TM 1-1500-204-234

b.

Replacement Criteria. Wiring shall be replaced

when found to have any of the following defects:

·

It becomes unmanageable due to splice or number of

splices.

·

The primary insulation has been broken.

·

The outer insulation is weather-cracked.

·

It is known to have been exposed to battery acid or

the insulation is beginning to deteriorate due to

suspected exposure to battery acid.

·

It shows evidence of overheating.

·

The insulation has been saturated with engine oil,

landing gear lubricant, hydraulic fluid, or solvent.

·

It shows evidence of having been crushed or severely

kinked.

CAUTION

Cleaning agents or preservatives

shall not be used to minimize the

effects

of

corrosion

on

or

deterioration

of

wire

shields.

Further damage may occur.

·

The metallic shield on shielded wire is frayed or

corroded.

·

The insulation sleeves placed over wire splices or

terminal lugs show evidence of breaks, cracks, dirt, or

moisture.

c.

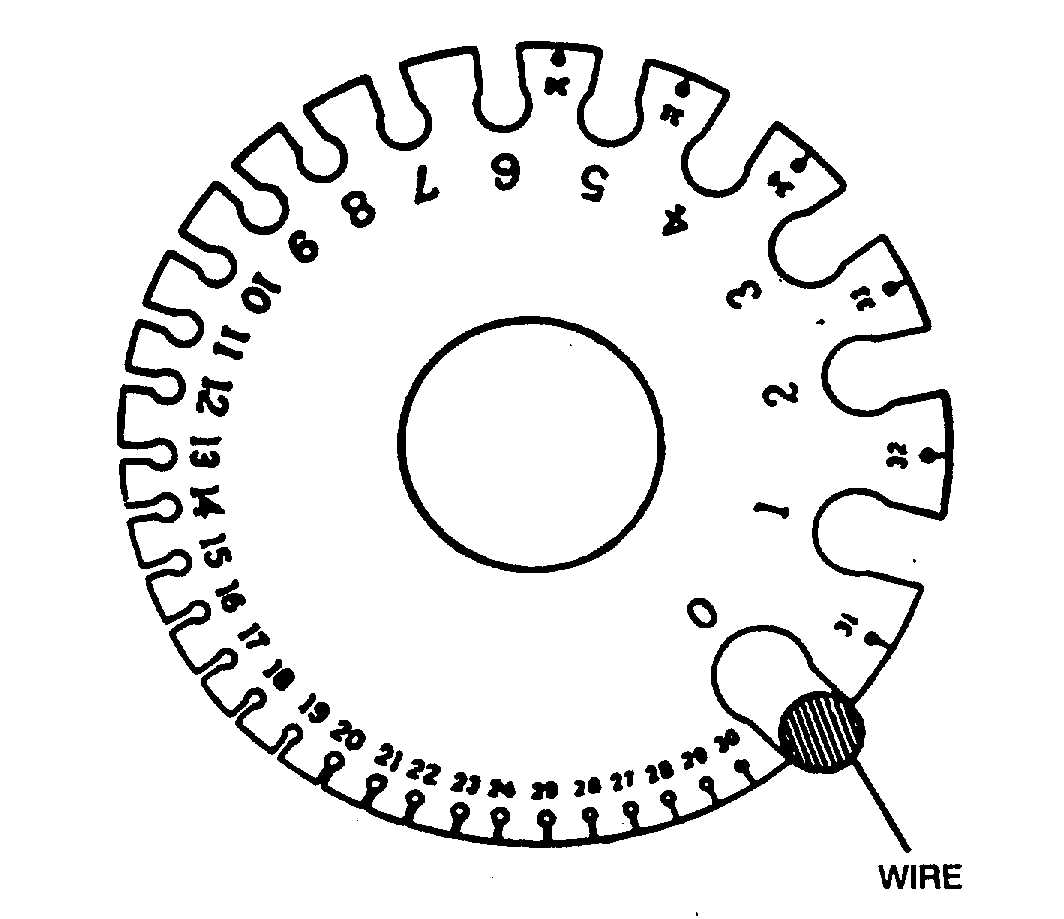

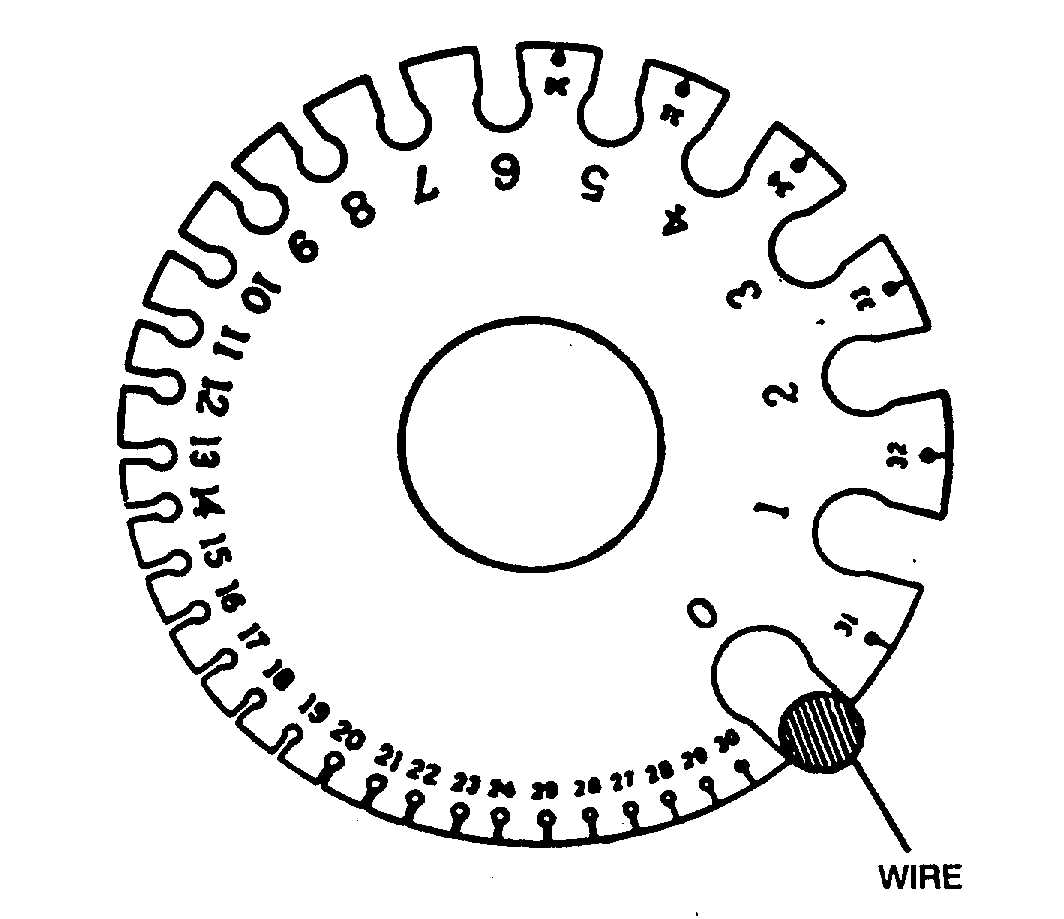

Wire Sizes. Wire is manufactured in sizes

according to a standard known as the American Wire

Gauge (AWG). Wire size may be determined by using a

wire gauge as shown in figure 3-1. This type of gauge will

measure wires ranging in size from number 0 to number

36. The wire to be measured is inserted in the smallest

slot that will just accommodate the bare wire. The gauge

number corresponding to that slot indicates the wire size.

The slot has parallel sides and should not be confused

with the semicircular opening at the end of the slot. The

opening simply permits the free movement of the wire all

the way through the slot.

Figure 3-1. Wire Gauge

NOTE

Gauge

numbers

are

useful

in

comparing the diameter of wires,

but not all types of wire or cable

can be accurately measured with a

gauge. Large wires are usually

stranded to increase their flexibility.

In such cases, the total area can be

determined by multiplying the area

of one strand (usually computed in

circular mils when diameter or

gauge number is known) by the

number of strands in the wire or

cable.

d.

Wire Identification. To make maintenance easier,

each interconnecting wire and cable installed in aircraft is

marked with a combination of letters and numbers which

identify the wire, the circuit it belongs to, its gauge size,

and other information necessary to relate the wire to a

wiring diagram. This marking is called the cable

identification code. Details of the code are given in MIL-

W-5088. Wire received from the manufacturer is printed

with the manufacturer's code designation is a light green

color at intervals of one to five feet, the MS number and

dash number of the wire, and a one-, two-, or three-digit

number indicating the color of the basic wire insulation

and the color of the stripes (if present). The color code is

as follows:

Black

0

Blue

6

Brown

1

Violet

7

Red

2

Gray

8

Orange

3

White

9

Yellow

4

(includes also

Green

5

uncolored insulations)

Change 3

3-3