NAVAIR 01-1A-505-2

003 02

TO 00-25-255-1

Page 5

TM 1-1500-323-24-2

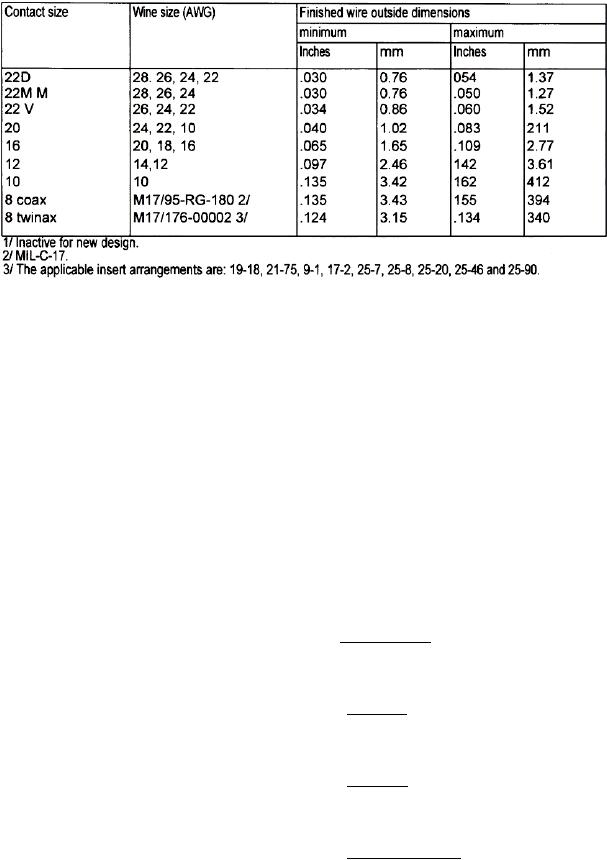

Table 1. Wire Sizes and Diameters

b. All series are designed to ensure proper

6. MATING SEAL. Plugs and receptacles with pin

orientation of the mating halves prior to closure.

inserts have a resilient face with individual pin barriers

so as to seal against the hard face socket insert. The

resilient interface seal provides individual contact seals

c. All series include hermetically sealed

in the mated condition between each contact and the

receptacles with fixed solder contacts.

shell. Series I, II, and III are provided with a peripheral

seal, and Series IV incorporates an o-ring seal.

d.

All series include EMI shielding.

7. SHELL. Shells, including mounting flanges, are of

e. Series I, III, and IV provide electrical

one piece construction and designed to retain their

continuity between mated shells prior to contact

inserts in one position by a mechanical means. Each

engagement with the contacts so located as to be

plug and receptacle has at least one blue color band,

protected from handling damage and inadvertent

which indicates rear release retention system, located

electrical contact (scoop proof).

so as to be readily visible.

f. S e r i e s I I p r o v i d e l o w s i l h o u e t t e f o r

8. COUPLING. Connectors shall be capable of being

minimum size and weight.

fully coupled and uncoupled without the use of tools.

9. Series I and II. A detent is provided in the coupling

4. WIRE SEALING. Wire sealing is accomplished by

mechanism so that an audible click is heard when

the use of a grommet seal designed to seal against the

proper coupling is complete.

inserted wire outside diameter. The outer diameter

shall be within the applicable size range as specified

10. Series III. Complete coupling is accomplished by

(Table 1).

clockwise rotation of 360 of the coupling nut to

provide metal to metal contact.

NOTE

11. Series IV. Complete coupling is accomplished by

All unwired contacts shall have sealing plugs

a clockwise rotation of 90 to a detent and provides an

installed.

audible click and an indication is felt.

5. GROMMET SEALING PLUGS. The grommets of

12. Visual Indication. On Series I and II, provision will

environment resistant connectors are designed to

be made for visual determination of complete

accept sealing plugs in accordance with MS27488 to

coupling. On Series III and IV, a red band is visible

be used where unwired contacts are placed. The

when not mated and not visible when fully mated.

connector when ordered as a unit, will have sealing

plugs enclosed so as to equal 10% of the number of

contacts but not less than one.