TM 1-1500-204-23-9

(c)

Safety practices and procedures.

The following special precautions should be observed

when using the SPEM stand:

· Do not exceed the weight capacity of

the workbasket.

· Check the area before lowering the

workbasket or rotating the turntable.

· Do not try to propel the stand from the

workbasket with the hand parking brake

engaged.

(d)

Operating

procedures.

The

following procedures pertain to the operation of the

SPEM stand:

1

Tow the stand to the work site.

2

Use the self-propelling motor to

locate the stand in a working position.

3

Enter the workbasket and position it

as necessary using the extendable arm, self-propelling,

and turntable capabilities.

4

Reverse these procedures to stow

the stand when the work is complete.

(e)

Inspection. The following general

operator inspection apply to the SPEM stand.

1

Visual inspection. Look over the

entire stand for obvious damage or leaks.

2

Batteries. Check electrolyte level.

3

Hydraulic reservoir. Check fluid

level. Service if necessary.

4

Tires. Check for proper pressure.

(f)

Maintenance.

Consult

the

applicable maintenance manual for preventive and

scheduled maintenance requirements.

c.

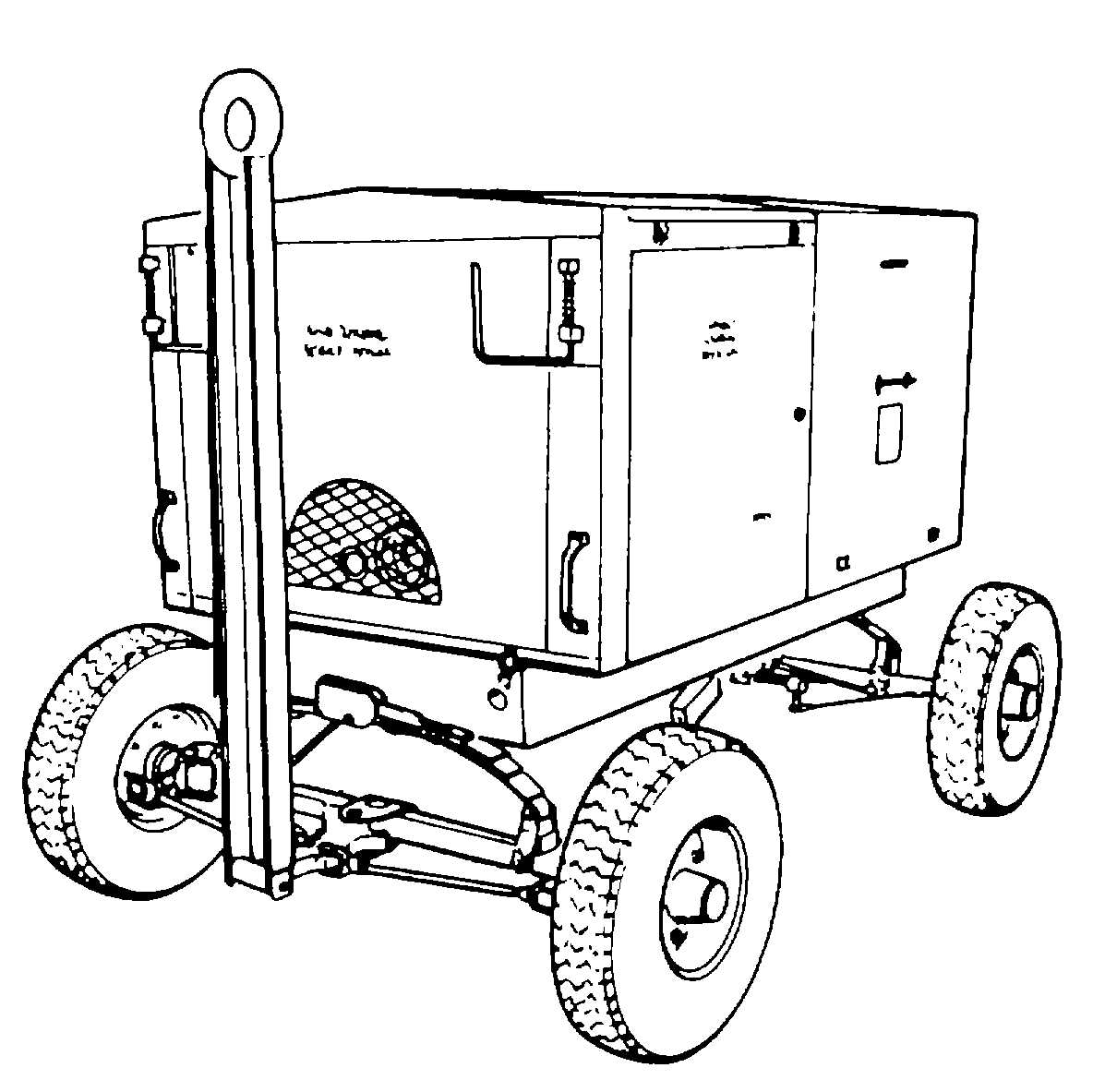

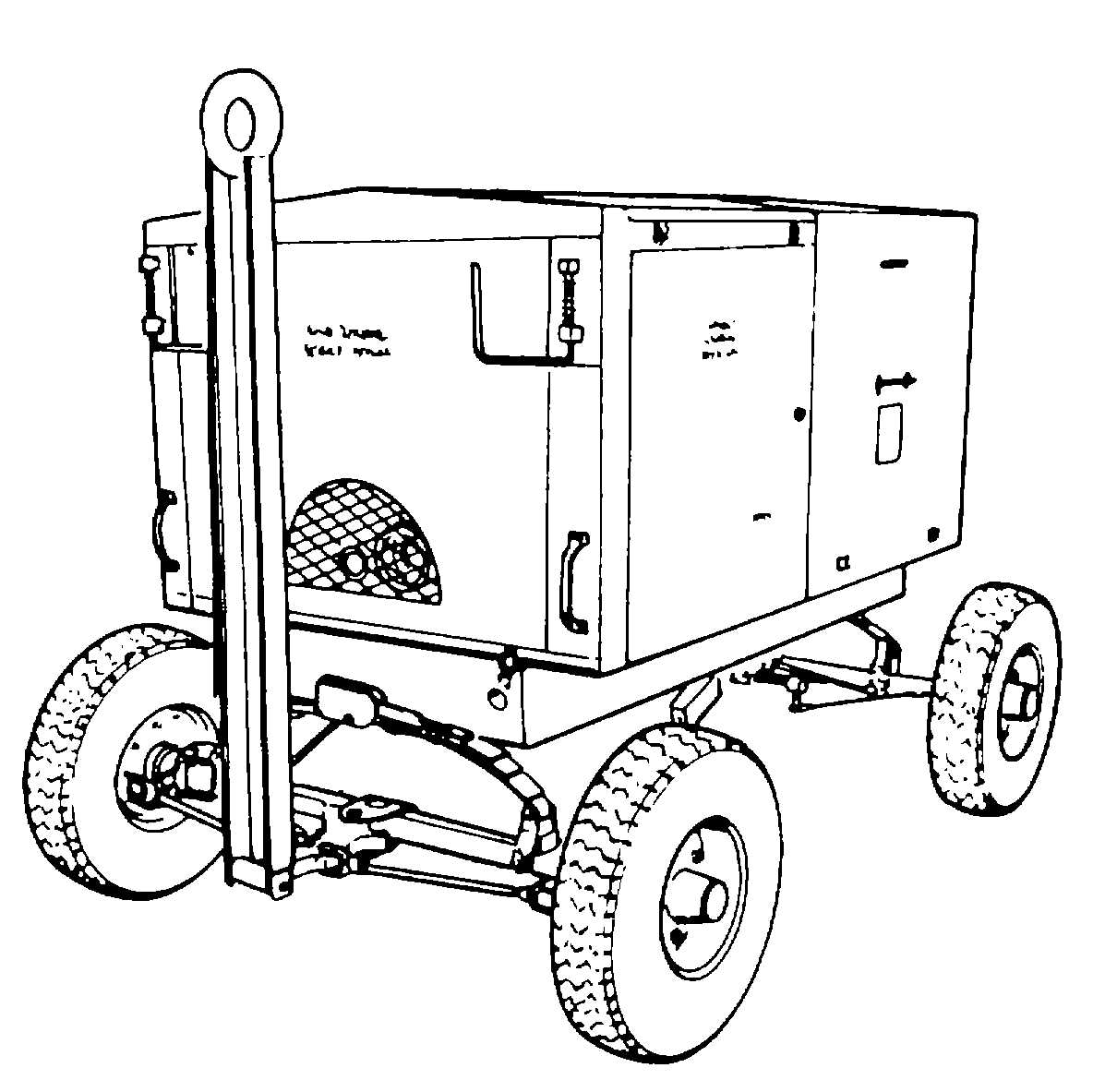

Hydraulic Test Stand. The hydraulic test stand,

shown in figure 9-5, is a mobile, self-contained hydraulic

testing unit. It is enclosed in a steel, weather resistant

housing, mounted on a trailer assembly that has a two

bar to permit towing with a vehicle. Access to

components in the housing is provided by doors.

Figure 9-5. Type D5 Hydraulic Test Stand

9-30