TM 1-1500-204-23-6

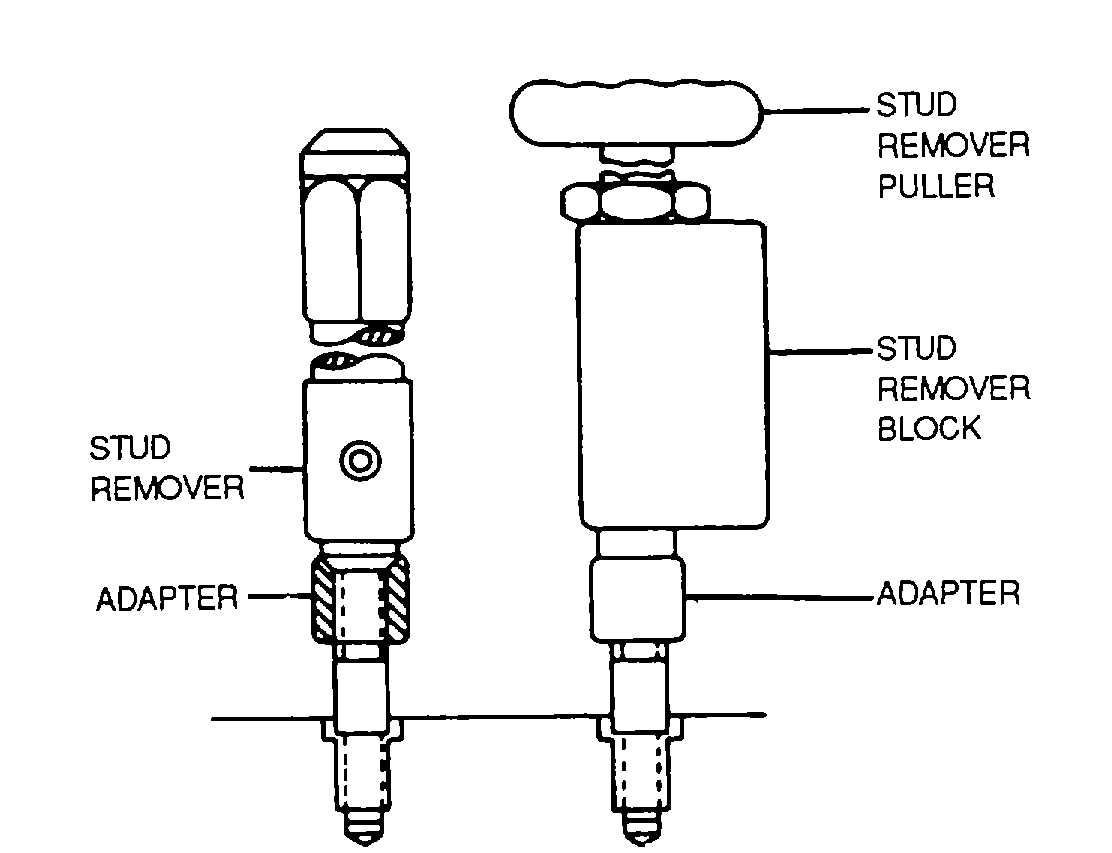

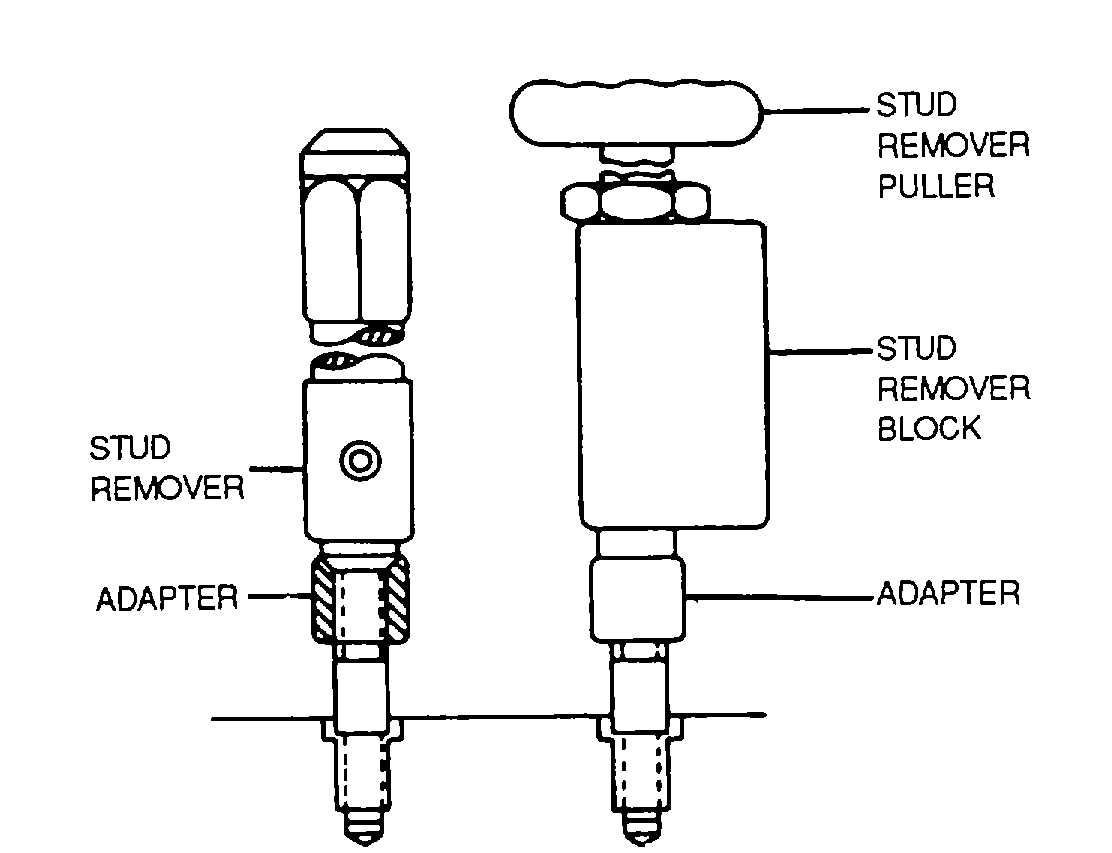

Figure 2-64. Stud Removal

NOTE

A drill jig recommended for

moderate

use

when

drilling

broken

studs

where

it

is

impractical to have a complete

set of stud replacement jigs.

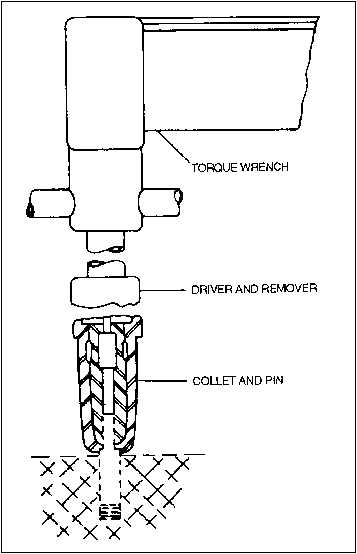

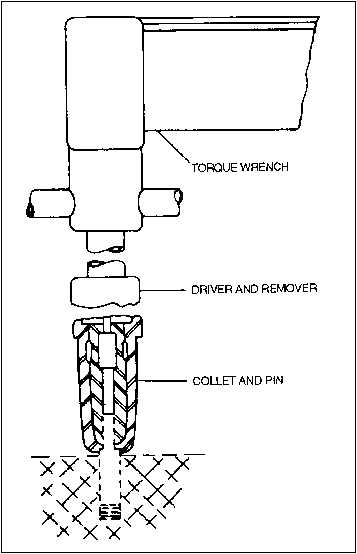

Figure 2-65. Stud Installation

(6)

Drill a pilot hole in stud, using 1/8-inch diameter

by 5-1/8 inch drill

(7)

If stud has a diameter of 7/16 inch or greater,

enlarge pilot hole in stud using 1/4-inch diameter drill.

(8)

Redrill hole in stud, using proper drill for stud

size.

(9)

Select proper removing tool for stud size

(10)

Drive removing tool into drilled hole in stud.

(11)

Remove stud, using tap wrench

Figure 2-65. Stud Installation

b. Installing New Stud. The procedures for retapping and installation are as follows.

CAUTION

Excessive amounts of lubricants shall be avoided, especially in blind

holes Use only sufficient lubricant to cover sides of threads with a thin

coating Excessive lubricant can prevent proper stud installation.

(1)

When replacing a stud with another stud of the same size, run proper size tap into hole to clean

up threads without removing any metal.

(2)

When retapping for next oversize stud, use proper tap for die-cut studs. If stud cannot be driven

at torque specified in applicable aircraft maintenance manual, retap with tap for rolled thread studs of same size.

NOTE

Unless otherwise specified, antiseize compound MIL-T-83483 shall be

applied in tapped holes.

(3)

Select proper size stud and install with driver and remover, and collet and pin, as shown in figure 2-65

(4)

Use torque wrench to determine torque at required height of stud.

2-55