NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

008 02

1 September 2011

Page 21

NOTE

53. Broken Wire Contact Removal.

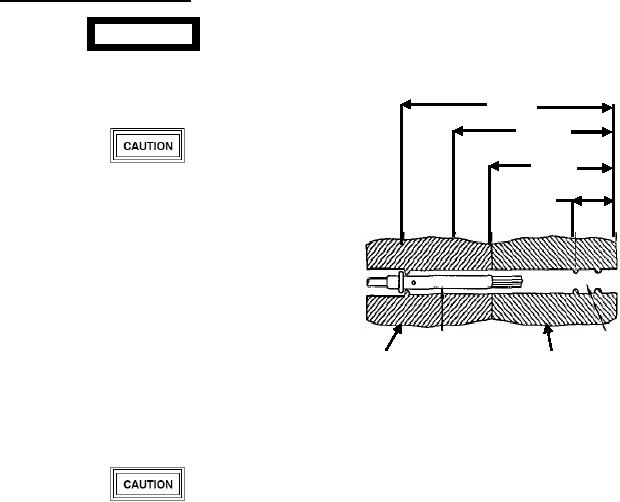

Refer to figure 19 for approximate

dimensions of a size 22 contact and cavity.

WARNING

The dimensions in this procedure are based on

a size 22 contact.

Metal tool tips are sharp and cause injury to

personnel and/or damage to connectors.

1/2 Inch

3/8 Inch

5/16 Inch

Present metal tooling in some instances has

1/8 Inch

damaged the wire sealing grommet at the end

of the connectors. Plastic tools are preferred.

Caution should be exercised in the use of

tooling.

Inspect tips of metal tools for distortion of

probe before use as connector damage can

Contact Wire Barrel

occur.

Seal Area

Resilient Rear

Plastic Retainin g

Insert

a.

Select correct removal tool (Table 4, 6 or 7).

Insert

b. Insert tip of removal tool about l/8 inch into

Figure 19. Typical Connector Dimensions

cavity at rear of connector.

c. Gently insert removal tool into cavity in about

1/16 inch units, releasing tool after each unit if resistance

is felt.

Wire strands may be encountered at any point

NOTE

up to 5/16 inch of tool insertion. It is

important not to jam any strands of wire up to

Rotating removal tool works splayed wire

this point.

strands into slot of tool, allowing tool to pass.

Withdraw removal tool anytime during

Removal tool may be blocked at rear of

insertion when it cannot be advanced into

contact by plastic insert or additional strands

connector using these procedures. Inspect tool

of broken wire.

tip for nicks, cracks, mushrooming, and other

damage that will prevent is functioning.

d. If resistance is felt before removal tool reaches

Replace removal tool and repeat procedure, if

back end of contact, withdraw tool slightly, rotate about

required.

l/6 of a turn, and reinsert tool. Repeat rotating and

insertion procedure until tool passes with minimum

additional force to 5/16-inch depth back end of contact

(Figure 19 and 20).