TM55-2840-251-23

3-2 INNER (SMALL) EXIT DUCT, SHROUD AND VANE ASSEMBLY (AVIM)

(Continued)

3-2-5 ASSEMBLE (Cont)

1. Select vanes as follows:

(Cont)

b. The average class (step

a.) shall be within 11.9 and

12.6.

c. If average is too high,

substitute a sufficient number of

vanes of a lower classification

to reduce the class average with-

in specified limits.

d. Conversely, if average

is too low, substitute a suffi-

cient number of vanes of a higher

classification to increase the

class average within specified

limits.

e. If more than one classi-

fication of vane (meaning of full

class, eg., CL11, CL12, CL13) is

required in a vane assembly, a

maximum of three consecutive full

classes may be used, provided the

spread between adjacent vanes is

not more than two classes. Vanes

of the same class should be dis-

tributed as equally as possible

around the vane assembly.

2. Install vanes as follows:

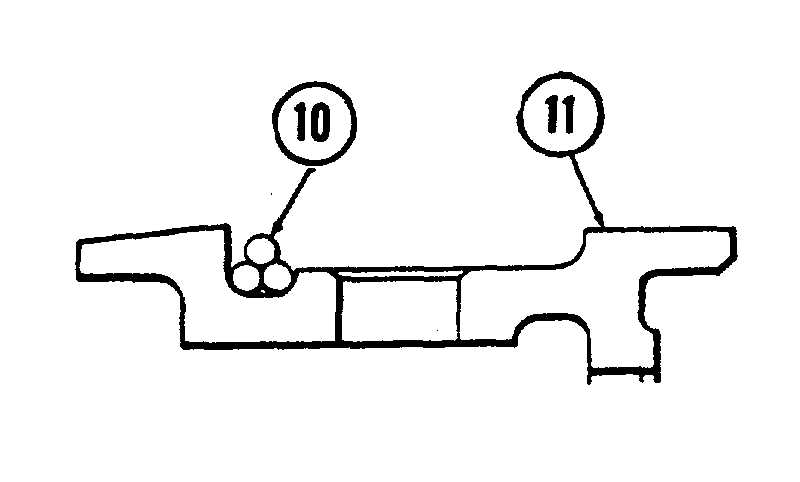

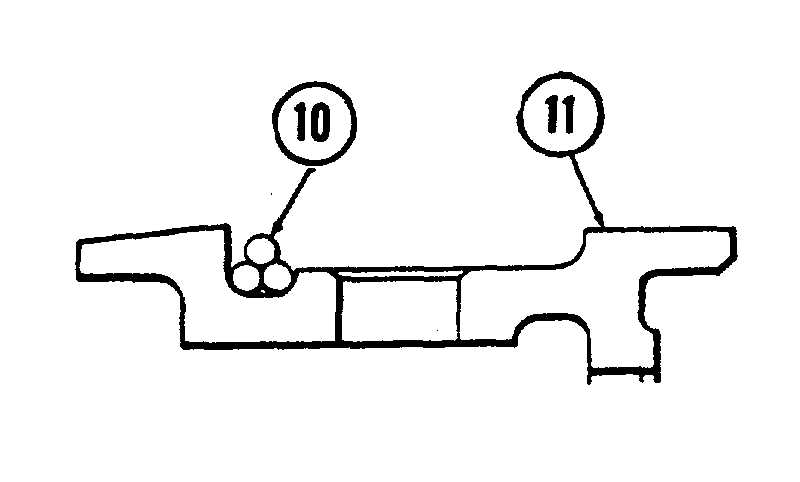

a. Cut three lengths of

ceramic fiber cord (10), each

longer than circumference of

front outer groove of compressor

turbine vane support (11). Lay

cords side-by-side so that ends

are staggered, then entwine to-

gether. Install entwined cords

in front outer groove of support

(11), insuring that there is no

gap where cord ends meet.

GO TO NEXT PAGE

3-19