TM 1-1500-204-23-1

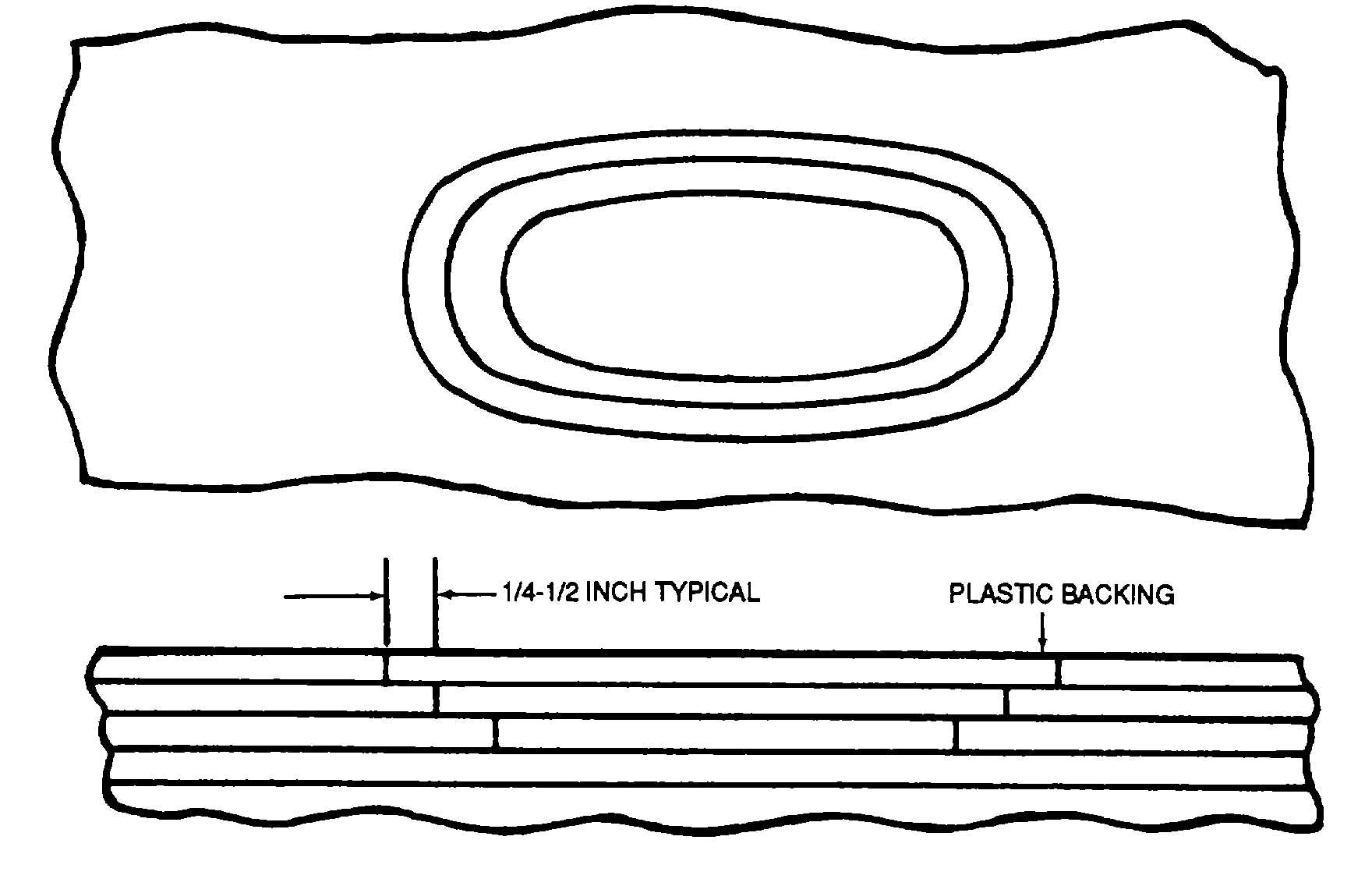

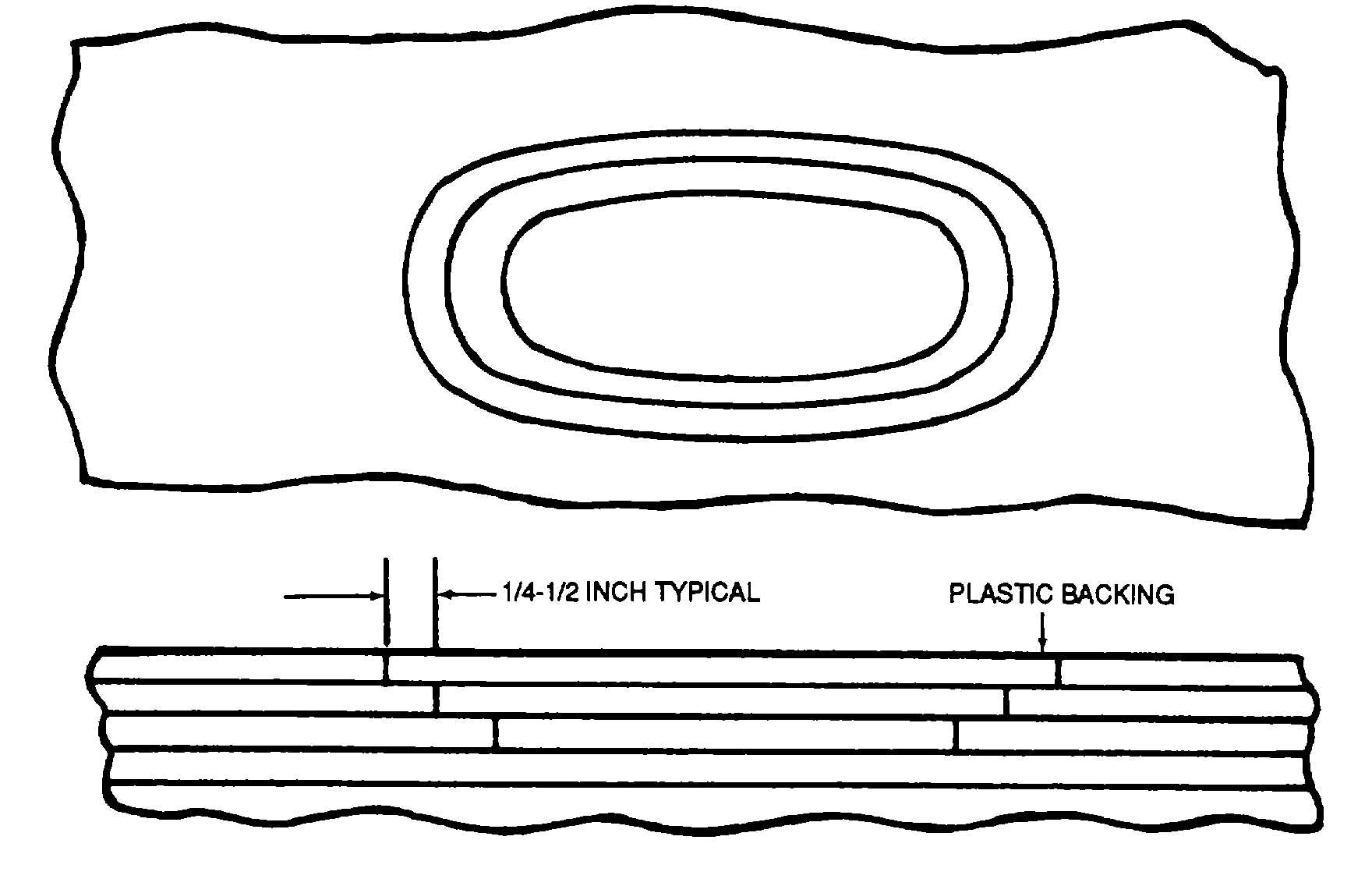

Figure 9-39. Gouge Repair

(m)

Sand smooth all repaired areas

after curing using No. 320-400 grit abrasive cloth.

(7)

Repair and inspection of threaded inserts

in backing. Repair and inspection procedures are as

follows:

(a)

Inspect panel for loose inserts

or damaged threads.

NOTE

Inserts in a composite fiberglass-

plastic type of backing have a

tendency to work loose. It is

important to replace any missing

insert as the heavy armor panels are

severely strained during a shock

loading, such as a hard landing.

(b)

Repair damaged Insert threads,

where possible, using the proper sized tap to chase

threads.

(c)

Where an insert is loose, drill

two small holes, 180 degrees apart, in the fiberglass

backing next to the insert Angle the holes toward the

bottom of the insert.

(d)

Inject bonding compound, Metalset

A4 (FSCM 90414)with a syringe into one hole. Fill

around insert until compound discharges from second

hole.

NOTE

Metalset A4 resin cement is furnished

as two compounds, Part A (resin) and

Part B (hardener). Thoroughly mix

Part A and Part B in a 1 to 1 ratio by

weight or volume. Allow bonding

compound

to

cure

at

room

temperature

for

24

hours.

For

accelerated

curing

cure

bonding

compound at 150°F (660C) for two

hours. Excess Metalset A4 must be

removed before it hardens. Remove

excess resin with Toluol, TT-T-548.

(e)

Replace rubber edge molding

after abrading the inside surface using a fine wire wheel

(0.004 inch diameter wire) or abrasive cloth.

9-56