TM 55-2840-241-23

12-2 Change 19

c.

Visually inspect the N1 turbine first-stage blades.

Replace the engine if any of the following conditions

exist:

(1)

Damaged inner 1/3 of blade.

(2)

Blade broken off.

(3)

Cracked blade. If cracks are suspected, refer

to TM 1-1520-254-23, technical manual Aviation Unit

Maintenance (AVUM) and Aviation Intermediate Mainte-

nance (AVIM) manual Nondestructive Inspection Proce-

dure for OH-58 helicopter series.

(4)

Melted blade.

d.

Inspect the combustion liner. (Refer to table

7-1.)

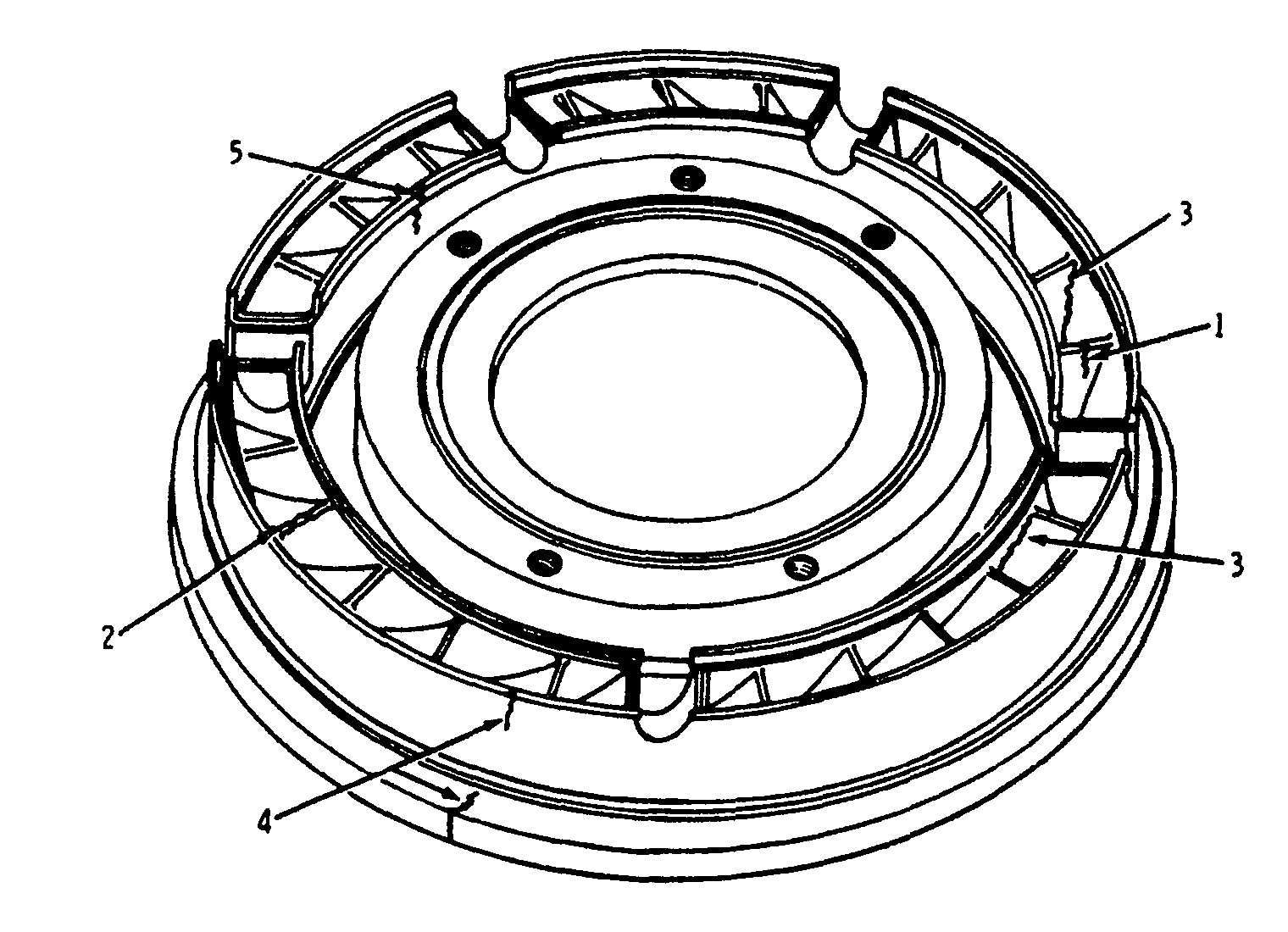

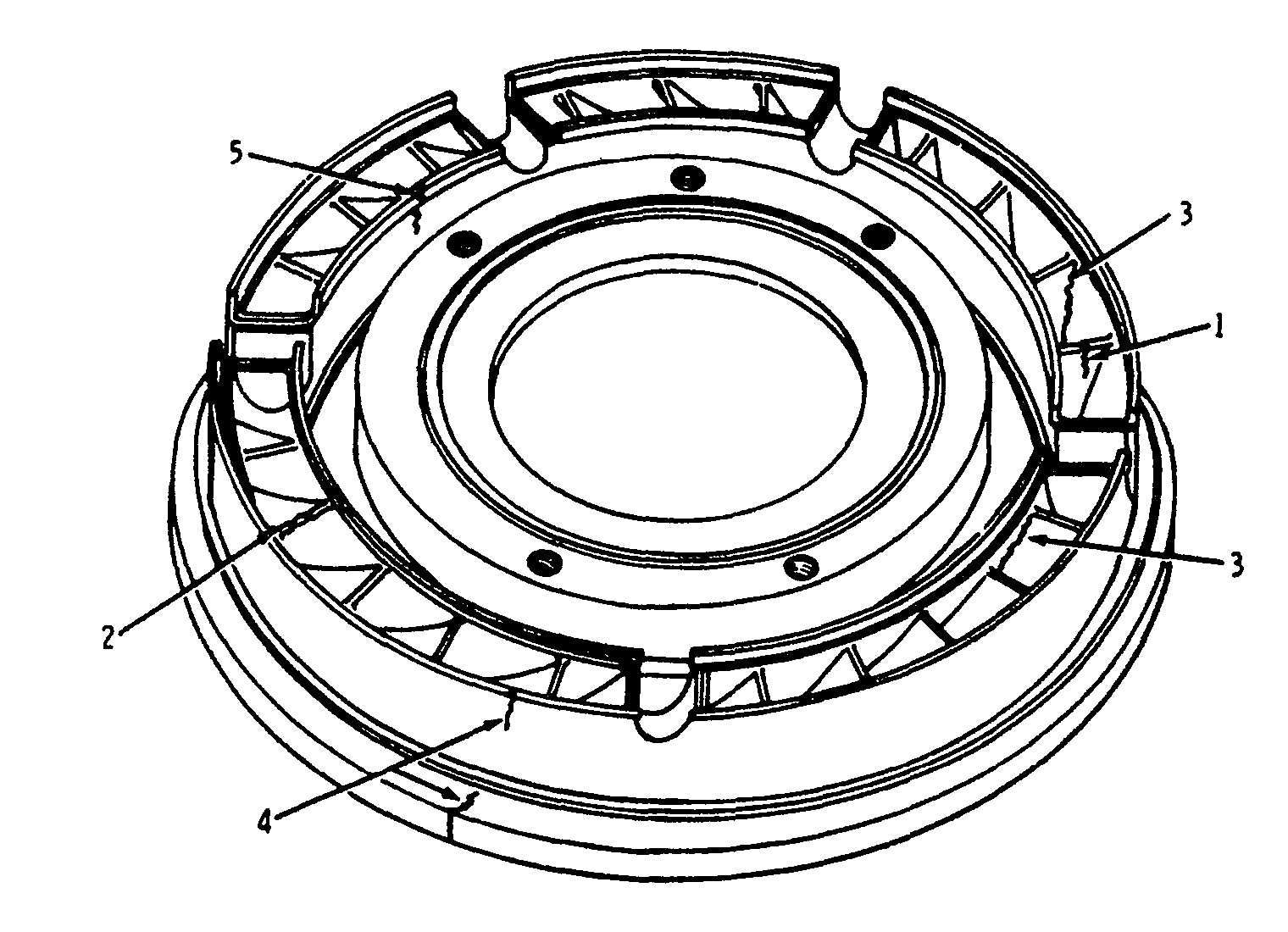

Table 12-3. First-Stage Turbine Nozzle and Shield Inspection

Item

Condition

Serviceable limits

First-Stage Nozzle

1

Axial cracks in vane airfoil.

Leading edge 1/4 in. maximum; trailing edge 5/16 in maximum.

a. No two cracks in same plane.

b. Adjacent cracks 1/4 in. apart.

c. Adjacent cracks not progressing toward each other.

2

Nicked or dented leading

and trailing edge. Warped

or burned trailing edge only.

Leading edge 1/16 in. maximum; trailing edge 1/8 in. maximum.

3

Fillet cracksÐinner and

outer band.

Leading edge 1/4 in. maximum; trailing edge 1/8 in. maximum.

4

Outer band cracksÐleading

and trailing edges.

Visible portion of crack extends 3/16 in. maximum axially into

the band and not in line with crack on opposite edge.

5

Inner band cracksÐleading

and trailing edges.

Leading edgeÐvisible portion of crack extends 3/16 in. maxi-

mum axially into the band and not in line with trailing edge

cracks.

Trailing edgeÐextending through inner band to sheet metal

detail.

First-Stage Nozzle Shield

6

Cracks around spotwelds

on heat shield.

Cracks are acceptable provided the length of the crack is not

greater than 50 percent of the distance around the weld.

1 VANE AIRFOIL CRACKS

2 VANE EDGE DAMAGE

3 FILLET CRACKS

4 OUTER BAND CRACKS

5 INNER BAND CRACKS

9766

PIN: 033211-019

Figure 12-1. Typical First-stage Turbine Nozzle