TM 1-1500-204-23-6

Figure 2-57. Huck Rivet

(a)

Huck rivet allowable load. Loads allowable for Huck rivets are compared to those of

solid rivets of the same shear strength The composite ultimate shear strength of the 5056-H14 sleeve and 2024-T36 pin

exceeds 38,000 psi, based on standard rivet hole diameters, and over 28,000 psi tensile strength The positive

mechanical lock definitely eliminates any possibility of the pin working out under any conditions of vibration or fatigue

loading, regardless of whether rivet has been driven in a properly sized or oversize hole in thin sheets, shear strength will

be different for each thickness. On countersunk-head rivets, shear strength is approximately the same as for protruding-

head rivets when used in dimpled sheets in machine countersunk sheets, this value will be considerably lower.

(b)

Huck rivet identification. Use huck rivet part number to completely identify the rivet. A

typical example of a Huck rivet part number is P5C. The first selecter (P) of the part number indicates head type as a

universal-head (MS20470) rivet. The numeral (5) following the first letter indicates shank diameter in 1/32 inch, thus, 5

indicates a 5/32-inch diameter shank. The last letter (C) is the grip code letter which is stamped on the head of each

rivet pin. The letter indicates the grip range, which in this case is 0.077 inch to 0.107 inch. Another example of

identification is 100V6E 100V indicates a 100-degree counter sunk head (MS20426). The numeral 6 indicates that the

shank is 6/32 or 3/16 inch in diameter, and the letter E represents a grip range from 0 236 inch to 0.072 inch.

(4)

Olympic rivets. The rivets consist of a hollow manufactured rivet and stem. They are similar in

operation to Huck rivets. The part number is used to completely identify the rivet. A typical example of an Olympic rivet

part number is RV200-4-2. The RV indicates an Olympic blind rivet, while the numeral 2 describes the rivet as being

self-plugging. The first 0 indicates that the rivet is made of 2117 aluminum alloy; the number 5 here would identify the

material as 5056 aluminum alloy for use on magnesium surfaces. The second 0 describes the head style as universal,

the numeral 1 in this position would describe a 100-degree countersunk head. The first dash number is the rivet shank

diameter measured in 1/32-inch increments, and the second dash number is the grip length, which denotes maximum

thickness of material in which the rivet can be used, this measurement is made in 1/6-inch increments. The Olympic

rivet, part number RV200-4-2, is now identified as an Olympic blind rivet, self-plugging, made of 2117 aluminum alloy

with a universal head. It has a 1/8-inch shank and a 1/8-inch grip.

j.

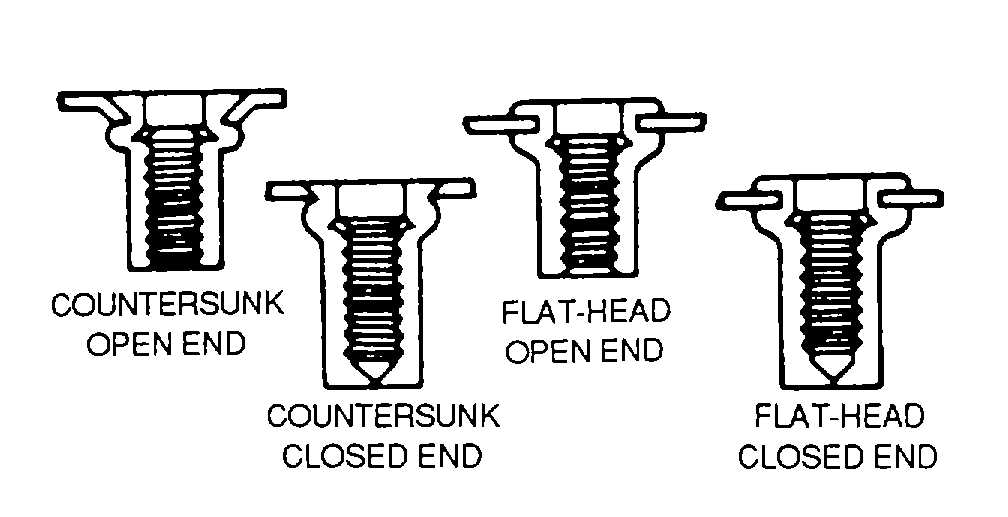

Rivnuts. Rivnuts are internally threaded and counterbored tubular rivets that can be headed blind in such

applications as the attachment of deicing boots. These special rivets can be made of either 6053 aluminum alloy, carbon

steel, alloy steel or corrosion resistant steel, with either flat or countersunk heads and open or closed ends, as shown in

figure 2-58. Each rivet type is available in various thread sizes. An example of a typical part number is: NAS

1329H3K130L. NAS 1329 indicates the basic standard to which a rivnut conforms. The letter between the military

specification number and the first dash number indicates material type and finish ("A" aluminum alloy, "S" for carbon

steel, "H" for alloy steel, and "C" for corrosion-resistant steel). The first dash number, after the material type, indicates

machine screw size of the thread A dash following the machine screw size indicates open end keyless, "B" indicates

closed end keyless, "K" indicates open end with a key, "KB" indicates closed end with a key. The final dash number

indicates grip range in thousands of an inch. The presence of an "L" at the end of the part number indicates a thread

locking feature.

Figure 2-58. Rivnut Types

2-51