TM 1-1500-204-23-4

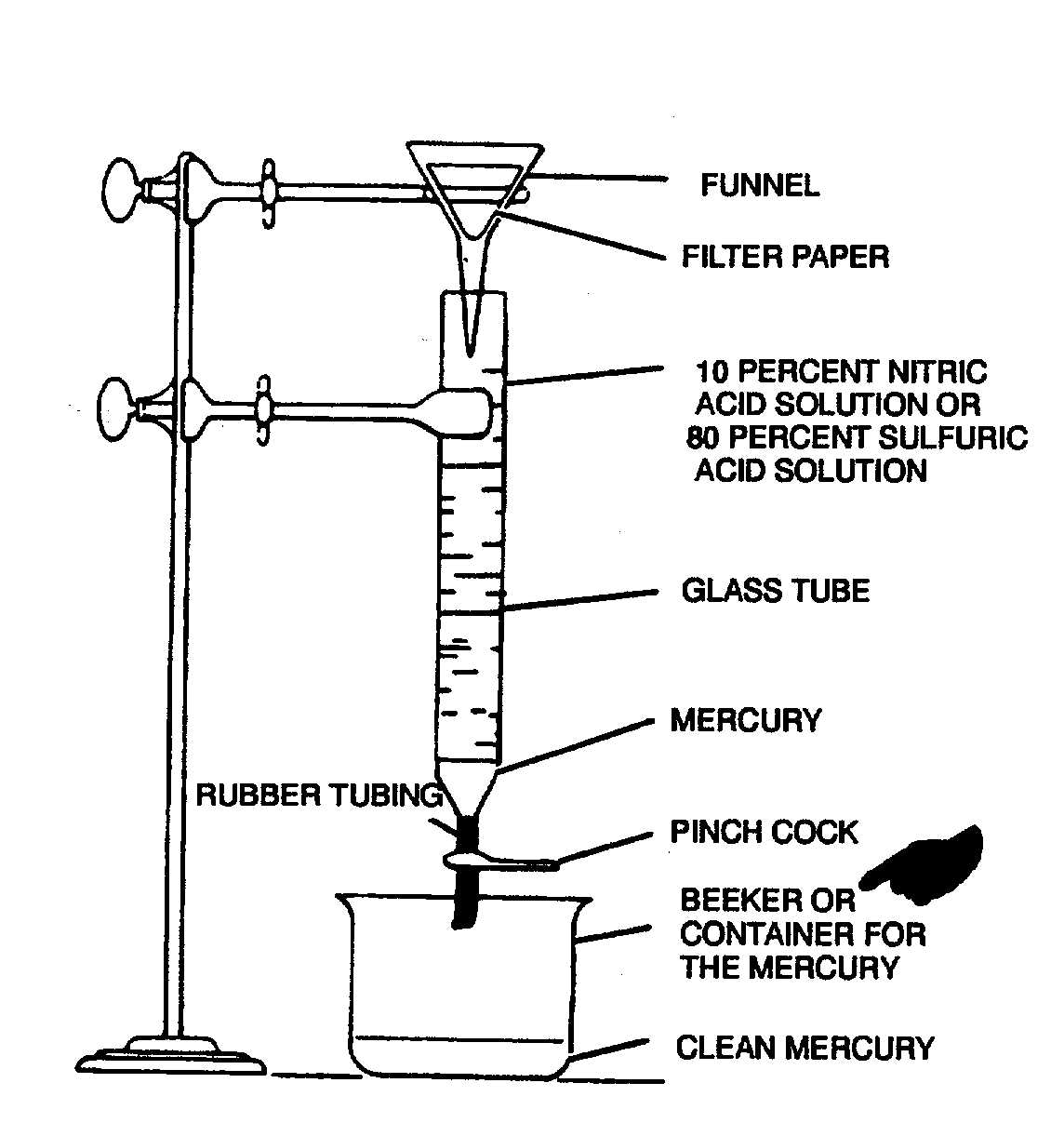

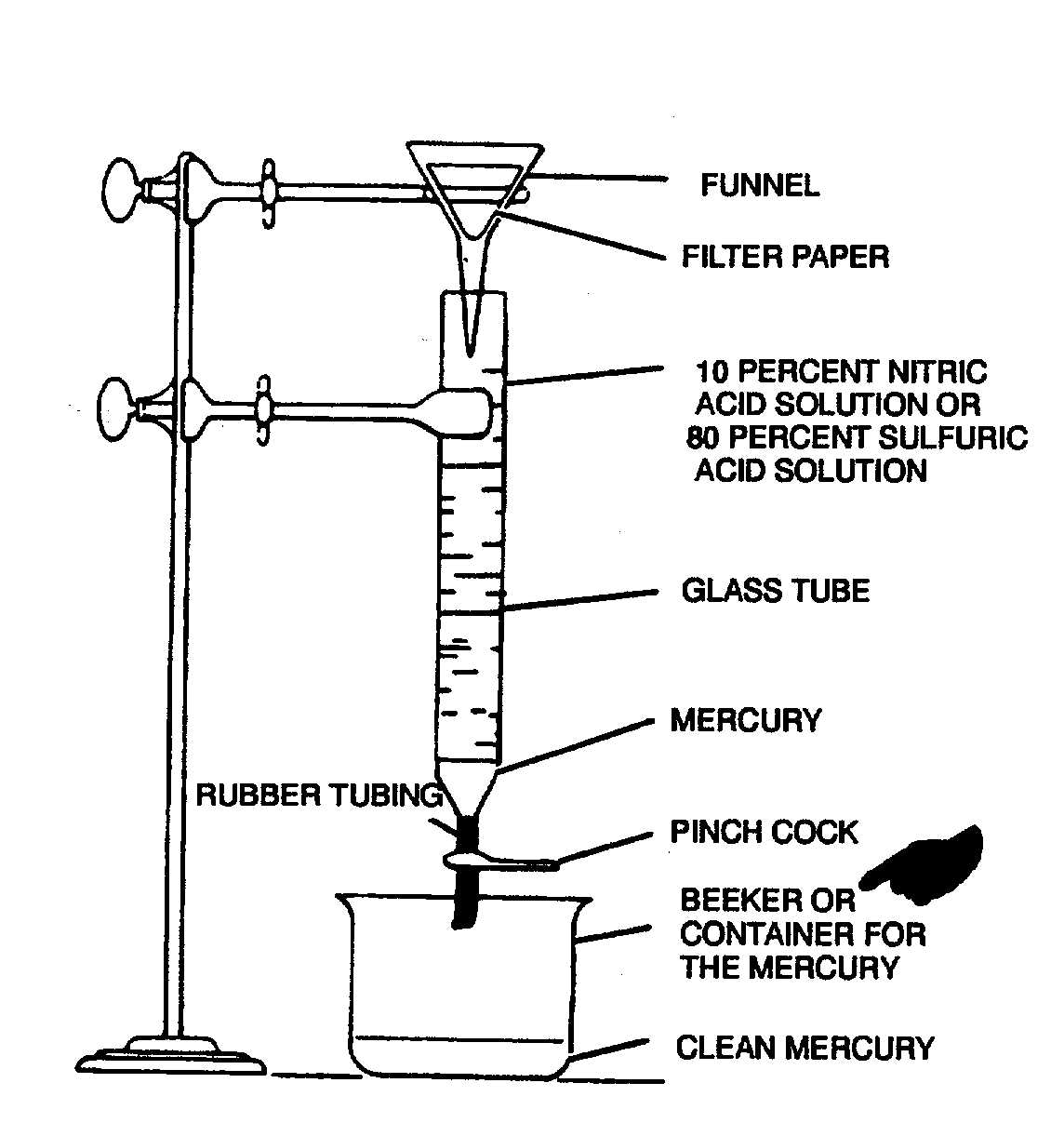

Figure 4-3. Mercury Cleaning Apparatus

tube with solution of strong soap and ammonia, Federal

Specification O-A-445.

2

Next swab tube with a solution

of nitric acid, (25 percent acid and 75 percent distilled

water).

3

Rinse cleaned tube with distilled

water and dry with ethyl alcohol, Federal Specification

O-E-760, Type II.

(3) Reservoir servicing. Fill reservoir when

required using the following procedures:

CAUTION

The fill mark is located on a plate,

or plates, near the bottom of the

manometer scale. Either a water

fill or a mercury fill plate or both

may be used. The presence of

either or both plates indicates the

materials of construction used for

parts that come in contact with

the indicating fluid and indicates

what fluids may safely be used in

the manometer. Improper fluid

may cause damage to manometer.

(a) Remove fill plug from well and

ensure drain plug is tight.

(b) Pour indicating fluid into the well

to bring level up to the fill mark designated by the fill

plate of the liquid being used.

NOTE

Keep manometer reservoirs filled

to specified level (mercury or

water). When water is used, add a

small amount of aniline dye, MIL-

A-10450 (usually red), to facilitate

quick and accurate readings.

(4) Operating procedures. With suitable

connections made and the manometer adjusted, apply

pressure (or vacuum) to the manometer and the

instrument being tested. Gradually apply the pressure

covering the entire instrument range and record

comparative readings. Refer to TM 55-6685-201-12.

(5) Safety practices. All of the cleaning

agents except water are toxic and should be used with

care.

WARNING

All except water and carbon

tetrachloride

are

highly

flammable. Use in well-ventilated

area, avoid inhalation of fumes

and skin contact. When mixing

acid and water together, always

pour the acid into the water.

Never pour water into acid. Avoid

skin contact with the acid and

with the mixture. Avoid skin

contact with the alcohol used for

a rinse. Do not drink the alcohol:

acute illness and death may

result.

(6) Mercury spill procedures. Do the

following whenever mercury is spilled:

(a) Deactivate equipment, give the

alarm, and activate exhaust systems which exhaust

room air to the outside.

(b)

Deactivate

air-conditioning

systems. Close vents and doors that would allow

mercury fumes and vapors to enter other work areas.

(c) Leave the area and take action to

assure that personnel are kept out of the contaminated

area.

Change 3 4-4