TM 1-1500-204-23-4

NOTE

Lubricate only if called for by the

manufacturer's

instructions

covering the motor. Most motors

used

in

aircraft

require

no

lubrication between overhauls.

(3) Replacement criteria. Motor replacement criteria are

as follows:

·

Replace if the insulation on leads or windings is

burned, cracked, or brittle.

·

Replace when any unusual bearing or gear noises

are detected during operation.

·

Replace when commutator bars are rough, scored,

pitted, loose, high, or worn to the depth of insulating

mica between bars.

NOTE

Remove motor from aircraft when

replacing brushes.

·

Replace brushes that are cracked, broken, chipped,

unevenly worn, or worn beyond maximum wearing

depth slot.

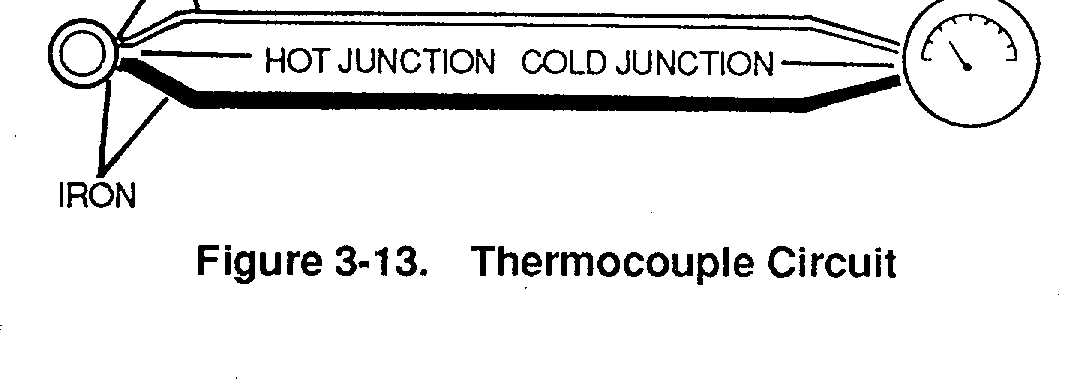

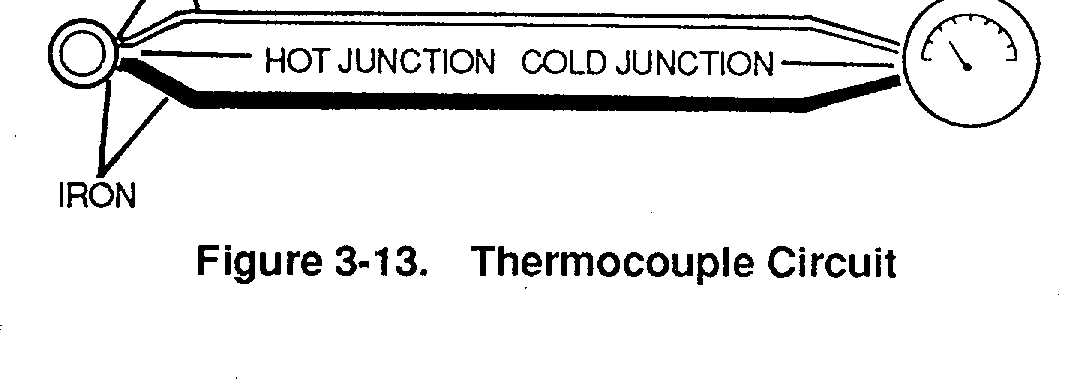

i. Thermocouples. Thermocouples are used

throughout

the

aircraft

to

detect

and

measure

temperature changes. A thermocouple, as shown in

figure 3-13, is the junction of two dissimilar metals which

generate a small electric current according to the rate of

temperature rise. Thermocouples are commonly used

in fire warning systems and temperature indicating

instruments on Army aircraft.

18

j. Ignition Systems. Ignition systems on Army

aircraft are used for engine starting and operation.

Turbine engine ignition systems are usually operated

only for a brief period during the starting cycle, during

takeoff and landing, and during flight in bad weather

(i.e., icing conditions). Turbine engines use capacitor or

electronic ignition systems.

(1) Troubleshooting. Use applicable aircraft

maintenance manuals to troubleshoot aircraft ignition

systems. Table 3-3 is an example of a typical

troubleshooting chart for an Army aircraft ignition

system.

(2)

Replacement

criteria.

Refer

to

applicable aircraft maintenance manual for replacement

criteria.

k. Lighting Systems. Army aircraft lighting

systems include cockpit lights, instrument panel and

console lights, caution and warning light systems,

position lights, anti-collision light, searchlight, and

transmission oil level lights. Instrument panel and

cockpit lighting is provided to enhance night vision of

the flight crew.

(1) Inspection. Inspect lights for corroded

lamp socket terminals, shorted or broken wires, cracked

lens, or burned out lamp bulbs.

(2) Troubleshooting. Use applicable aircraft

maintenance manuals to troubleshoot aircraft lighting

systems. Table 3-4 is an example of a typical

troubleshooting chart for an Army aircraft lighting

system.

(3) Replacement criteria. Light assembly

may be repaired by replacing damaged or defective

component parts. If light case is damaged beyond

repair, complete unit must be replaced. Replace

missing or burned out fuses, lamps, and discolored lens.

3-19