TM 1-1520-264-23

Change 1 2-38.5

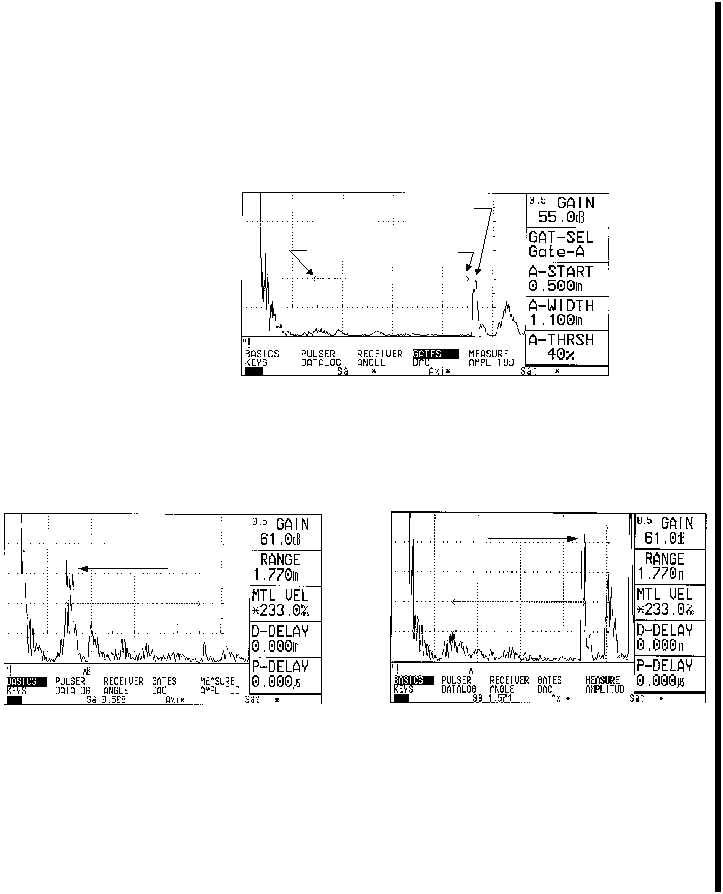

(d) Rotate the positioner away from the upper OD EDM notch, and

note the position along the time base line of the signal received

from the thread run- out groove. This signal is located just outside

the gate on the right hand side of the CRT. Moisten a finger with

couplant and damp this

signal to gain familiarity. The

appearance and amplitude of this signal is dependent upon the

radius of the thread run-out groove. A large signal will be generated

from a sharper edge, as a lesser or nonexistent signal would be

indicative of a smoother transition area. Reference Figure 5.

Figure 5. Signal from thread run-out groove

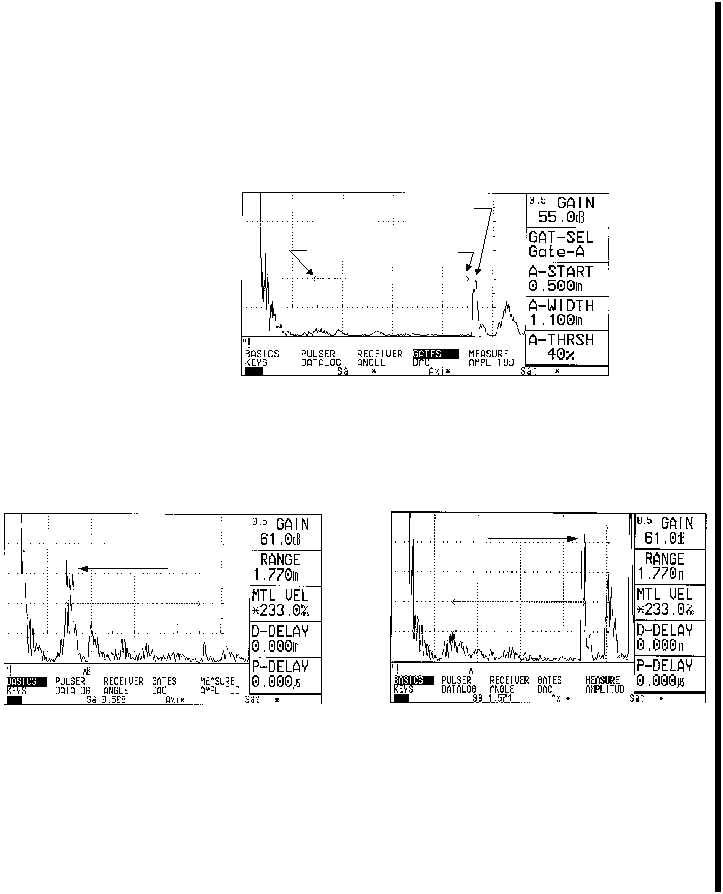

(e) Again rotate the POSITIONER 360 degrees to confirm the

electronic gate positioning and verify the upper and lower OD

EDM notches break the gate threshold. Referenc e Figure 6 for CRT

displays of upper and lower outside diameter EDM

notches.

Figure 6a. Upper OD EDM notch

Figure 6b. Lower OD EDM notch

(f) Perform the OD inspection scan after completion of the OD calibration.

Make two complete revolutions with the transducer in the OD position.

(g) Upon completion of the OD scan, wipe the calibration standard clean,

reapply couplant, and place the positioner on the calibration standard.

(h) Place the transducer in the ID guide hole. Rotate the POSITIONER, and

identify the signal obtained from the upper ID EDM notch.

Gate

Thread run-out

Gate

Upper OD

Lower OD