TM 1-1500-204-23-2

NOTE

Do not overtighten vise on thin-walled sockets of lightweight fittings Outer cover of hose is not stripped

(b)

Tighten nipple and nut on appropriate assembly tool from Aeroquip kit, part number S-1051.

(c)

Lubricate nipple threads and inside of hose liberally using a light minor oil or hydraulic fluid, MIL-

H-5606.

(d)

Screw nipple into socket and hose using a wrench on nipple hex nut. Nut must swivel freely

when assembly tool is removed. Maximum allowable gap between socket and nut or nipple hex is 1/16 inch

(6)

Inspect hose assembly internally for cut or bulged Inner tube, obstructions, and cleanliness See figure

4-44 for minimum bulge diameter clearances. Inspect for proper gap between nut or nipple hex and socket

WARNING

Make no adjustment, under any condition, of assembly gap or position angle after test and final

acceptance of complete hose assembly. Failure to comply may compromise the integrity of the hose

assembly.

NOTE

The measurement of the bulging of hose inner tubes caused by attachment of the fitting shall be made

with a ball-end type gauge. The diameter of the ball shall be within 0. 001 Inch of the minimum bulge

diameter. The weight of each gauge In ounces shall be equal to the dash number of the fitting being

tested. In taking the measurement, the gauge shall be placed inside the end of the assembly without

lubrication, and without pushing through. The gauge shall fall through the bulge under its own weight.

This test shall be made only on straight fittings.

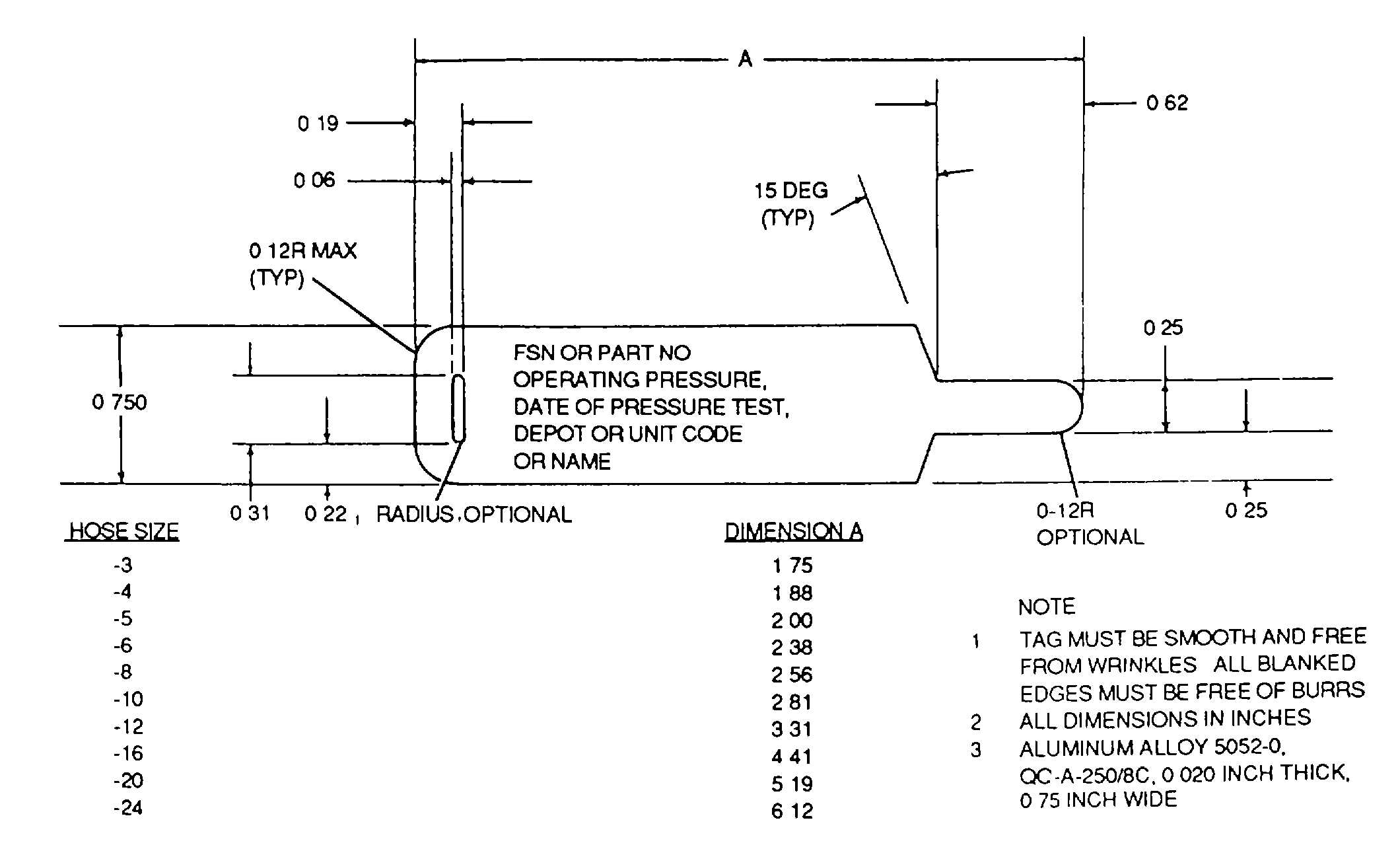

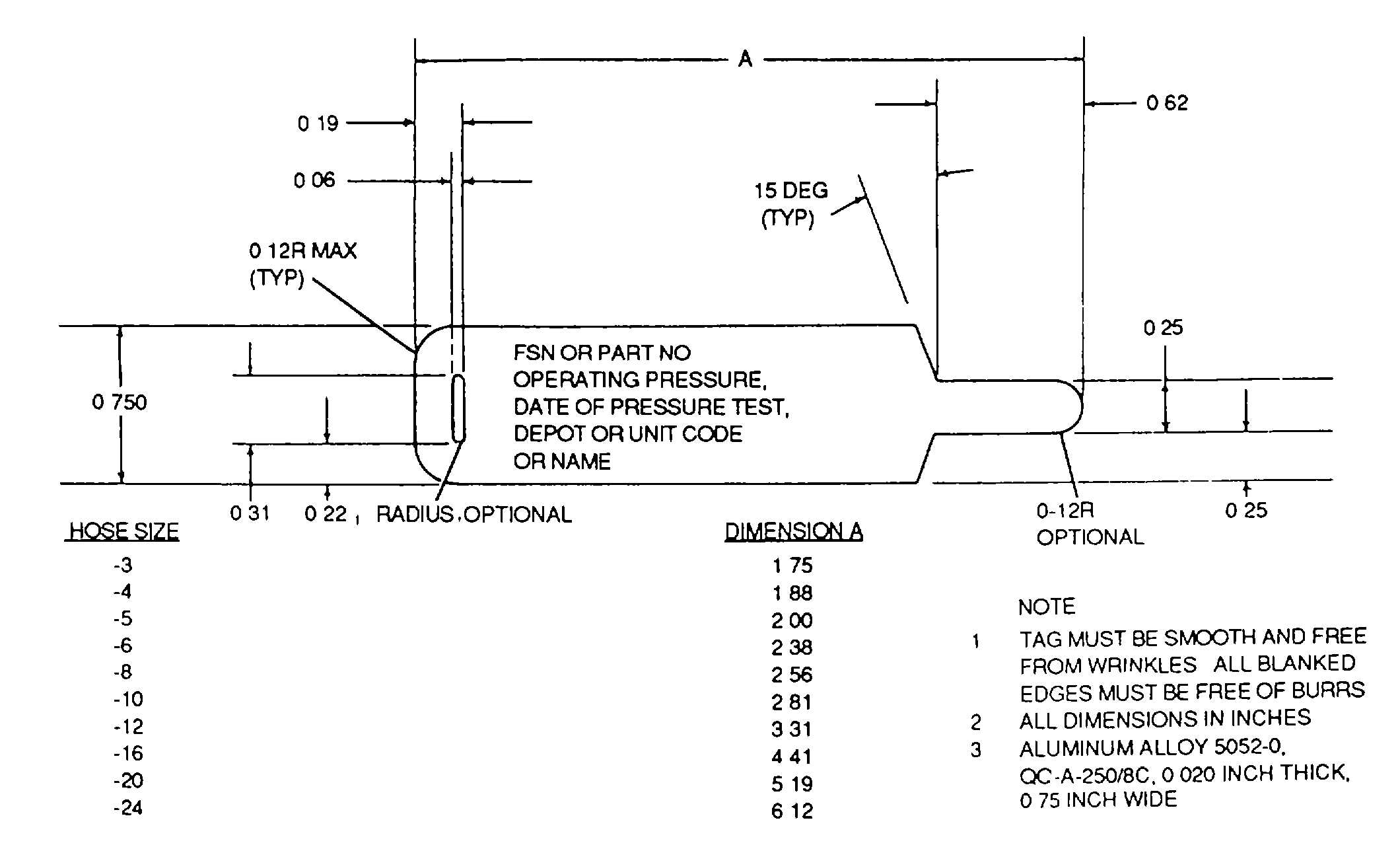

Figure 4-42. Identification Tags for Field Fabricated Hose Assemblies

4-53