2225A

TM 55-2840-241-23

Change 19 3-13

dry or wipe with a clean lint-free cloth. Blow out all crev-

ices with dry, filtered, low-pressure compressed air.

c.

Coat external bare metal surfaces including the

splines with corrosion preventive compound (item 12,

table 2-2).

d.

Attach a properly filled out DD Form 1577-2 (Un-

serviceable-Reparable tag). Refer to paragraph 3-9 for

additional information concerning tags.

e.

Prepare DA Form 2410 (Component Removal

and Repair/Overhaul Record) according to DA PAM

738-751 and place in a greaseproof envelope. (Refer to

paragraph 3-9.)

f.

Wrap the governor with barrier material (item 4,

table 2-2) to prevent contact with the cushioning materi-

al and to prevent the loss of the corrosion preventive

compound. Secure barrier material with pressure-sensi-

tive tape (item 5, table 2-2) .

g.

Prepare the container for use in accordance with

paragraph 3-15i.

h.

Install the governor upright in the container in

accordance with paragraph 3-15j.

i.

Stencil the container in accordance with para-

graph 3-9 and figure 3-5.

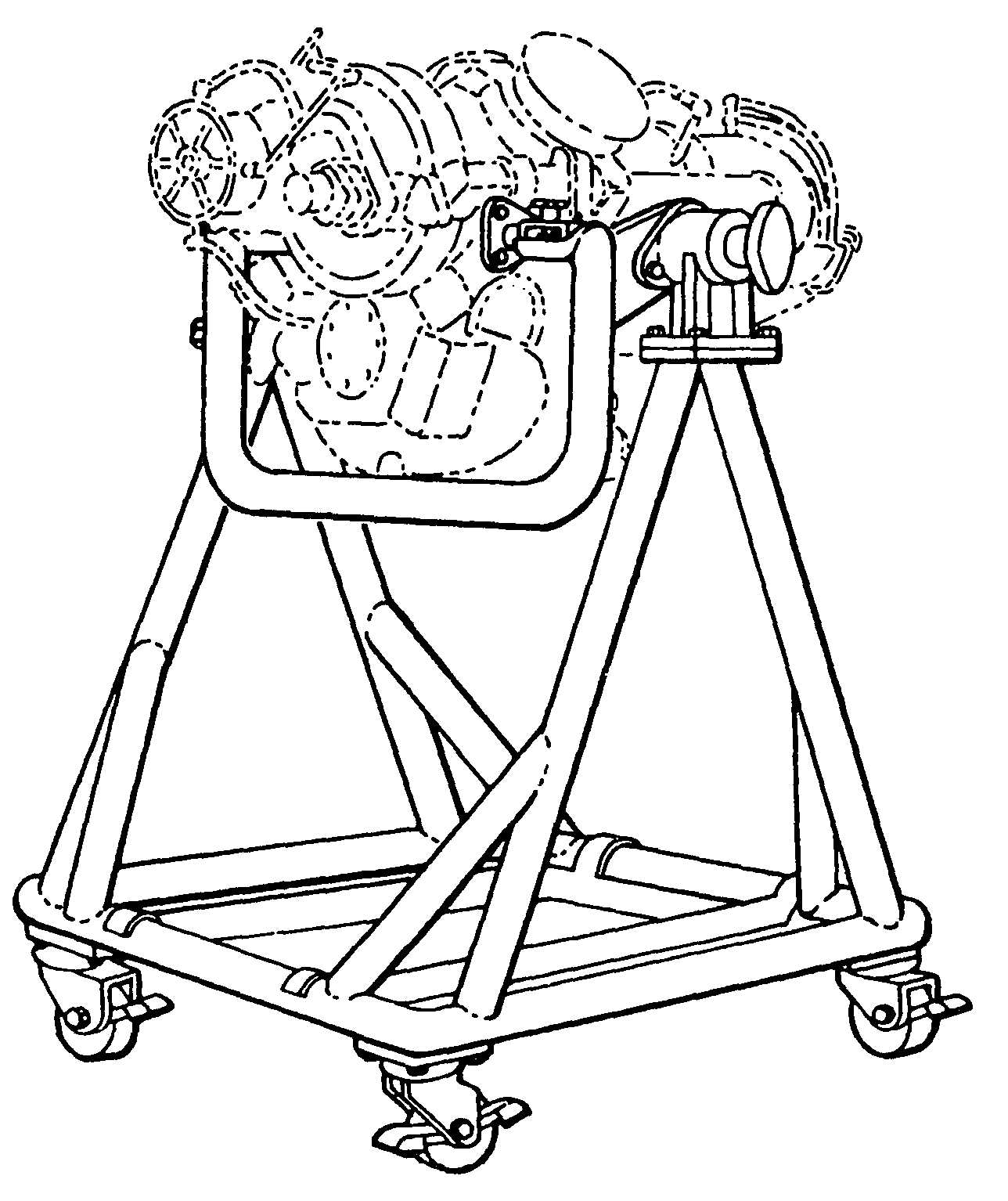

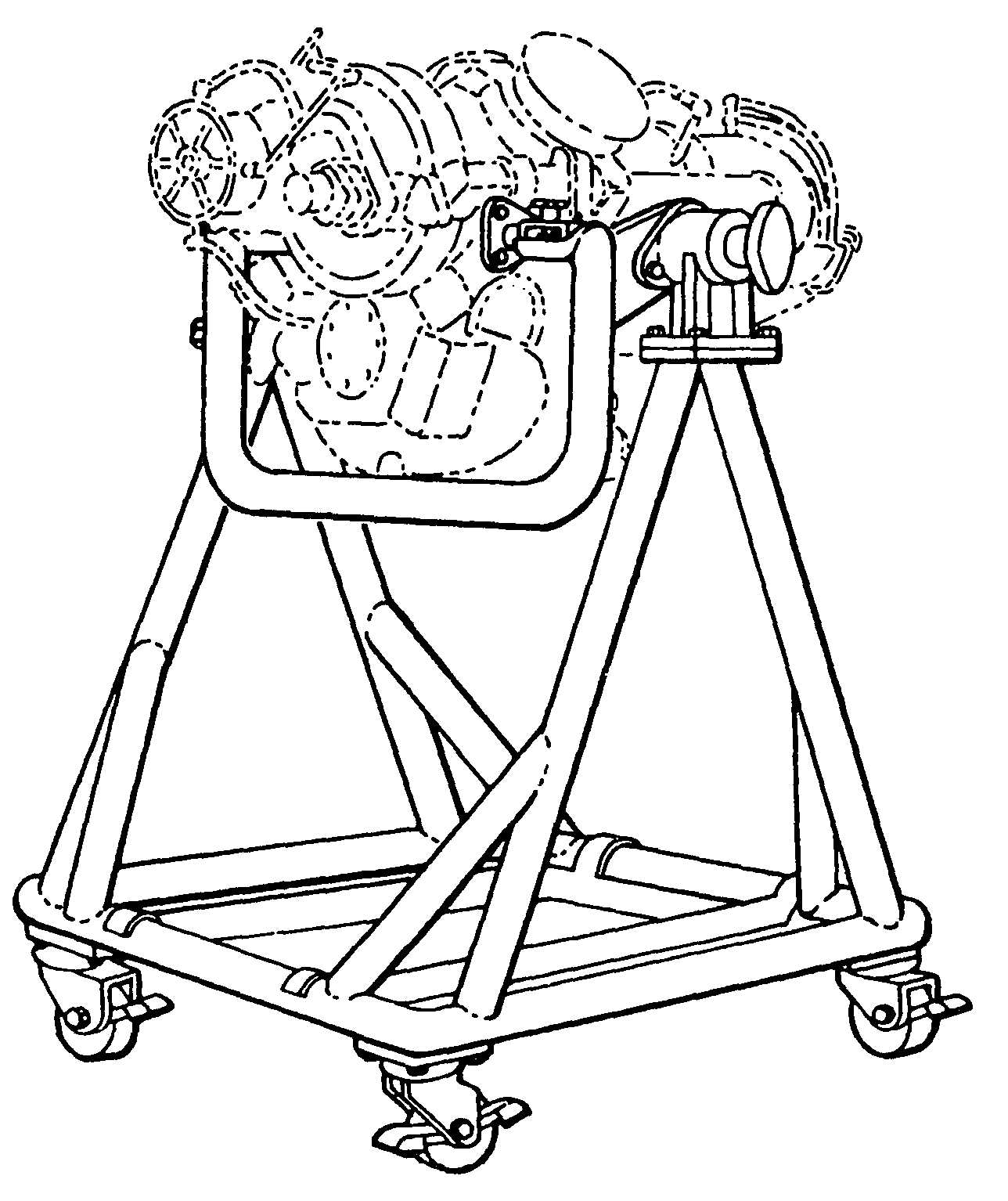

Section II. ENGINE HANDLING

3-18. Scope.

This section provides instructions for installation of

the engine in the turnover stand and dismantling of the

engine into major functional assemblies.

3-19. Installing Engine in Turnover Stand.

a.

Install engine assembly lift, tool No. 6796963 on

the gearbox top mounting pad and suspend the engine

from a hoist.

NOTE

Do not use the shipping container or airframe

mounting brackets in lieu of the turnover

stand mounting brackets.

b.

Install the three turnover stand, tool No. 6795579,

mounting brackets on the gearbox side and bottom

mounting pads. (See figure 3-7.)

c.

Lower the engine into the turnover stand. Ensure

that the three mounting brackets installed on the gearbox

engage the mounting bosses on the turnover stand.

d.

Slide the two clamps at the gearbox side mounts

in to engage the mounting brackets and tighten the hand

knobs.

e.

Remove the hoist and lifting tool.

Figure 3-7. Engine Assembly Turnover Stand

No. 6795579.