NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-30

13 02

1 September 2011

Page 10

NOTE

For the AA-400 Super Heater use the: No.

979663

Mini-Solder

Sleeve

reflector

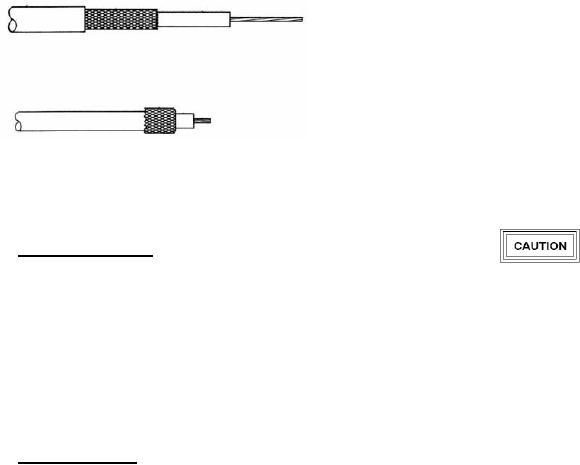

Conventional Stripping Method

(required) and AA-400-140 magnifier bracket

assembly (optional).

For the CV-5300 MiniGun use the MG-1

reflector 4.

Braid Fold-Back Stripping Method

e. Turn the heating tool on and allow to warm

up. (See instructions for tool used.)

Figure 4. Coaxial Cable Stripping Methods

28. Holding Fixture Setup.

a. Install the appropriate adapter (Figure 3) onto

The heating tools have hot nozzle surfaces

the AD-1319 holding fixture.

and produce hot air that can cause burns.

To prevent burns, do not touch the nozzle and

b. Insert a contact in the adapter and set up as

keep hands and fingers away from the hot air

shown in figure 7. Ensure that the contact is inserted in

stream.

the appropriate end of the adapter: D-602-0141 and D-

602-0171 outer socket contacts in the "S" end. If using

f.

Heat the contact as follows:

a hot-air heating tool, the spacer collar is not needed,

but may be left in place.

1). Using the holding fixture, position the

contact in the heating tool reflector as shown in Figure

29. Heating Procedures.

10, with the forward inspection window centered in the

reflector

a. Insert the contact/cable assembly into the

appropriate end of the adapter (Figure 7) or repair

2). Continue heating until the small solder

holding fixture (Figure 7).

preform in the forward inspection window has melted

and flowed. The large solder preform in the rear

b. D-602-0141 or D-602-0171 outer socket

inspection window should have melted and flowed by

contacts in the "S" end.

this time; if it has not, direct hot air at the rear

inspection window until it does.

c. Clamp the cable in the AD-1319 (or AD-1567)

holding fixture.

NOTE

NOTE

If contact is UNDERHEATED, there will be

The cable must remain fully inserted in the

visible remnants of the original shapes of the

contact.

solder performs. An under heated contact

must be reheated.

The contact must be fully inserted in the

adapter.

If contact is OVERHEATED, solder will

wick away from the joint areas, leaving no

The cable must be straight between the

solder fillets. An overheated contact must be

contact and the cable clamp.

removed and a new contact installed.

d. Attach the appropriate reflector and other

g. After the contact has cooled for at least 10

applicable accessories to the heating tool.

seconds, remove the contact and cable from the holding

fixture.