TM55-1500-345-23

Right and Methods of Spraying

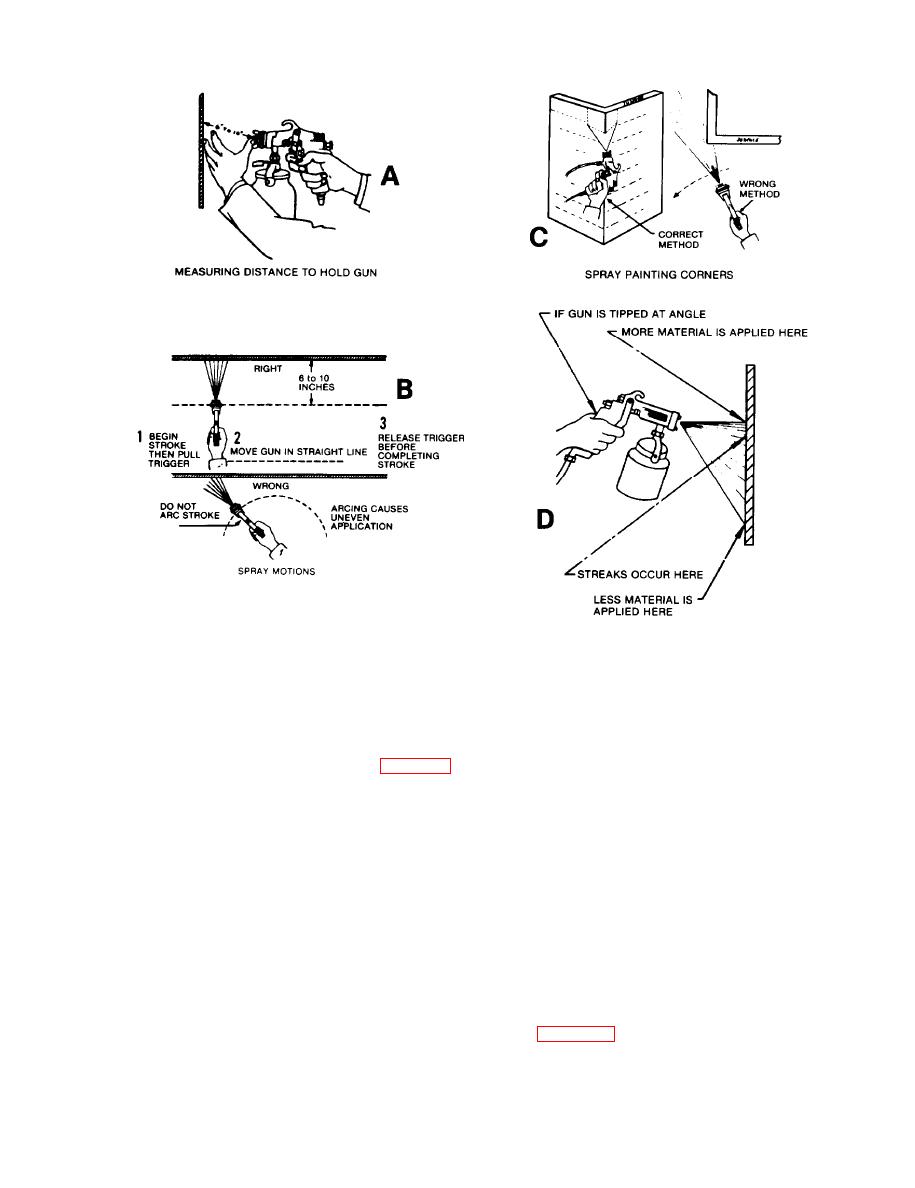

the work, the same speed, and as near to a right

poor flow characteristics (such as MIL-C-46168),

angle to the surface as possible throughout the

that the gun is held perpendicular to all surfaces

entire pass. The natural tendency for spray paint-

(flat or contoured as they are passed).

ers, particularly when fatigued or in an uncomfort-

If this is not done, the irregular spray pattern form-

able position, is to arc or wave the gun (figure 3-l).

ed will lay down uneven thicknesses. Uneven

This practice must be avoided at all costs, In gen-

thickness will cause uneven drying when using

eral, wrist movement must be eliminated in strok-

single component paint. Uneven thickness, when

ing. A flexible wrist almost inevitably causes the

MI L-C-46168 paints are used may cause sagging.

gun to describe a curve instead of remaining par-

Protrusions such as screw heads, etc., present

allel to the surface. This causes a thicker coating

surfaces that will require facing the gun in several

to be applied in the middle of the stroke than at

directions to completely coat them. It may be ad-

the end. (An exception to the rules is in spotting

visable to spot paint these in advance. The rate of

during touchup. Here it is permissible to fan the

the stroke should be uniform and such as to lay

gun to lay down a spot which is thinner at the

down a full wet coat of material. Stroking should

edges in order to blend into the larger painted

be in parallel passes with each stroke aimed for a

area.) Touch up here applies only to painting

50 percent overlay, or so that the middle of the

occuring in an approved facility and not open air

spray strikes the wet bottom edge of the previous

touch up, Special pains must be taken, particu-

stroke (figure 3-3.)

larly when applying dense coating materials with