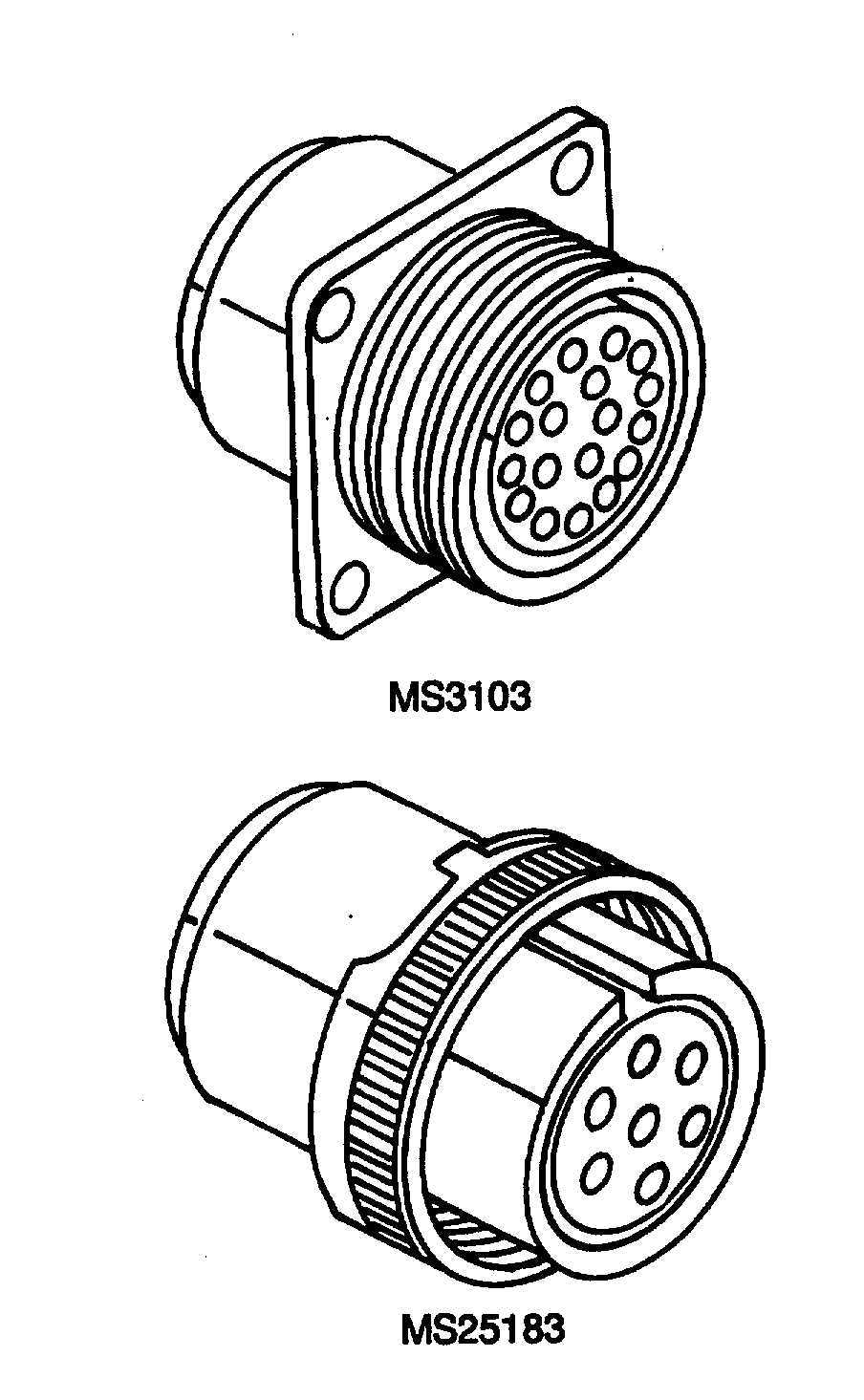

Figure 3-7. Potting Connectors

(4) Check fuses in associated circuitry for

correct current rating.

(5) Ensure installation of MS3057 cable

damp adapters on all MS connectors except those that

are moisture-proof.

(6) Ensure that vinyl tape is wrapped around

wires in MS3057 cable damp adapters so that tightening

of the cable damp adapter cap provides sufficient grip

on the wires to keep tension from being applied to the

connector pins.

(7)

Ensure

that

unused

plugs

and

receptacles are covered with moisture-proof paper, tied

with waxed cord, and appropriately tagged to indicate

the circuit or accessory with which associated. The units

will then be secured with damps to the aircraft structure

or to other wiring that is properly anchored.

(8) Ensure that the coupling nut of AN

connectors is lockwired as required by the applicable

aircraft maintenance handbook.

(9) Ensure that moisture-absorbent type

material is not used as fill for MS3057 damps or

adapters.

(10) Ensure that there is no evidence of

deterioration of potting compound in potted connectors.

(11) Replace cracked dielectric inserts.

c. Installation of Connectors on Wires. The

following paragraphs describe how solders and other

fastening means are matched to the wire type and to the

installation as follows.

(1) Soldering. Soldering is used for tin-

coated copper wire, coaxial, cable, and silver-coated

copper wire.

(a) Tin-lead solder. Soft solder-60/40

tin-lead (Federal Specification QQ-S-571, composition

Sn 60) is used for fin-coated copper wire and for coaxial

cable.

(b) Lead-silver solder. Soft solder-

lead-silver

(Federal

Specification

QQ-S-571,

composition Ag 2.5 or Ag 5.5) is used for silver-coated

copper wire.

NOTE

Solder cup contacts are silver or

gold plated to provide low contact

resistance. Silver plated contacts

have pretinned solder cups. Gold

plated contacts are not pretinned

because

the

gold

prevents

oxidation and is therefore always

easy to solder.

(2) Crimping. Crimp connections are used

for nickel-dad copper wire, and tin, silver, or nickel

coated copper wire.

3-4. Electrical System Components. Various

electrical system components used in Army aircraft are

explained in the applicable maintenance manual.

a. Storage Battery. The battery provides engine

starting power, back-up emergency power, and gun

drive power during firing of the turret weapons. The

battery installation usually includes vent tubes, eyebolts

for attaching tiedown rods, and a battery cable.

(1) Inspection. Inspect for corrosion,

overheating, and overcharging. Every 120 days or

every 100 flight hours, remove the battery and return to

direct

3-13