TM55-2840-251-23

Section III PRINCIPLES OF OPERATION (Continued)

1-11 FUEL SYSTEM (Cont)

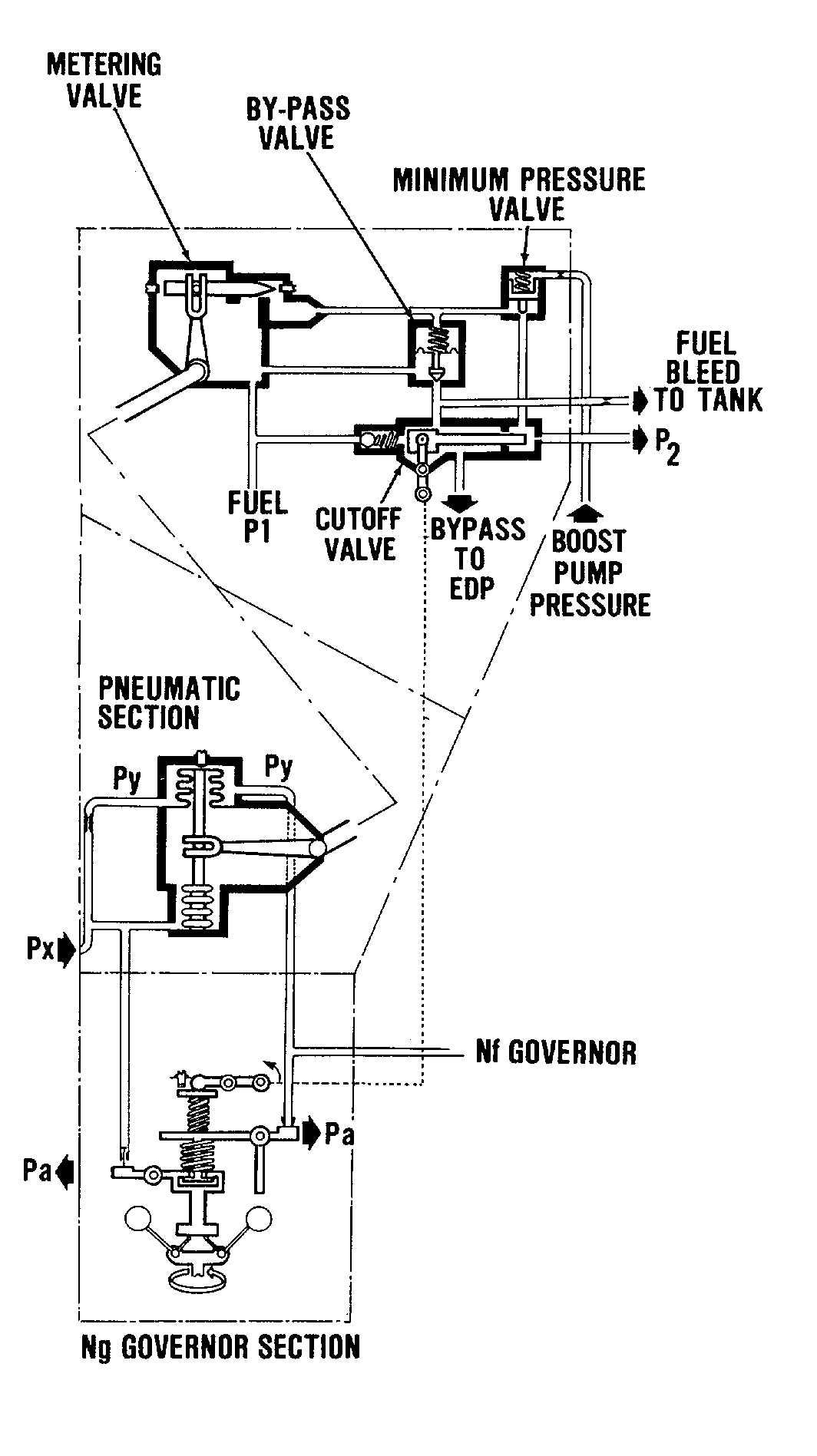

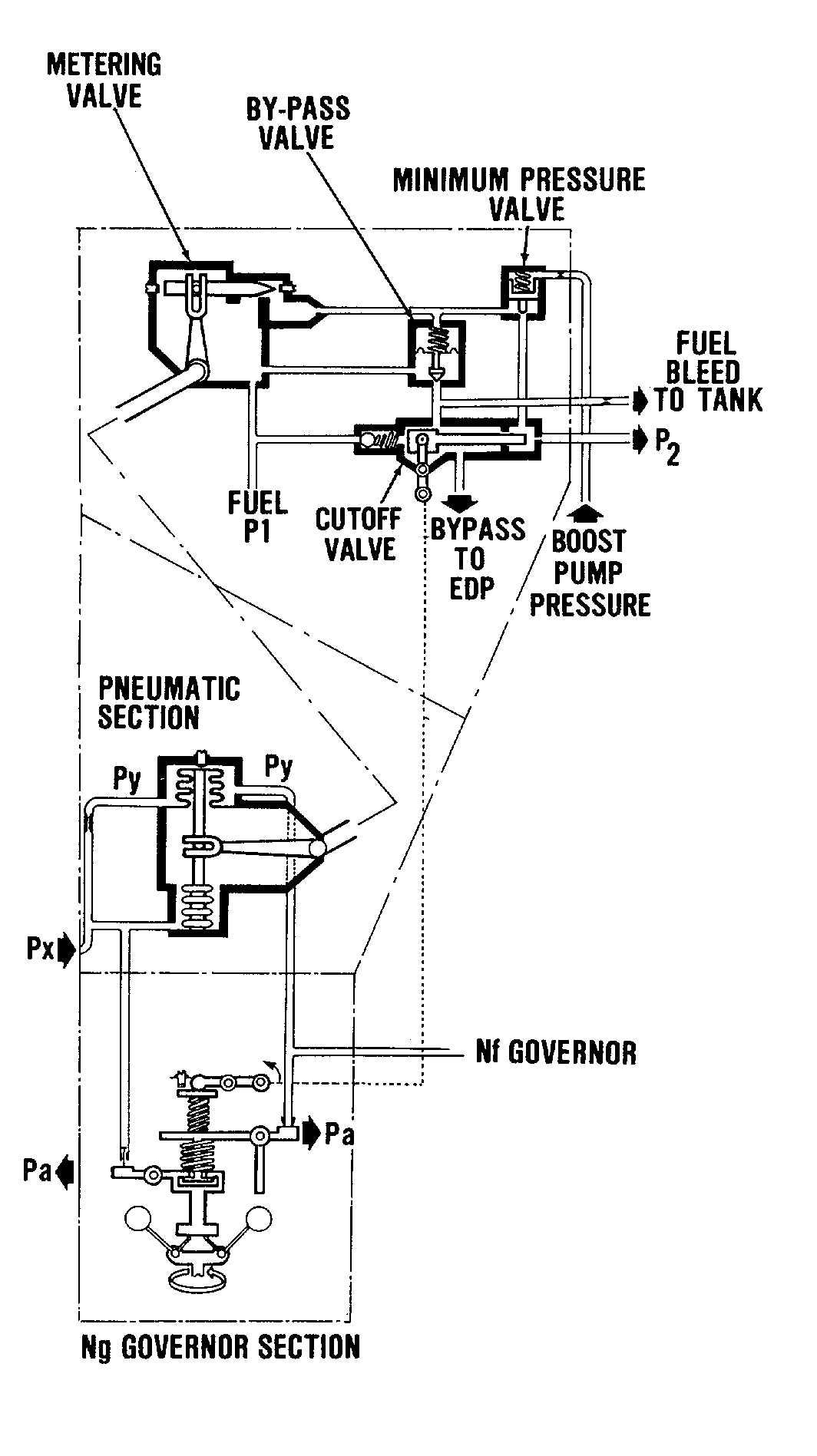

Fuel Control Unit

The fuel control unit, mounted on the fuel pump,

determines the amount of fuel needed by the engine to

meet the pilot's power control lever setting. Engine

power output depends upon compressor turbine speed

(Ng), which is controlled by regulating the amount of fuel

supplied to the fuel manifold assembly nozzles.

Fuel under pressure (P1) is supplied to the metering

valve, which controls the flow of fuel to the engine at

pressure (P2). The bypass valve maintains a steady

P1- P2 differential to enable the metering valve to meet

varying power demands. A minimum pressure valve

insures enough pressure at the fuel nozzles to obtain a

correct spray pattern.

The Ng governor is driven at a speed proportional to Ng,

thus any change in Ng causes the centrifugal weights to

move to open or close valves, changing the pressure

balance of the bellows in the pneumatic section.

Bellows movement is mechanically linked to the

metering valve, thus altering the fuel supply to the fuel

nozzles. Air (Px) to the pneumatic section comes from

the gas generator via the temperature compensator.

GO TO NEXT PAGE

1-13