TM 1-1520-264-23

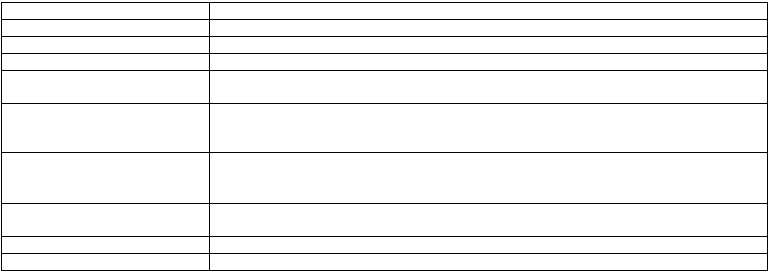

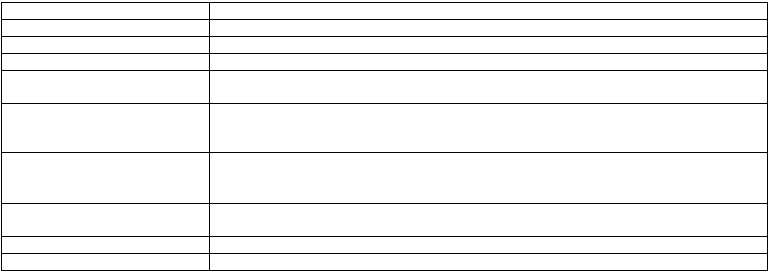

Table 1-3. Penetrant Procedure (Type I, Method A)

Task

Description

a.

Preparation of Part:

Refer to Preparation of Part or Area for.ND!, paragraph 1.4.4.

b.

Precleaning Procedure:

Refer to TM 1-1500-344-23.

c.

Penetrant Application:

The penetrant may be applied by brushing, spraying, or dipping.

d.

Penetrant Dwell:

Allow a minimum of 30 minutes dwell time to a maximum of 240 minutes. Extended

dwell time may require rewetting of parts.

e.

Penetrant Removal/Rinse:

Rinse the part by waterwash using a low-pressure spray (pressure not to exceed 20

PSI) and a temperature of

16°C to 38°C (60°F to 100°F). DO NOT OVERRINSE.

f.

Drying Operation:

The parts should be dried in a circulating air dryer with a temperature range from 38C

to 60°C (100°F to 140

°F). The time in the dryer should not exceed the time

necessary to completely dry the surface of the parts.

g.

Developer Application:

The dry developer is sprayed or dusted lightly over the part to be inspected. Shake or

blow off with low, oil-free air to remove excess developer.

h.

Inspect:

Perform inspection under black light.

i.

Materials:

Type I, Method A, Level 3 or 4 (water washable) Penetrant.

1-28