TM 1-1500-204-23-1

pattern uniformity on like items of equipment, painting

and highlighting shall be accomplished in accordance

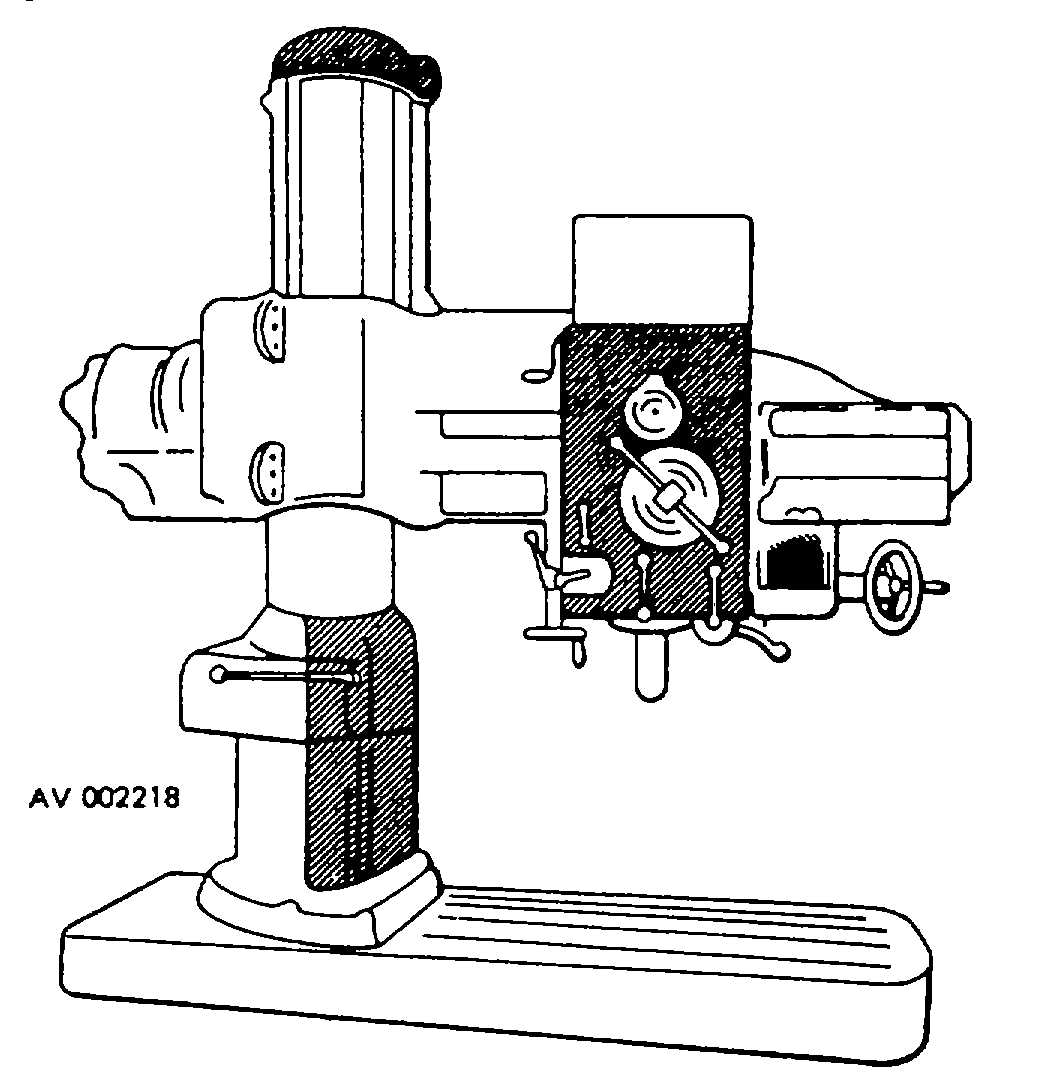

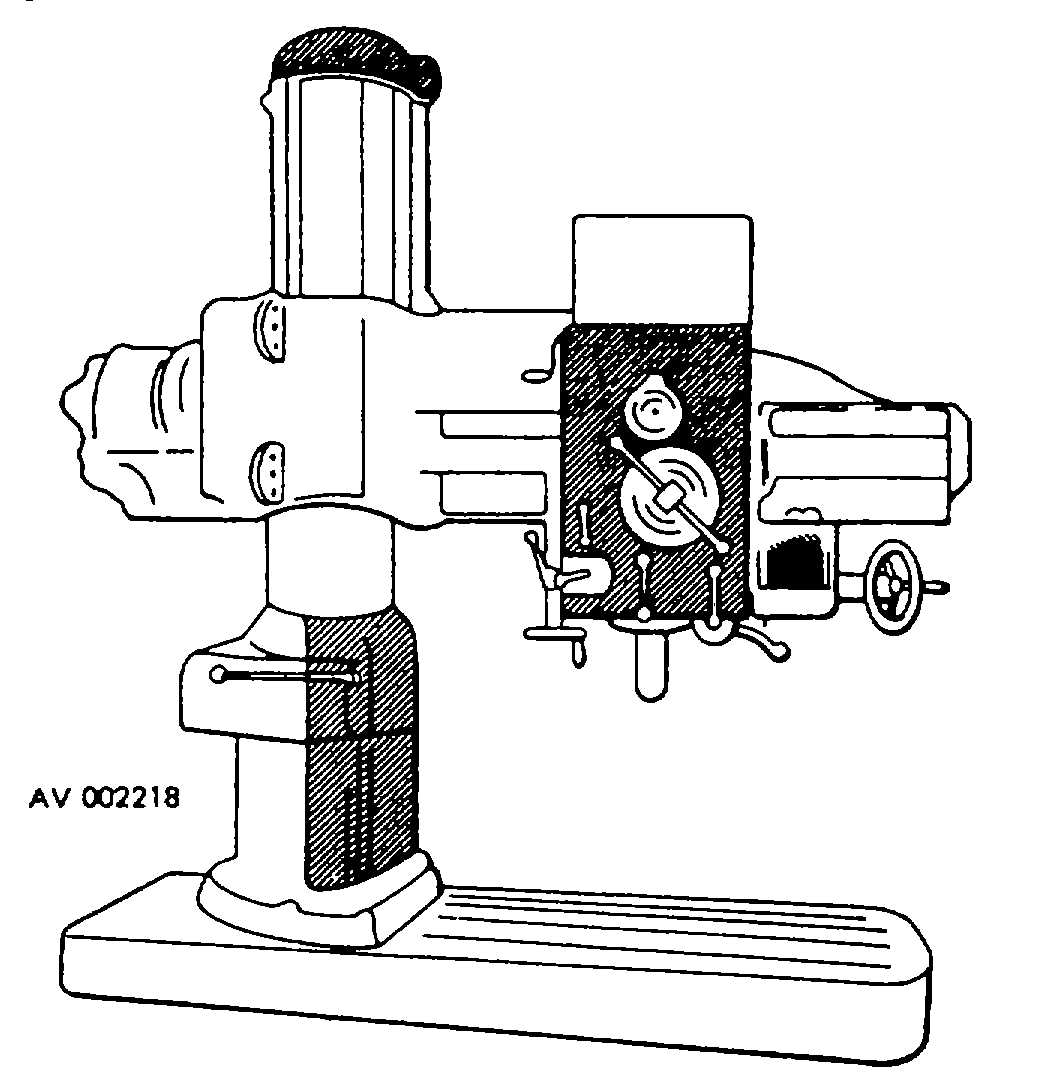

with the general pattern shown in figure 2-2. Equipment

other than the type illustrated, shall be painted in

accordance with these general instructions. The painted

finish on this equipment may be retouched. The

commanding officer or his designated representative

shall determine the extent of the touchup allowed

without complete repainting.

(3)

Natural wood pieces. Wood pieces or

equipment finished in colors other than those listed in

paragraph 2-4c may be touched up with colors to match

existing finish, provided touchup does not involve

refinishing a total area equal to more than 10 percent of

painted surface area. When more than 10 percent of

painted surface area must be touched up, item shall be

repainted with colors as specified.

NOTE

Instrument repair benches or other

special purpose benches, parts, and

equipment

having

natural

wood

finish may be refinished in natural

wood

or

white

enamel,

Federal

Specification TT-E-489, color shade

17875. Working surfaces of bench

tops

covered

with

metal

or

composition need not be repaired.

(4)

Start buttons. Start buttons shall be painted

with Federal Specification TT-E-489, green synthetic

gloss enamel, color shade 14260.

Figure 2-2. Painting of Shop Equipment to

Highlight Operator Position.

(5)

Stop buttons. Stop buttons for electrical

switches used for emergency stopping of machinery

shall be painted with red synthetic gloss enamel,

Federal Specification TT-E-489, color shade 11105.

(6)

Hazardous areas. On some equipment,

extremely hazardous conditions may exist, such as open

flywheels, gears, or other moving parts which cannot be

guarded or which might be impractical to guard. These

parts may be painted with Federal Specification TT-E-

489, orange synthetic gloss enamel, color shade 12197.

Overuse of orange color will defeat the intended

purpose, therefore, the local safety engineer shall

determine the use of this color and furnish instructions.

Painting of machined parts, such as face plates, chucks,

spindels, etc, is not authorized.

(7)

Preparation for painting. Prepare surfaces to be

repainted using the following procedures:

(a)

Surface should be clean, dry, and free

from dust, grease, oil, rust, and dirt. Glossy surfaces

should be sanded to dull the gloss to ensure adhesion .

Remove all rust and scale by scraping or wire brushing.

WARNING

Under

no

circumstances

shall

flammable material be used near an

open flame. Otherwise injury or

death may result to personnel.

(b)

Remove oil and grease deposits from

machinery to be repainted with kerosene, ASTM D3699.

WARNING

Drycleaning solvent is flammable

and solvent vapors are toxic. Use P-

D-680, Type II Solvent in a well-

ventilated area. Keep away from

open flames. Avoid prolonged

solvent contact with skin.

(c)

Wipe surface with a clean cloth moistened

with a grease-free solvent, such as drycleaning solvent,

Federal Specification P-D-680, or paint thinner, Federal

Specification TT-T-291. Repeat this procedure until

machinery surfaces are completely clean.

(d)

Bare spots resulting from scraping or

chipping should be sanded to a feather edge and spot

primed with lacquer proof primer, Federal Specification

TT-P-664. Allow priming coats to dry thoroughly and

apply two coats of enamel, Federal Specification TT-E-

489, in prescribed colors.

2-5