TM 1-1500-204-23-9

4

Using adapters and a hoist if

necessary, disassemble the engine as required.

5

After the engine is reassembled, it

may be removed from the engine maintenance stand by

reversing these procedures.

(e)

Inspection. The operator should visually

look at the welds for cracks and check the rail stops for

proper operation prior to using the stand.

(f)

Maintenance. Consult the applicable

maintenance manual for scheduled and preventive

maintenance requirements.

(g)

Sweeney

adapters.

Consult

the

applicable engine maintenance manuals for adapters

that can be used. TM 1-1500-204-23-9

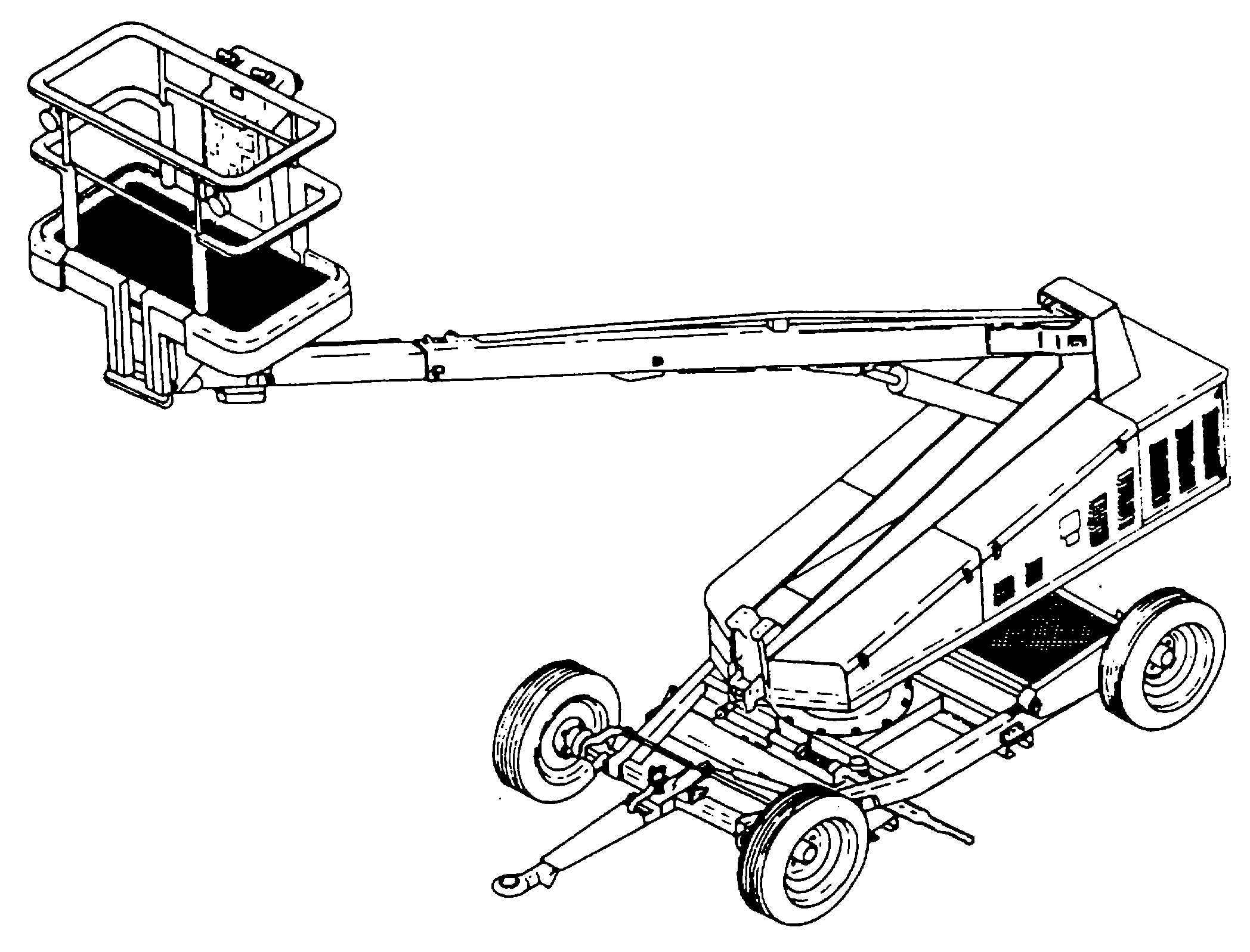

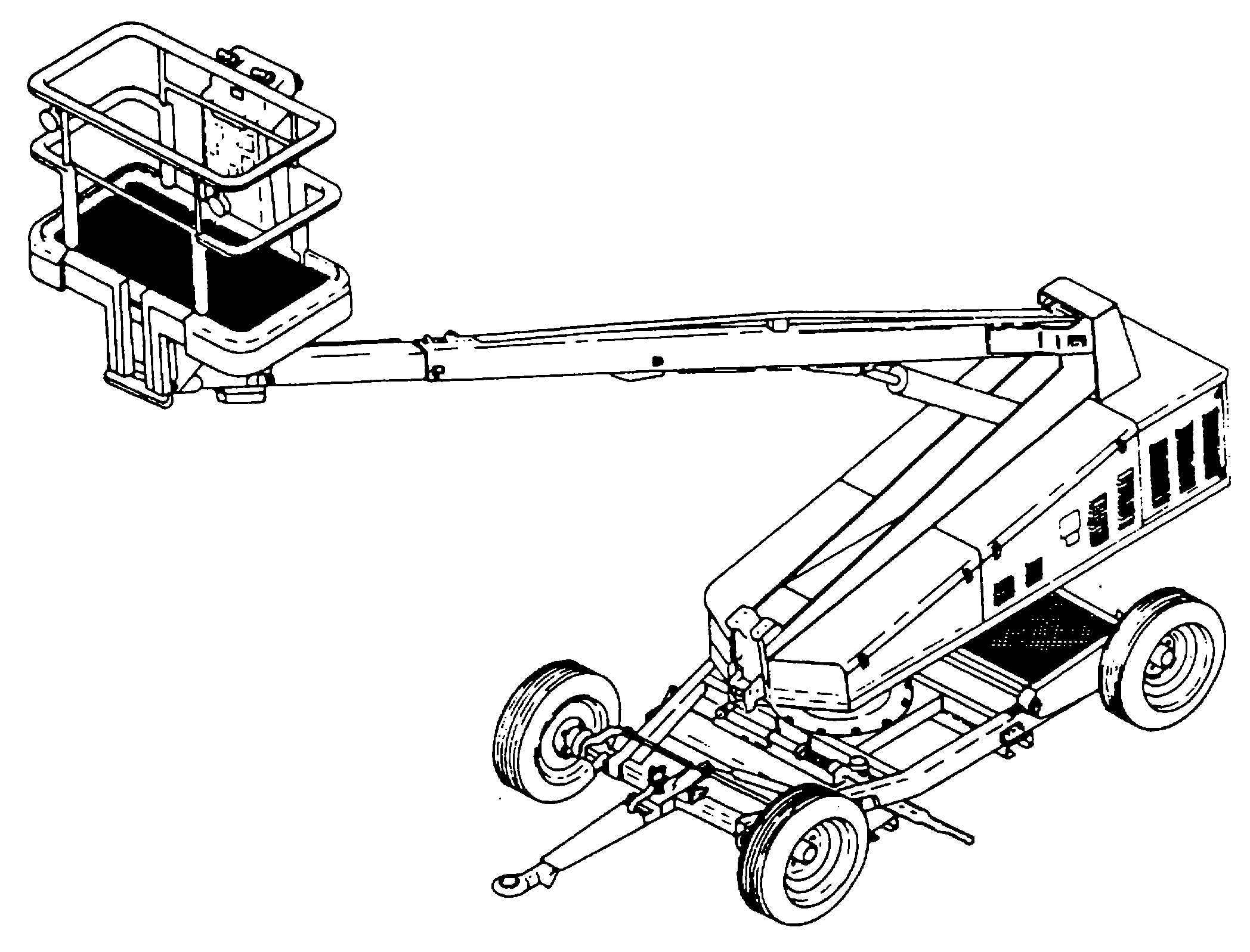

(4)

Self-propelled

elevated

maintenance

workstand. The Self-Propelled Elevated Maintenance

(SPEM) workstand, shown in figure 9-4, is driven by a

gasoline engine. The stand is self propelled at 2 mph

and can be driven from the workbasket.

(a)

Purpose. The SPEM stand is useful for

reaching areas of an aircraft that are not accessible

from a type B-1 or Type B-4A stand. The extendable

arm allows the workbasket to go over the aircraft and to

a height of 40 feet.

(b)

Principles of operation. The SPEM stand

is counterbalanced and propelled by a gasoline I engine.

The rear drive wheels are equipped with hydraulic

brakes that engage automatically when the drive control

is released. The front steering wheels have electric

brakes which are operated from the workbasket. The

turntable is hydraulically-operated and cab be rotated

350 degrees from the workbasket.

Figure 9-4. SPEM Stand

Change 2 9-29