TM 1-1500-204-23-1

(2)

Move equipment to extreme positions in

every direction to ensure that retaining fasteners are

secure and the isolators have not sagged.

NOTE

Prior to any attempt to install

vibration isolators, the high, or low

side, must be found. Each Isolator

has a low side and a high, or load

side. In some instances, the words

LOAD SIDE will be stamped in the

high side of the isolator to facilitate

identification.

c.

Inspection of Vibration Isolators. To prevent

unsatisfactory isolation and eliminate damage, vibration

isolators shall be inspected and replaced in accordance

with the applicable phase maintenance inspection

checklist. The following are general inspection

procedures for all types of vibration isolators.

(1)

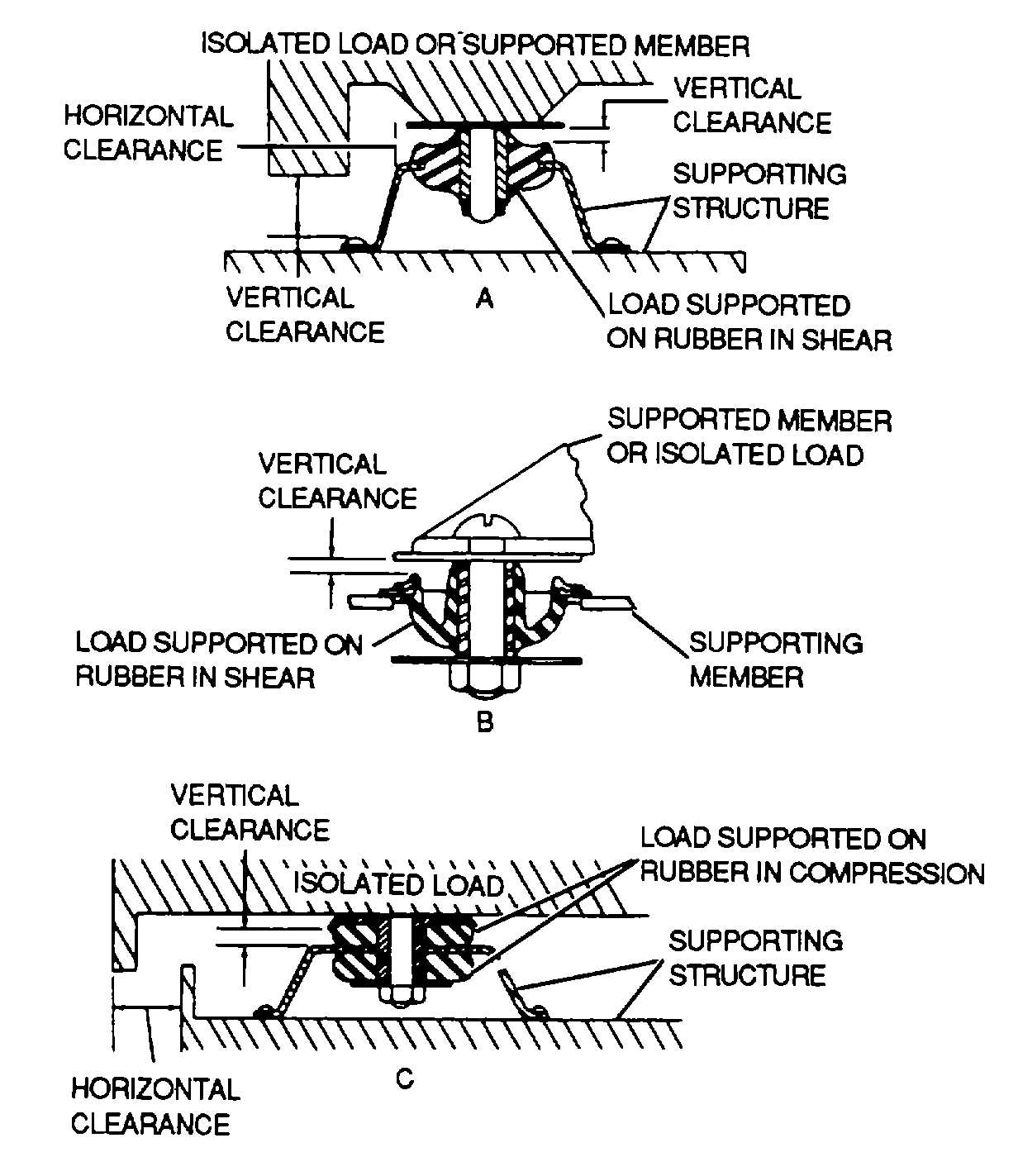

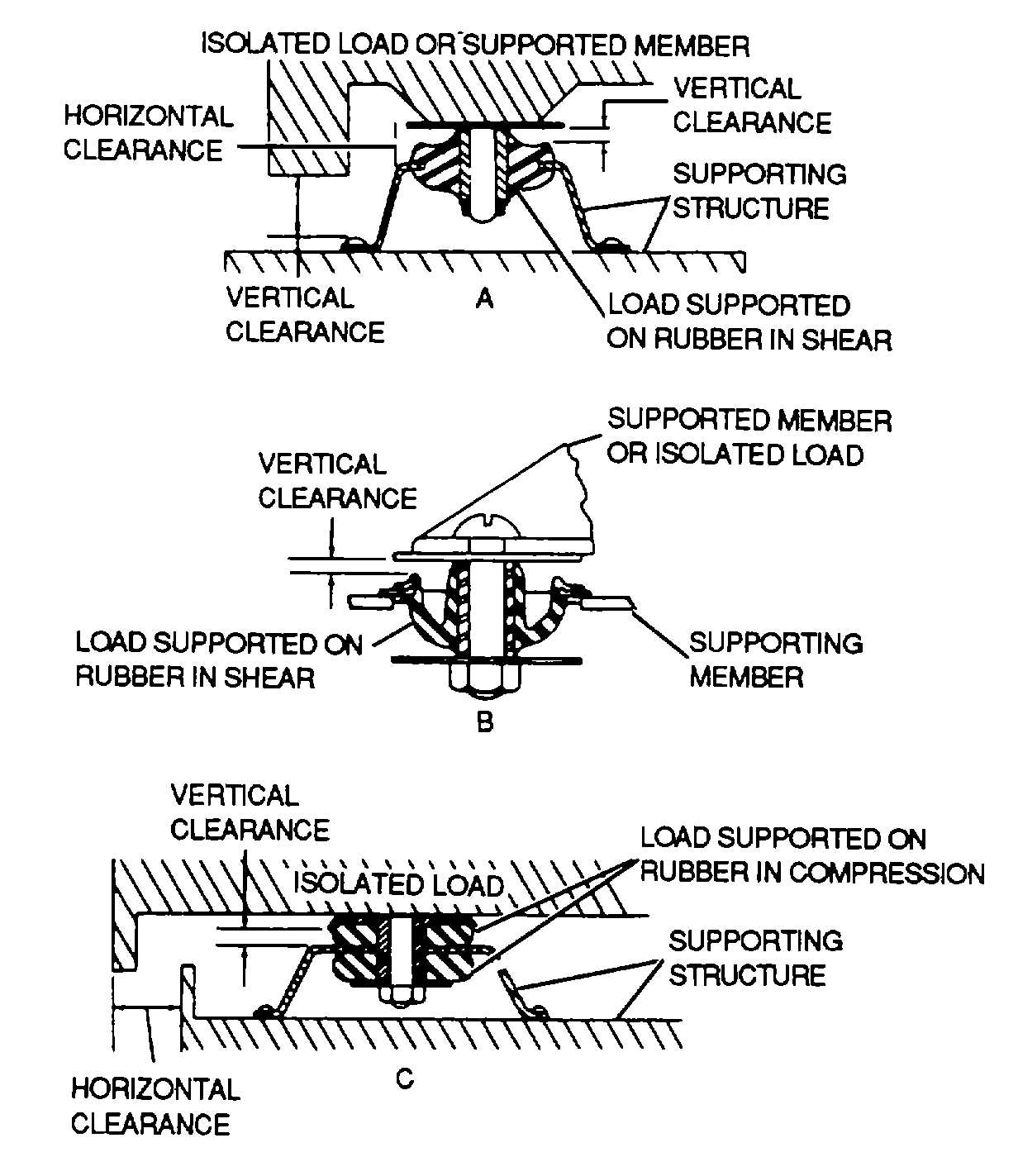

Using a standard thickness gauge or 6

inch scale, measure vertical and horizontal clearance

between isolated load (equipment case, mounting base,

or instrument panel), and nearest support structure

(isolator mounting cup, mounting base, or aircraft

structure) with vibration isolators with any vertical or

horizontal clearances of less than 1/16 inch.

(2)

Move equipment or instrument panel to

extreme positions in every direction to determine if

Isolators have sagged, or retaining rivets or holddown

screws are loose

(a)

When elastic rubber parts of open-

type vibration isolators are stretched to their extreme

position, examine rubber for cracks, or separation of

rubber to metal bond. Replace isolators with any of

these conditions visible.

(b)

When

equipment

on

combined

vibration isolator mounting base is moved to extreme

positions in all directions, examine sponge rubber or

metal mesh pads for deterioration and permanent

packing. Replace vibration Isolators with cracked or

deformed pads which seriously affect isolation efficiency

of mounting system.

Figure 9-40. Open-Type Vibration Isolators

9-58