TM 1-1520-264-23

Change 1 2-38.1

2.16.1.1

STRAP PACK OUTBOARD BOLT INSPECTION (UT)

2.16.1.1.1 Description. The four strap pack outboard bolts are made of PH13-8 MO steel and

are secured by a pin to the lead lag link and pitch housing.

2.16.1.1.2 Defects. This inspection is used to detect inside and outside diameter

circumferential cracks in the shank of the strap pack bolt.

2.16.1.1.3 Primary Method. Ultrasonic specific.

NOTE

This inspection procedure and graphics shall be reviewed in its entirety prior to

performing the inspection. The supplemental training CD ROM should also be

reviewed in conjunction with performing this procedure.

2.16.1.1.3.1 NDI Equipment and Materials. (Refer to Appendix B)

a. Ultrasonic Inspection Unit, USD 15S/AF

b. Transducer, 15.0 MHz, longitudinal wave, 1/8 in. x 1/8 in. element

c. Transducer Positioner

d. Cable Assembly, BNC to Microdot

e. Consumable Materials, refer to Table 1-8

f. Aircraft Marking Pencil, refer to Table 1-8

2.16.1.1.3.2 Preparation of Helicopter. The helicopter shall be prepared for safe ground

maintenance. The lead lag link shall be removed in accordance with TM 1-1520-238-23.

2.16.1.13.3 Access. Access to the strap pack outboard bolt can be accomplished by removal

of the main rotor blade and the lead lag link in accordance with TM 1-1520-238-23.

2.16.1.1.3.4 Preparation of Part. The part shall be thoroughly cleaned. Refer to Preparation of

Part for NDI, paragraph 1.4.4.

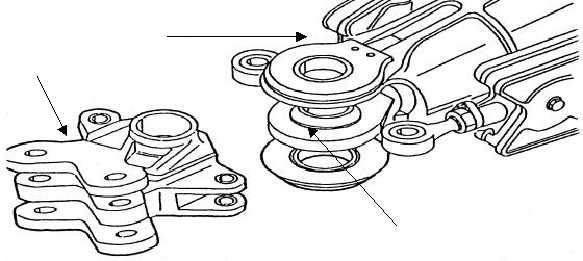

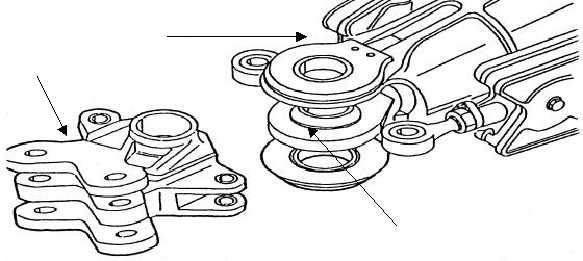

Lead Lag Link

Pitch change housing

Strap Pack Outboard Bolt