TM 1-1500-204-23-2

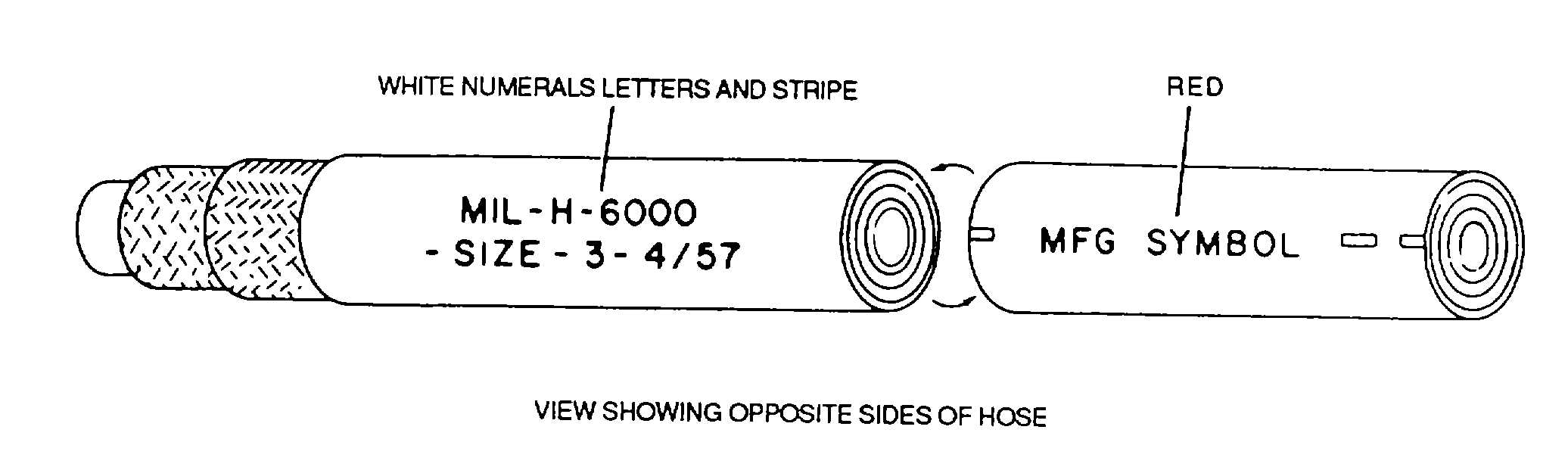

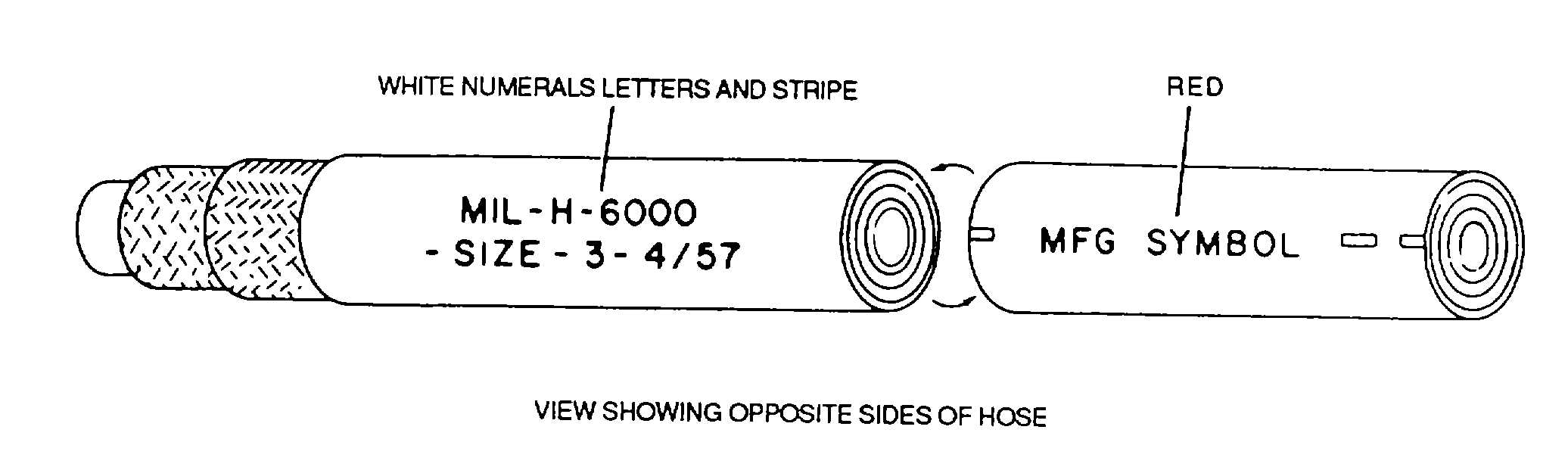

Figure 4-35. Nonself-Sealing, Aromatic and Heat-Resistant Hose, MIL-H-6000

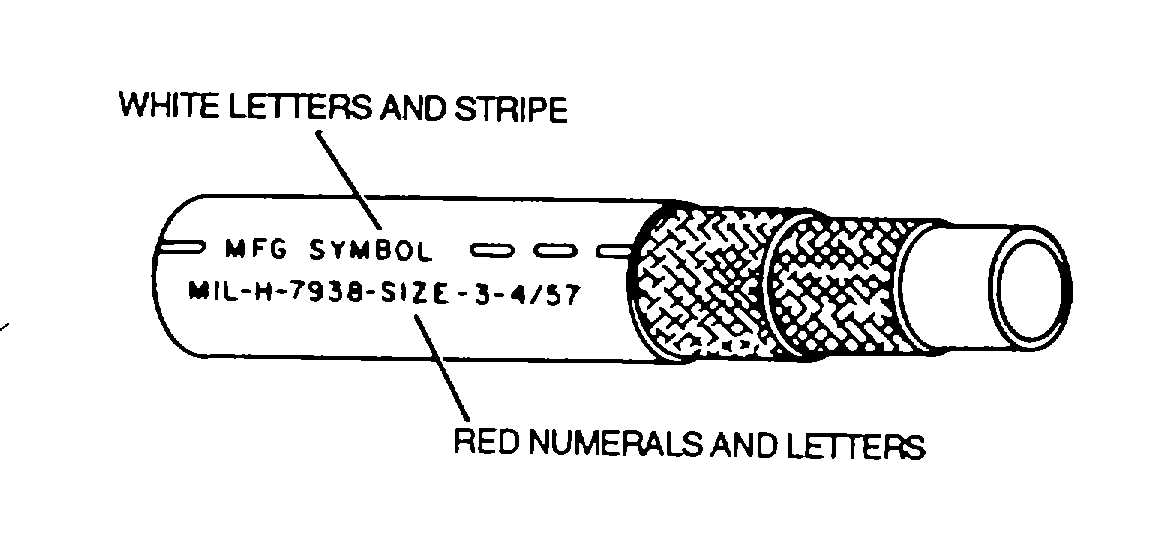

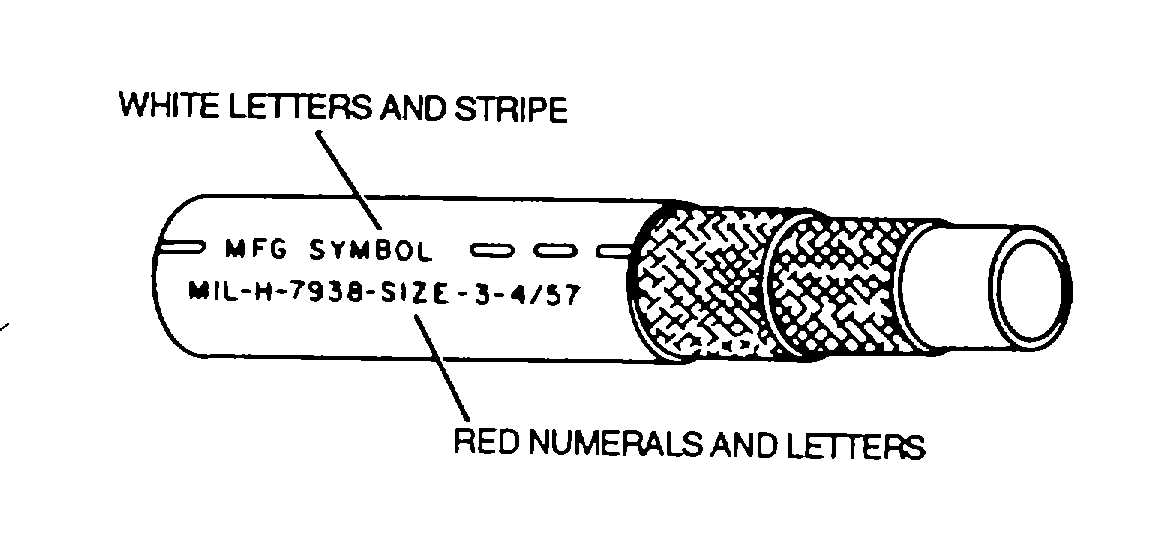

Figure 4-36. Flame Aromatic, and Oil-Resistant

Hose MIL-H-7938

NOTE

Whenever operating pressure of a hose as-

sembly is unknown, it will be assumed to be

1500 psi or greater

(a) Below30psi. For hose assemblies used

as vents and hose assemblies which operate below 30

psi, excessive wire damage as described herein will not

apply. Replacement of these assemblies will be at the

discretion of the local inspector/mechanic using good

shop practice and experience.

(b) Below 500 psi. For hose assemblies

which operate below 500 psi, excessive wire damage

consists of four or more broken wires In a single plait,

12 or more broken wires per assembly or per lineal foot

whenever assemblies exceed 12 inches in length.

(c) Above 500 psi. For hose assemblies

which operate at 500 psi and above, excessive wire

damage consists of two or more broken wires In a single

plait, two or more adjacent wires, one or more broken

wires in an area where kinking is suspected, six or more

broken wires per assembly or per lineal foot whenever

assemblies exceed 12 inches. Crossed reinforcing or

random broken wires are not causes for rejection.

(5) Leakage. Hose assemblies will be replaced

when leakage occurs with hydraulic pressure applied.

(6) Static leakage. With no pressure applied,

leakage exceeding one drop per hour will be cause for

replacement of the assembly.

(7) Abrasion, kinking, distortion, bulging, col-

lapse, or sharp bending. Any evidence of these con-

ditions will require replacement of hose assemblies

NOTE

Hoses need to be changed for abrasion only

If the metal reinforcement is exposed (this

note does not apply to braided wire covered

hoses).

(8) Internal damage. Inspect internal restric-

tin due to collapse, wire braid puncture, or other

damage by one of the following methods.

4-37