TM 55-2840-241-23

Change 19 3-11

3-15. Preparing Fuel Pump and Filter Assembly for

Storage and Shipment.

NOTE

The procedure for removing the fuel pump

and filter assembly from the metal shipping

and storage container is prescribed in para-

graph 3-13.

Prepare the fuel pump and filter assembly for storage,

shipment, and installation in a metal shipping and stor-

age container, MS63052-1, as follows:

a.

Clean the exterior of the fuel pump with a clean

cloth dampened with solvent (item 3, table 2-2). Air dry

or wipe with a clean lint-free cloth . Blow out all crevices

with dry, filtered, low-pressure compressed air.

b.

Pump lubricating oil (item 37, table 2-2) into fuel

inlet port until fuel-free oil flows from the outlet port. Drain

excess oil from the fuel pump.

NOTE

If the engine fuel system was preserved in

accordance with paragraph 3-10, subpara-

graph b above may be omitted.

c.

Install shipping plugs in all ports to prevent entry

of foreign material.

d.

Coat external bare metal surfaces including the

splines with corrosion preventive compound (item 12,

table 2-2).

e.

Attach a tag to the fuel pump stating: FUEL

PUMP PRESERVED WITH LUBRICATING OIL,

MIL-L-6081, GRADE 1010.

f.

Attach a properly filled out DD Form 1577-2 (Un-

serviceable-Repairable tag). Refer to paragraph 3-9 for

additional information concerning tags.

g.

Prepare DA Form 2410 (Component Removal

and Repair/Overhaul Record) according to DA PAM

738-751 and place in a greaseproof envelope (Refer to

paragraph 3-9).

h.

Wrap the fuel pump with barrier material (item 4,

table 2-2) to prevent contact with the cushioning materi-

al and to prevent the loss of the corrosion preventive

compound. Secure barrier material with pressure-sensi-

tive tape (item 5, table 2-2) .

i.

Prepare the container for use as follows:

(1)

Loosen nut (7, figure 3-4) and remove the

ring (6), cover (9), gasket (10), and top cushion (1) from

body (4).

(2)

Check gasket (10) for damage or deteriora-

tion and replace if necessary.

(3)

Check the container for cleanliness and gen-

eral condition.

j.

Install the fuel pump in the container as follows:

(1)

Install the fuel pump upright in the container.

Ensure that it is properly seated in the bottom cushion (2,

figure 3-4).

(2)

Install top cushion (1) in the container. En-

sure that it is properly seated over the pump.

(3)

Plate two bags of dehydrating agent (item

11, table 2-2) in the voids on each side of top cushion (1)

one bag per side.

(4)

Place the fuel pump assembly records in one

of the voids at the side of the top and bottom cushions.

Tape the three-spot humidity indicator card (3) on the

side of the top cushion.

(5)

Place gasket (10) on cover (9). Install the

cover on body 14) and secure with ring (6).

(6)

Slowly tighten nut (7) while tapping on the

locking ring until 65-75 in. lb torque is obtained. Secure

the nut with wire seal (8).

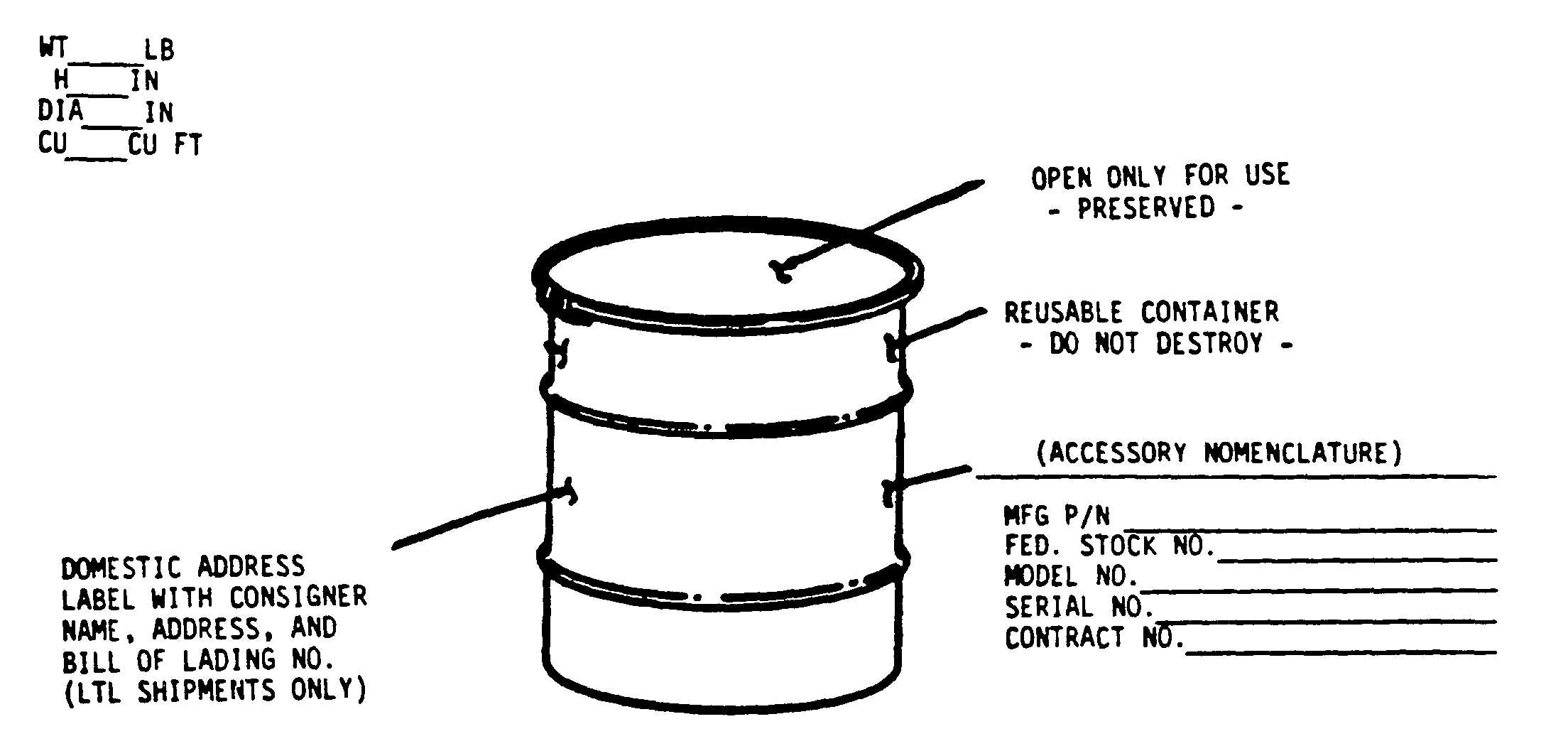

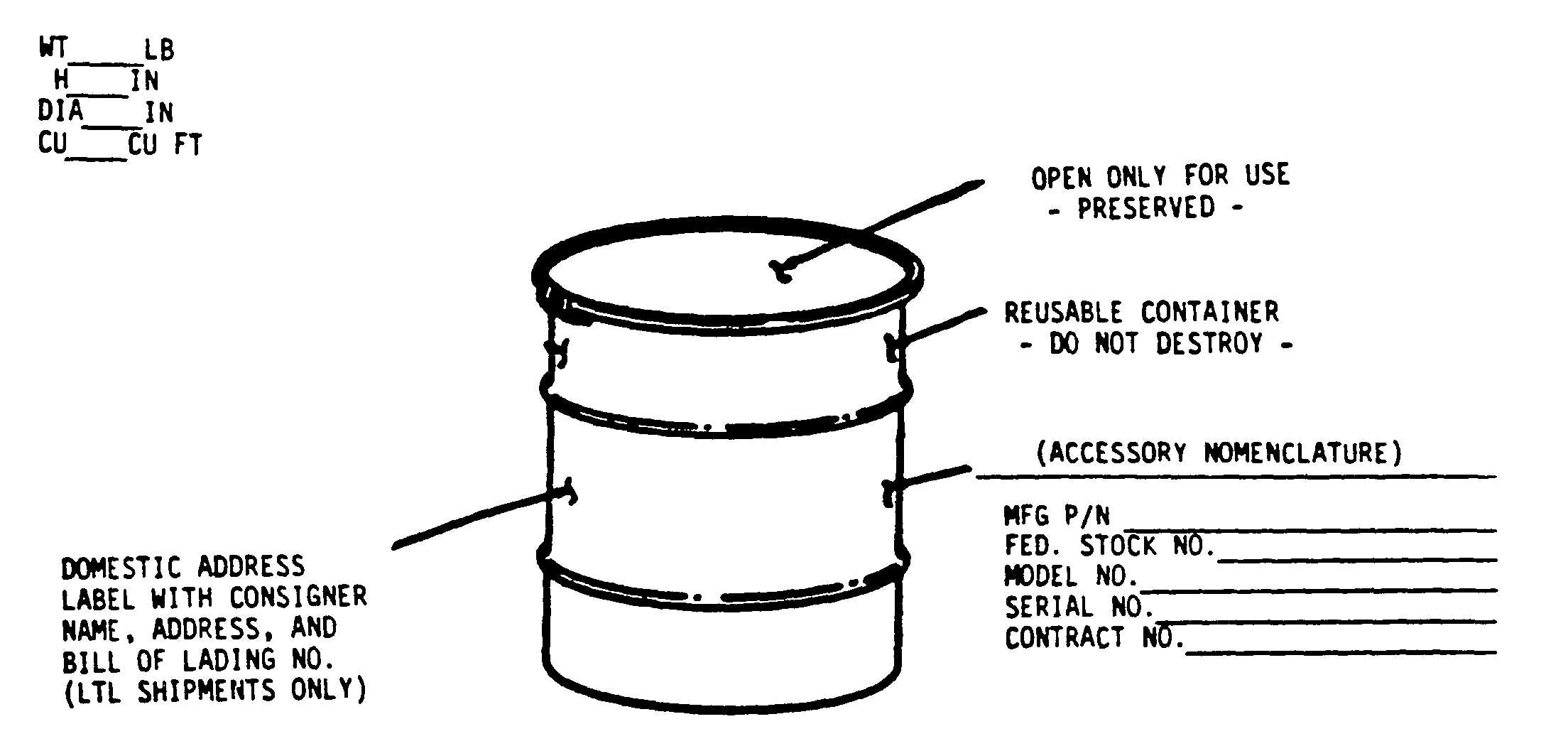

k.

Stencil the container in accordance with para-

graph 3-9 and figure 3-5.

Figure 3-5. Accessories Shipping Container Stenciling