TM 1-1520-264-23

2-38.6 Change 1

(i) Continue the rotation of the POSITIONER to locate the lower ID EDM

notch. Adjust the gain to achieve a signal height of 60% FSH. Rotate the

transducer carefully to minimize base line noise if necessary. Tighten the

set screw.

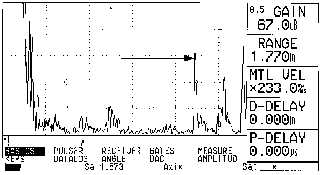

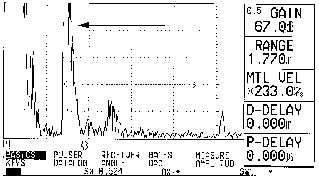

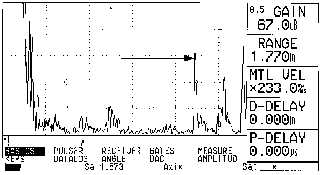

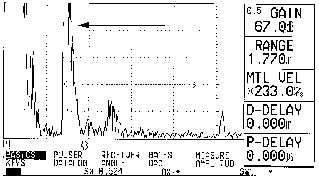

(j) Rotate the POSITIONER 360 degrees to verify both upper and lower ID signals

are readily identifiable and break the gate threshold. Reference Figure 7 for

upper and lower ID EDM notch displays.

Figure 7a. Upper ID notch

Figure 7b. Lower ID notch

(3)INSPECTION PROCEDURE

(a) Perform the OD inspection scan after completion of the OD

calibration. Make two complete revolutions with the transducer in

the OD position.

(b) Perform the ID inspection scan after completion of the ID calibration

procedure. Make two complete revolutions with the transducer in the

ID position.

(c) Perform the calibration set up every time prior to inspecting the ID or

OD of a new bolt.

NOTE

The thin couplant layer is only adequate for approximately two passes

without signal amplitude loss. Excessive couplant under the positioner can

also create noise and erroneous signals on the CRT. When in doubt clean

the bolt, reapply couplant, and rescan.

(4) ACCEPTANCE/REJECTION CRITERIA

Relevant signals exceeding the 40% gate threshold are rejectable. ID

or OD cracks can appear anywhere within the gated area. Cracks may

be detected on both the ID and OD surfaces with either scan. The

signal received from a small crack will usually have a very quick rise

and fall time when scanning. A legitimate crack indication will have a

consistent location on the bolt perimeter and can be easily repeated on

subsequent rescans. Verify all indications by cleaning the bolt,

reapplying couplant and rescanning.

(5) POST CLEAN

Clean the bolt with a cloth dampened with water to remove couplant

residue.

Lower ID

Upper ID