TM 1-1500-204-23-6

i.

Blind Rivets. Blind rivets are designed for difficult riveting in places where access is possible to only one side of

the work CherryMAX, Huck, and Olympic rivets are explained in the following paragraphs.

(1)

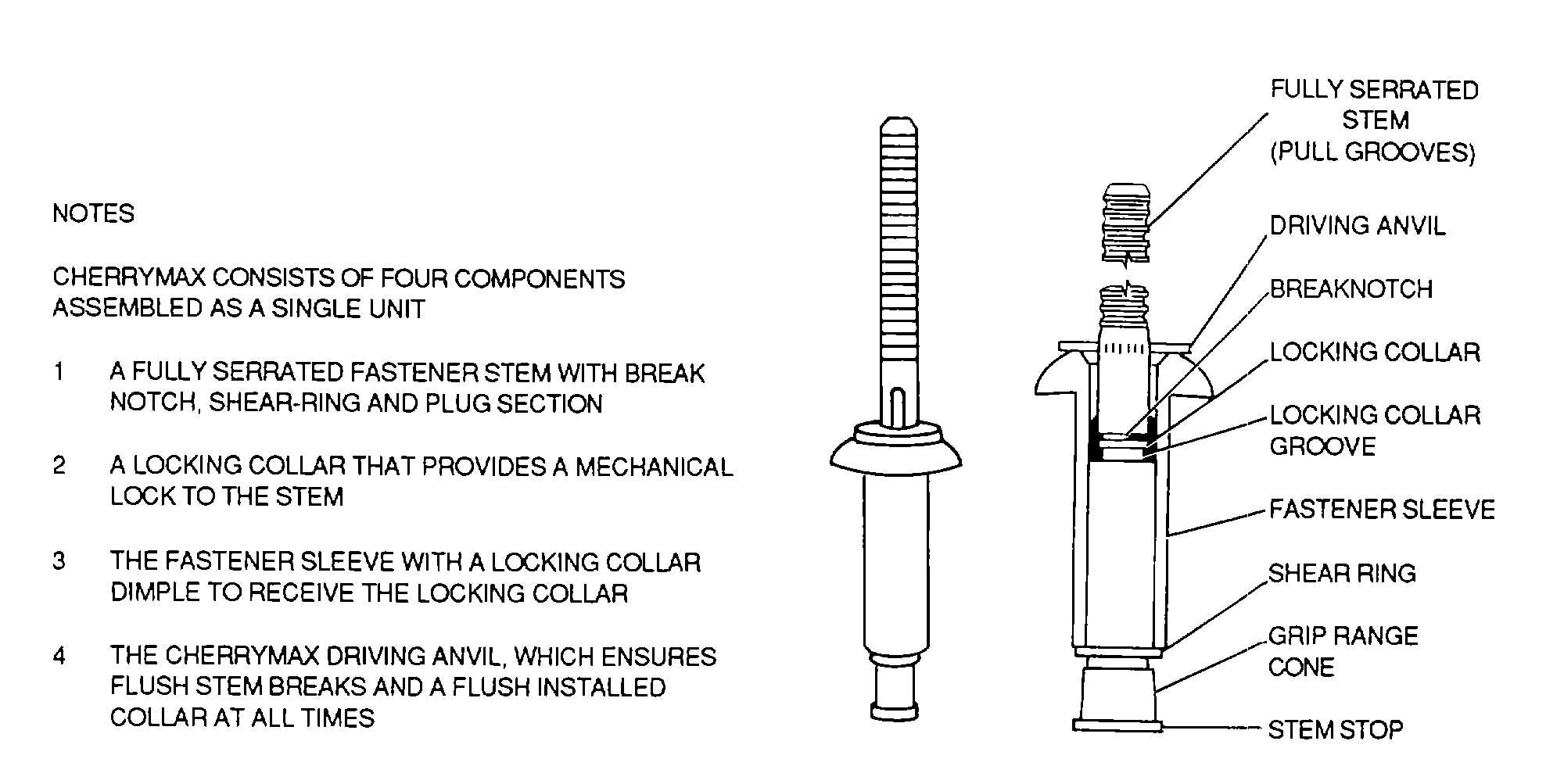

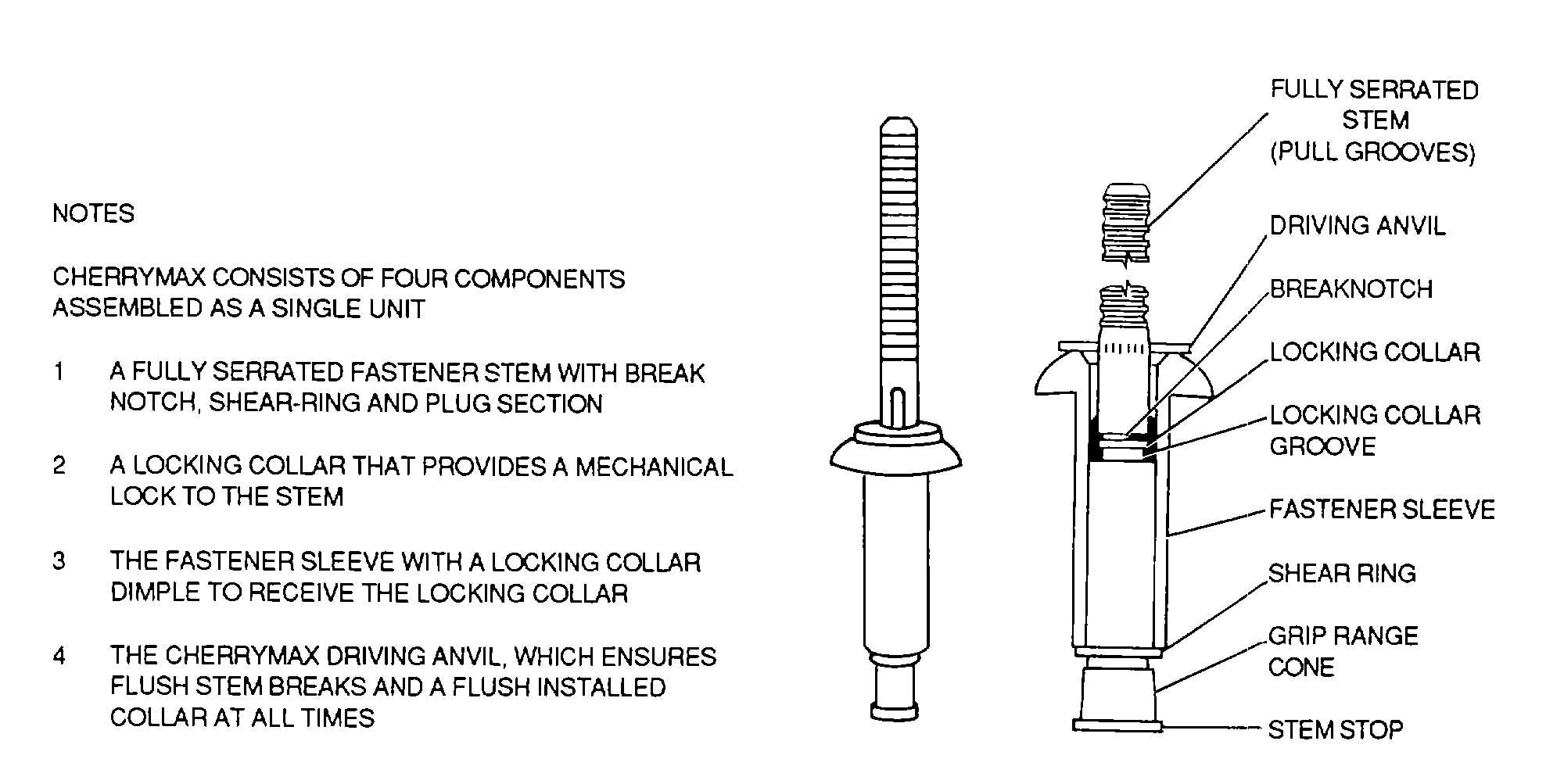

CherryMAX rivets These rivets, as shown in figure 2-55, are installed by one operator using a

special gun which exerts a pulling force to form a head on the blind side of the rivet. The CherryMAX rivet can be used

for all repair of Army aircraft involving the use and application of blind rivets The CherryMAX rivet should not be used to

replace solid rivets unless absolutely necessary. Properly installed CherryMAX rivets may be used to replace both 2117-

T4 and 2017T4 solid rivets size for size Shank and grip lengths of CherryMAX rivets are designed by dash numbers

following the series number. CherryMAX rivets are qualified to MIL-R007885C or rivet identification Refer to tables 2-10

and 2-11.

(2)

Cherrylock rivets. Cherrylock rivets NAS 1398 and 1399 and NAS 1738 and 1739, as shown in

figure 2-56, differ from MS20600 and MS20601 rivets in that they have a mechanically locked stem. This stem is

designed to break flush to eliminate stem trimming after installation The NAS 1738 and 1739 are designed for use in thin

and dimpled sheets, where a large head is needed. The NAS 1398 and 1399 are designed for thicker sheet needs.

(3)

Huck rivets Huck rivets consist of two parts a hollow sleeve made of 5056-H14 aluminum alloy

having a universal or countersunk head with a conical recess and locking collar at the other end, and a pin made of 2024-

T26 aluminum alloy which is pressed into the sleeve The pin is provided with an extruding angle and land to expand the

sleeve for hole filling, a breakneck groove, and a head The pull grooves on the protruding end of the pin fit the jaws of

the rivet tool. The rivet is shown in figure 2-57.

Figure 2-55. CherryMAX Rivet

2-48