TM 1-1500-204-23-4

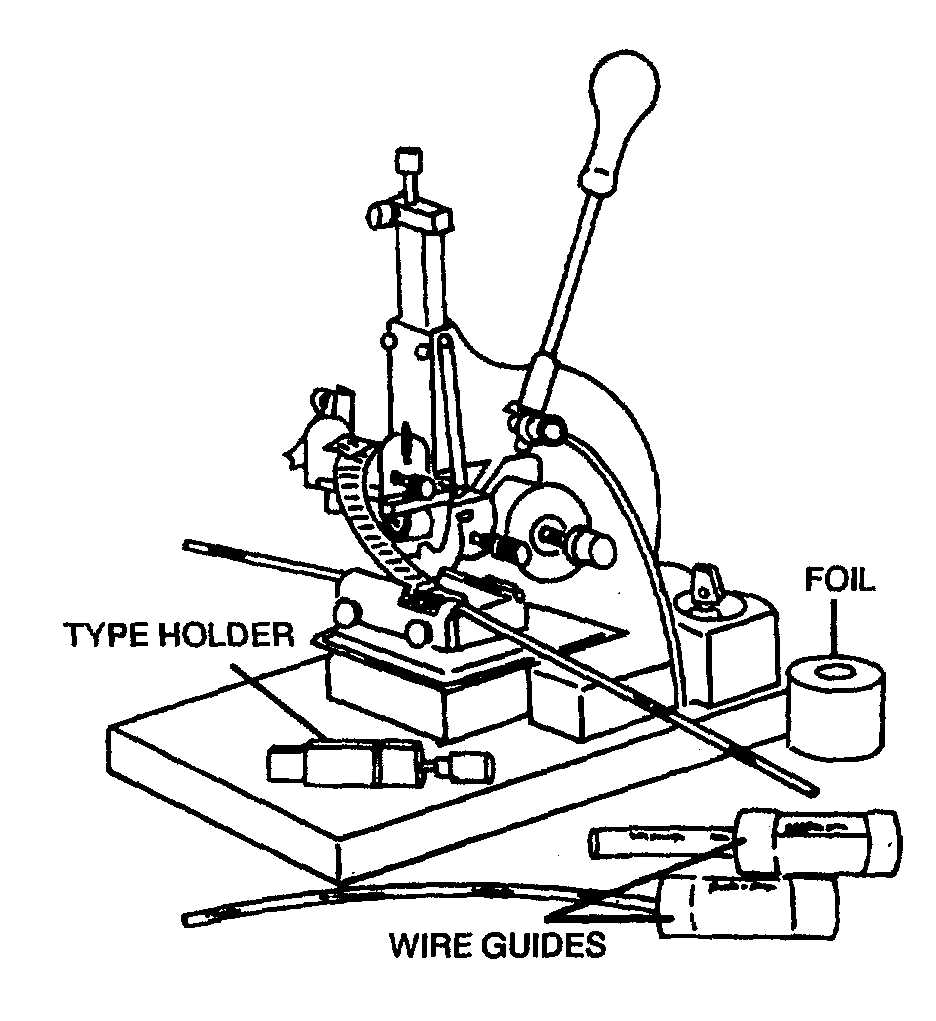

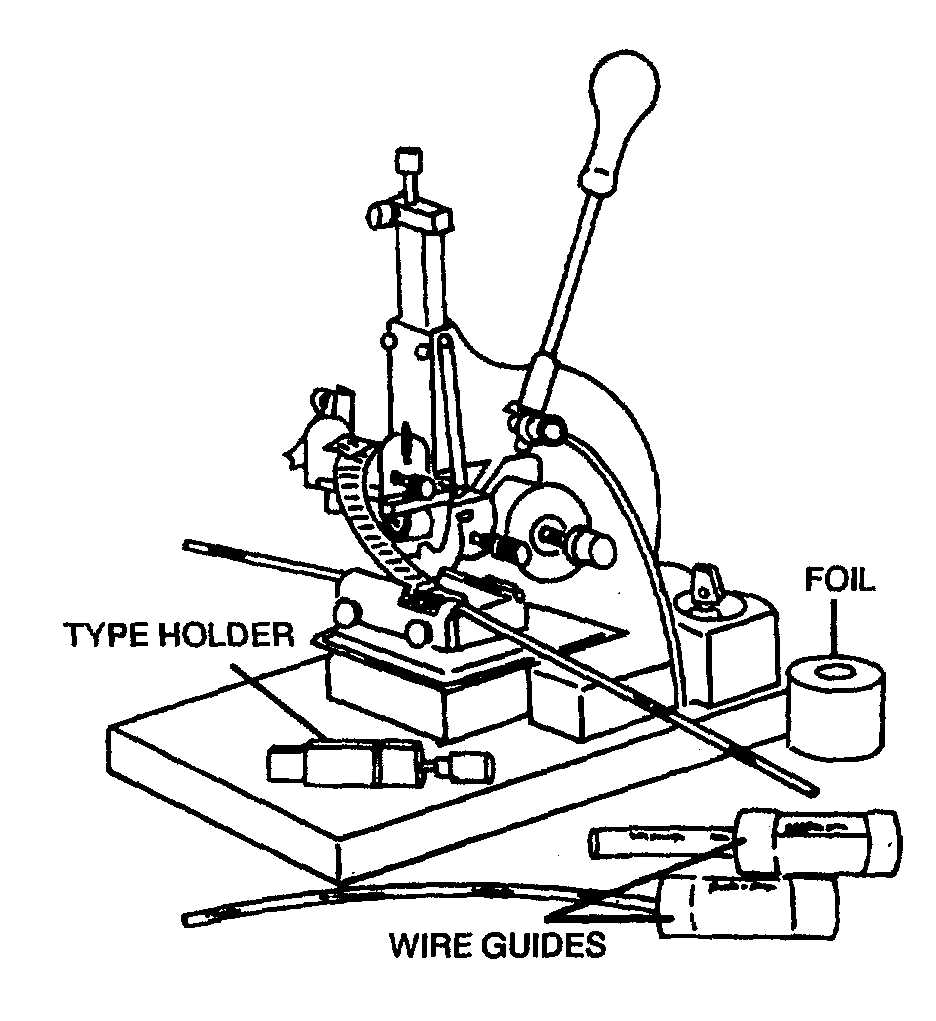

Figure 3-3. Hand Wire Marking Machine

Table 3-2. Recommended Sizes of Marking Type

Height of letters

Wire size

(Inches)

No. 26 and No. 22

1/16

No. 20 thru No. 14

5/64

No. 12 thru No. 0000 and

7/64

Coaxial Cable

(2)

Ensure

terminal

blocks

are

securely

mounted.

(3)

Ensure terminal connections to terminal

block studs, and nuts on unused studs, are tight.

(4)

Ensure

evidence

of

overheating

and

corrosion is not present on connections to terminal block

studs.

(5)

Ensure the number of terminal connections

to a terminal block stud does not exceed four.

(6)

Inspect for physical damage to studs, stud

threads, and terminal blocks. Replace cracked terminal

strips and those studs with stripped threads.

h.

Fuses and Fuse Holders. When installing fuses

and fuse holders, inspect using the following procedures:

(1)

Inspect for security of connections to fuse

holders.

(2)

Inspect for the presence of corrosion and

evidence of overheating on fuses and fuse holders.

Replace corroded fuses and clean fuse holders. If

evidence of overheating is found, check for correct rating

of fuse.

(3)

Inspect for security of mounting of fuse

holder.

(4)

Inspect for replenishment of spare fuses

used in flight. Replace with fuses of appropriate current

rating only.

(5)

Inspect for exposed fuses susceptible to

shorting. Install cover of non-conducting material if

required.

i.

Splices. When installing crimp type connectors,

inspect splices using the following procedures:

(1)

Check for the presence of snug-fitting

transparent insulating tubing extending at least 1/2 inch

over each end and tied in place with waxed cord unless

the connector is of the pre-insulated type. Use of

transparent tape is approved, but only as a temporary

means, to be replaced as soon as possible.

(2)

Check for the spacing of splices at

staggered intervals to prevent excessive enlargement of

the bundle. Groups of non-staggered splices need not be

replaced; however, it may be necessary to use extra

damps to support the added localized weight.

NOTE

·

Splices may be used within 12

inches of a termination device

when attached to the pigtail

spare

lead

of

a

potted

termination device, or to splice

multiple wires to a single wire,

or to adjust the wire sizes so

that they are compatible with

the contact crimp barrel sizes.

·

The application of splices shall

be

design

control

and

be

authorized by the applicable

technical manual or ATCOM

engineering.

Change 3

3-6