TM 1-1500-204-23-2

f.

Proof Testing of Flexible Hose Assemblies. All field fabricated hose assemblies which have passed the

visual inspection shall be proof tested. Hose assemblies drawn from stock shall be inspected for defects such as

mishandling damage and proper banding and proof tested if necessary (refer to tables 4-16, 4-17, 4-18, and 4-19).

(1)

Test hose assemblies to be used in hydraulic, pneumatic, fuel, oil, and coolant applications using a

hydrostatic test unit filled with hydraulic fluid conforming to MIL-H-5606 for MIL-H-6083, lubricating oil MIL-L-6082, or

water.

(2)

Test hose assemblies to be used in instrument applications using dry, oil-free air or nitrogen, Federal

Specifications BB-N-411, Grade A, Type 1.

(3)

Connect hose assembly to be tested to hydrostatic test unit, air supply, or nitrogen supply as

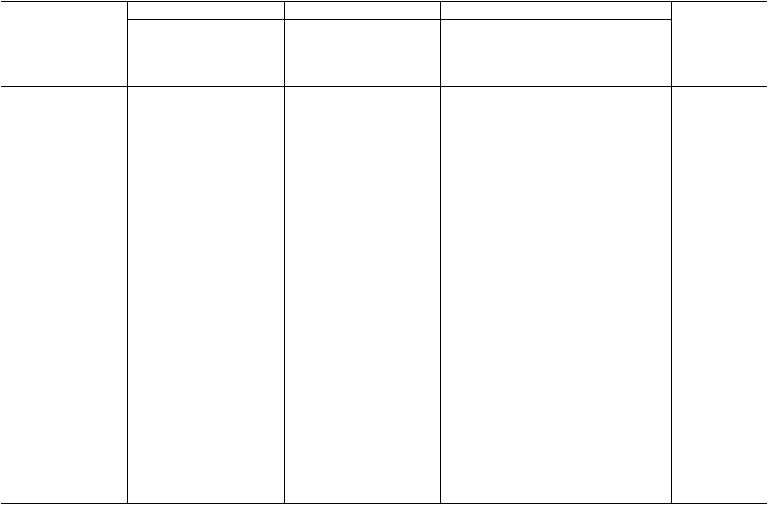

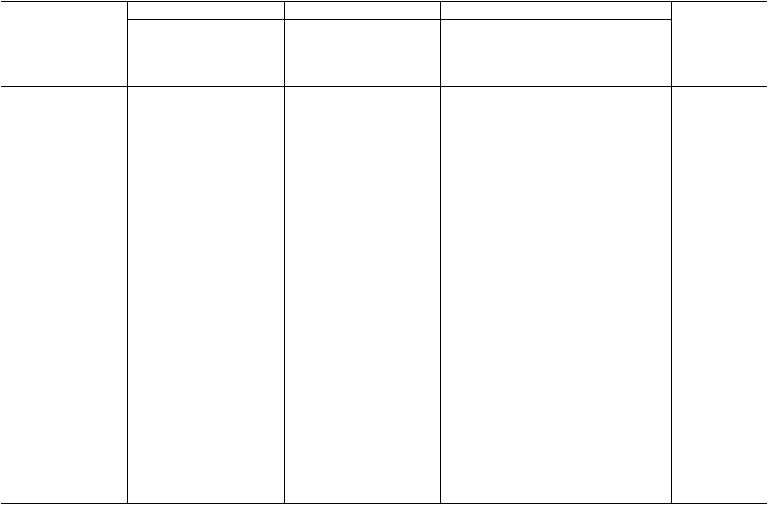

Table 4-16. Operating, Proof, and Burst Test Pressures for MS28741 Medium Pressure Hose Assemblies, using

Single Wire Braid Hose, Military Specification MIL-H-8794

Hydraulic

Fuel

Oil

Operating

Proof

Operating

Proof

Operating

Surge

Proof

Burst

Tube OD

pressure

pressure

pressure

pressure

pressure

pressure

pressure

pressure

Size

(inches)

(psi)

(psi)1

(psi)

(psi)1

(psi)

(psi)

(psi)1

(psi)

-3

3/16

3000

6000

1000

1500

50

400

600

12,000

-4

1/4

3000

6000

1000

1500

50

400

600

12,000

-5

5/16

3000

5000

1000

1500

50

400

600

10,000

-6

3/8

2000

4500

1000

1500

50

400

600

9000

-8

1/2

2000

4000

1000

1500

50

400

600

8000

-10

5/8

1750

3500

1000

1500

50

400

600

7000

-12

3/4

1500

3000

1000

1500

50

400

600

6000

-16

1

800

1600

750

1000

50

400

600

3200

-20

1-1/4

600

1250

500

750

50

400

600

2500

-24

1-1/2

500

1000

250

375

50

400

600

2000

-32

2

350

700

200

300

50

400

600

1400

-40

2-1/2

200

300

1000

-48

3

200

300

800

1

Hold proof-test pressure for not less than 30 seconds nor more than 5 minutes.

4-48