TM55-1500-345-23

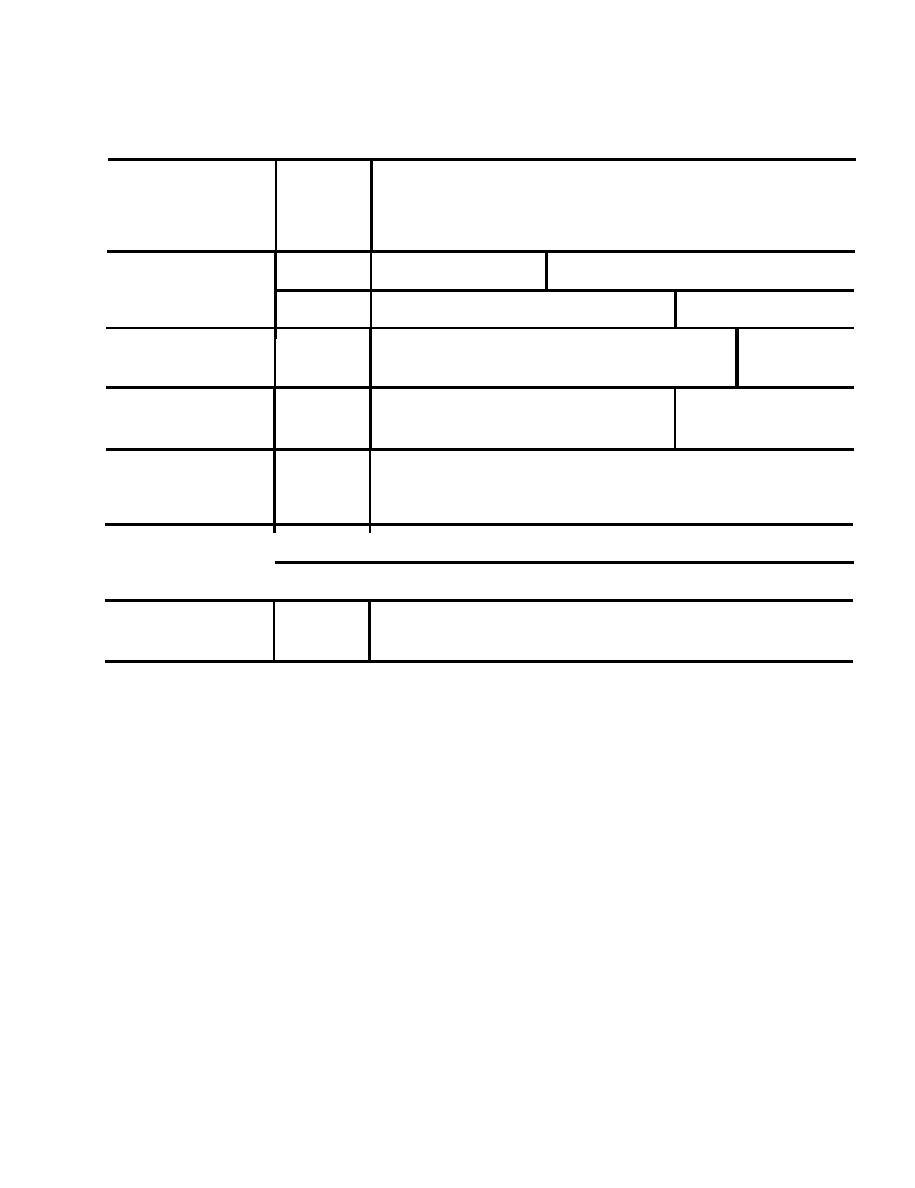

MI L-C-46168B Paint

Maximum

Application Safety Procedures

Crossdraft

Type Of Painting

(Feet per

Facility

Minimum Cross-Section Air Flow Velocity (Feet per Minute)b

Minute) b

25

75

100

125

150

175+

50

Walk-in Room or Deep

50

Chemical Cartridge Respirator

Airline Respiratorc

Booth (e. g., Vehicular

Booth)

100

Airline Respiratorc

Chemical Cartridge Respirator

I

100

Chemical Cartridge

Spray Cabinet (Less Than

Airline Respiratorc

Respirator

4 ft2 Open Face Area)

100

Spray Booth (More Than

Chemical Cartridge

Airline Respiratorc

4 ft2 Open Face Area)

Respirator

Confined Spaces (e.g.,

------

Inside or Underneath

Airline Respiratorc

Vehicle)

-- --

Chemical Cartridge Respiratord

Outdoor application

I

I

------

-- Spray

Airline Respiratorc

I

I

Indoor Application

------

Airline Respiratorc/ Facility Dedication/No Unprotected Personnelf

(No Validation)

Worker protection also includes full skin cover clothing and gloves. exclusion of sensitized personnel

a

and job-related medical surveillance.

Feet per minute = ft3/min/ft 2 of open face area perpendicular to air flow.

b

Airline respirator = NIOSH/MSHA-approved Type C positive-pressure airline hose mask with full face-

c

piece.

Chemical cartridge respirator = NIOSH/MSHA-approved paint spray respirator with organic vapor car-

d

tridge(s), paint/mist prefilter(s), and full facepiece. Cartridges and prefilters are to be replaced when

one of the following occurs:

-- new workday begins

-- chemical or solvent odor is detected inside mask by wearer

-- breathing resistance becomes too great

Unprotected personnel should remain outside a 50-ft radius until 30 minutes after painting is com-

e

pleted.

f Exclusion of unprotected personnel during painting and for 30 minutes after cessation of painting.